Question: Compute Net Present Value: Essen Manufacturing Company is evaluating a proposal to purchase a new drill press as a replacement for a less efficient machine

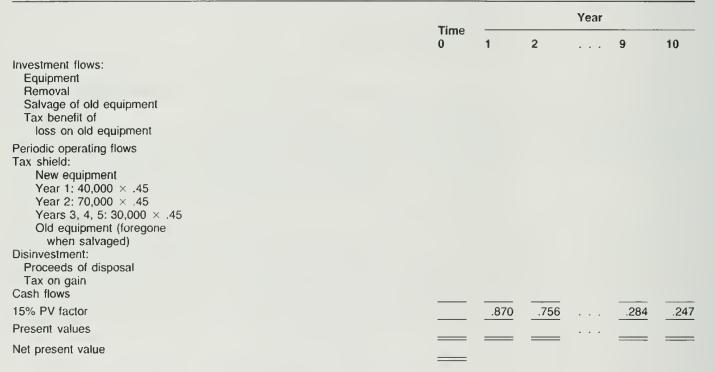

Compute Net Present Value: Essen Manufacturing Company is evaluating a proposal to purchase a new drill press as a replacement for a less efficient machine presently in use. The cost of the new equipment in Time 0 including delivery and installation. is $200,000. If the equipment is purchased, Essen will incur costs of $5,000 to remove the present equipment and revamp its facilities. Depreciation for tax purposes will be allowed as follows: Year 1, $40,000: Year 2. $70,000; and $30.000 per year in each of Years 3-5. The existing equipment has a book and tax value of $100,000 and a remaining useful life of 10 years. However, the present equipment could be sold for only $40,000. The old equipment is being depreciated for book and tax purposes using the straight-line method over its actual life.

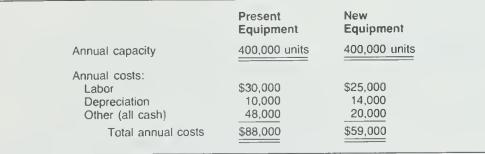

Management has provided you with the following comparative manufacturing cost data:

The existing equipment is expected to have no salvage value. The new equipment is expected to have a salvage value of $60,000 at the end of 10 years, which will be taxable. No changes in working capital are required with the purchase of the new equipment. The sales force does not expect any changes in volume of sales over the next 10 years. The company's cost of capital is 15 percent, and its tax rate is 45 percent.

Required:

a. Calculate the equipment removal costs net of tax effects.

b. Complete a depreciation schedule like the one in Illustration 15-12.

c. Compute the foregone tax benefits of the old equipment.

d. Calculate the cash inflow, net of taxes, from the sale of the new equipment in Year 10.

e. Calculate the tax benefit arising from the loss on the old equipment.

f. Compute the annual differential cash flows arising from the investment in Years 1-10. g. Complete the following schedule and compute the net present value of the project.

Present Equipment New Equipment Annual capacity 400,000 units 400,000 units Annual costs: Labor Depreciation $30,000 $25,000 10,000 14,000 Other (all cash) 48,000 20,000 Total annual costs $88,000 $59,000

Step by Step Solution

3.53 Rating (150 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts