Bright Lights, Inc., makes a variety of lamps. It is very important that the base of the

Question:

Bright Lights, Inc., makes a variety of lamps. It is very important that the base of the lamp fits snugly to the body if the customer is going to be satisfied with the look of the lamp itself. While there is a tightening mechanism on top, if the base is not close to an exact fit for the body of the lamp, the product is a reject.

Juan Hernandez, president of Bright Lights, has been getting concerned about the number of customer complaints and product returns for the main line of the company, Quality Lights. This is a premium product where there is no room for error in design or production, but errors have been creeping in. The company keeps a tight control on its production facilities, but the engineers have designed each lamp to be made within specified parameters. The two main parameters are width and circumference. Both are critical for the lamp body to fill the frame properly.

To address this problem, Juan decides to pull together his quality team. This includes Barb Haverhill, VP of manufacturing; Frank Burns, VP of marketing; and Joel Dempski, director of quality. The meeting does not go well from the start.

Barb: We are making our products within specifications. We are constantly taking readings and we fill more Shewhart control charts in a day than any other company I’ve ever worked for. We’re staying within spec, I swear.

Frank: If that’s true, Barb, why are we getting so many units returned to us? My salespeople are ready to mutiny, because the brand image is getting tarnished. How can we ask a premium price for a product that just doesn’t look right?

Joel: Wait, I have to agree with Barb here. We’re meeting the specs set up by engineering, so if you want to blame someone, blame them.

Juan: I didn’t call this meeting to pin blame. We have a problem. The base and body aren’t coming together properly. Every return costs us anywhere from $150 to $250 directly, and at least four times that in lost reputation. I’d say this problem is costing us $1,000 every time it occurs. I don’t want excuses or blame, I want solutions.

Joel: We could try something new. I just learned about Taguchi loss function in the last quality class I took. It looks at variation in a much more precise way. What it basically says is that variation costs money even when it’s small. We could use that method instead of Shewhart charts to see what our quality picture looks like.

Barb: Are you telling me I have to send my crews to stat class to find a solution to Juan’s problem? We’re already measuring. How is this different?

Joel: It’s different because we put a higher cost on variation the farther the problem is from the exact measure. We could be in spec on both the base and the body and still have huge gaps (in the customer’s eyes) when we put the two together.

Frank: I think you should give this a try. Otherwise we may all be looking for new jobs as we lose our quality niche in the market.

Juan: I agree with Frank. Joel, you need to work with Barb and her teams to find the easiest way to implement this. Let’s look at both parameters, width and circumference, to see where our problems are.

Joel: I’ll assume you want to use $1,000 for the actual cost of a problem when we don’t meet spec dead on? I need this number for the formulas to work. Then, Barb, your team will simply measure a bit more often and still chart the results. You and I can put our heads together to solve the actual underlying equation. It’s simple once you have a target value, which we have, and actual observations.

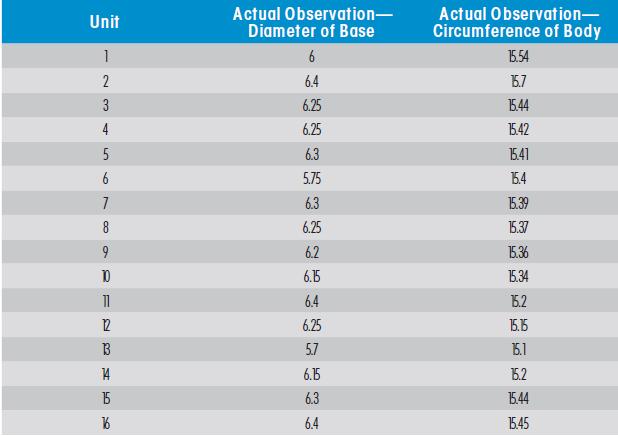

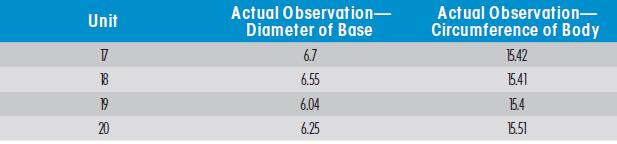

Barb: I’ll have to trust you, Joel. I’m not that comfortable with statistics, but this is important enough that I may have to learn something new. We’ll start charting every fifth unit instead of every 20, and we’ll measure both circumference of the body and the diameter of the base, since you say they both matter. We’ll get some use out of those calipers you bought us, Juan.

Juan: Thank you all for working together on this. I’d like to hear back in a week to see how bad our problem really is. Frank, tell marketing to keep collecting information for us, too. We need to know what is going wrong here, and quickly. The data Barb and her team collected for the first 20 observations of circumference of the body and diameter of the base are in the tables below. The target value for the lamp being studied is a diameter of six inches, and therefore, the target value for the circumference of the body is 15.7 inches.

REQUIRED:

a. Compute the Taguchi loss function for both key measurements of a lamp. What do your results tell you?

b. Looking at the numbers themselves, can you see a pattern of interaction that might be troubling? What is it?

c. What would you report back to Juan at the end of this trial run? Please be specific as to how you think the company should address its quality challenges using a business case structure to support your arguments.

Step by Step Answer:

Managerial Accounting An Integrative Approach

ISBN: 9780999500491

2nd Edition

Authors: C J Mcnair Connoly, Kenneth Merchant