An experiment was run in a semiconductor fabrication plant in an effort to increase yield. Five factors,

Question:

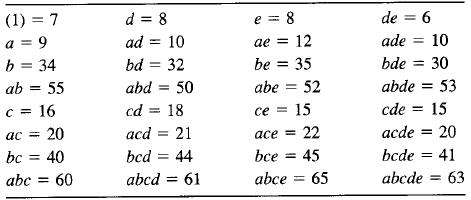

An experiment was run in a semiconductor fabrication plant in an effort to increase yield. Five factors, each at two levels, were studied. The factors (and levels) were A = aperture setting (small, large), B = exposure time (20% below nominal, 20% above nominal), C = development time (30 s, 45 s), D = mask dimension (small, large), and E = etch time (14.5 min, 15.5 min). The unreplicated 25 design shown below was run.

(a) Construct a normal probability plot of the effect estimates. Which effects appear to be large?

(b) Conduct an analysis of variance to confirm your findings for part (a).

(c) Write down the regression model relating yield to the significant process variables.

(d) Plot the residuals on normal probability paper. Is the plot satisfactory?

(e) Plot the residuals versus the predicted yields and versus each of the five factors. Comment on the plots.

(f) Interpret any significant interactions.

(g) What are your recommendations regarding process operating conditions?

(h) Project the 25 design in this problem into a 2k design in the important factors. Sketch the design and show the average and range of yields at each run. Does this sketch aid in interpreting the results of this experiment?

Step by Step Answer: