Basic Manufacturing, a maker of hose fittings, uses point of action controls on the plant floor to

Question:

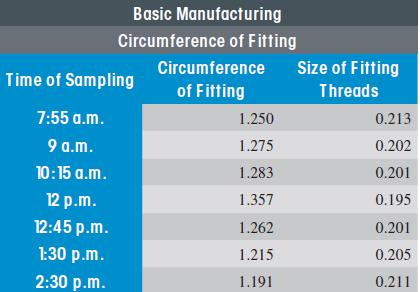

Basic Manufacturing, a maker of hose fittings, uses point of action controls on the plant floor to help its workforce stay on target to continuously improve performance. Two measures are made for each hose fitting made: circumference of fitting and thickness of the threads, which screw on to a hose to make a leakproof fitting. The circumference is targeted for 1.25 inches with an upper allowable size of 1.3 inches and a lower allowable size of 1.2 inches. The thickness of the threads is targeted for 0.2 inches with an upper limit of 0.21 inches and a lower limit of 0.19 inches. The table below has the actual measured circumference and thread thickness for the day ’s production.

REQUIRED:

a. Make a Shewhart control chart for the circumference variable. Plot each of the observations on your control chart by time.

b. Make a Shewhart control chart for the size of the threads variable. Again, plot each observation by time.

c. Right now, Basic only resets the calibration on its machines at the start of the day and at lunchtime. Given the results from your control charts, do you feel it should recalibrate the machines more regularly or stop the line whenever the observation falls out of range to adjust the machines? Why?

Step by Step Answer:

Managerial Accounting An Integrative Approach

ISBN: 9780999500491

2nd Edition

Authors: C J Mcnair Connoly, Kenneth Merchant