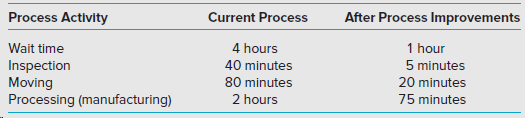

Question: ABC Mfg. is evaluating the desirability of implementing process improvements and is seeking your help in determining whether it should proceed with the proposed improvements.

Required

1. Determine the manufacturing (production) lead time (in minutes) for each of the two decision alternatives.

2. Determine the manufacturing cycle efficiency (MCE) for each decision alternative. (Round decimal answers to 2 places, e.g., 0.3143 = 0.31.)

3. Calculate (to 2 decimal places each) the following: (a) the percentage improvement in MCE, new vs. old, and (b) the ratio of the new manufacturing lead time to the old manufacturing lead time, in decimal form (e.g., 0.4275 = 0.43).

4. Based on only the figures calculated in requirements 1, 2, and 3, should the company implement the proposed process improvements? Why or why not?

5. Why would process improvements, such as those referenced above, likely lead to improved financial results?

Process Activity Current Process After Process Improvements 1 hour 5 minutes Wait time Inspection Moving Processing (manufacturing) 4 hours 40 minutes 80 minutes 2 hours 20 minutes 75 minutes

Step by Step Solution

3.26 Rating (175 Votes )

There are 3 Steps involved in it

The following material from Chapter 14 serves as useful background for responding to the requirements of Exercise 1756 EXHIBIT 1414 Model of CustomerResponse Time CRT 1 Manufacturing production cycle ... View full answer

Get step-by-step solutions from verified subject matter experts