Radnor Industries makes a variety of small one- to four-cup automatic coffeemakers that are used by hotels

Question:

Radnor Industries makes a variety of small one- to four-cup automatic coffeemakers that are used by hotels and in some residential settings for people who just need that quick jolt of caffeine to get their day started. It is critical that the machines are durable and work properly as they are often situated on the same desk as someone’s laptop computer in a hotel room. Nothing can make a hotel guest more frustrated than puddles of water everywhere and a mess to clean up before they even get their day going.

Even though quality is known to be critical, Jack Wallace, the company owner, has recently been receiving customer complaints that the machines are leaking and also making very weak and lukewarm cups of coffee, suggesting the water is not getting heated enough. The machines also seem to be breaking easily with use, making it very expensive for the hotels to offer their free coffee service in the guests’ rooms.

Jack calls together his key managers to see if they can get to the bottom of the problem. The conversations do not go well.

Sam Sneed, VP of marketing: You guys in manufacturing are killing us! There’s a lot of competition out there for small coffeemakers, and ours used to be one of the best. Now? We’re getting a terrible reputation for leaky, easily broken machines that make awful coffee. It’s not the coffee grounds that are the problem, believe me. It’s our machines!

Rudy Gentry, VP of manufacturing: Sam, you’re exaggerating once again. Our machines have a few problems, but we run a quality shop. I think our problem lies in poor design and poor pilot testing.

George Colby, director of product development: Come on, guys. Product development is not going to eat the problems on this one. We’re using tried and true engineering standards for coffeemakers, good materials, and good designs. If they’re leaking or not making coffee right, it’s a materials or manufacturing problem, not design!

Judy Dean, director of purchasing: I’m not going to let this be blamed on my group! We purchase according to specifications. Sure, we try to find some materials that may be a bit cheaper, but that’s how we’re rewarded! We make sure the materials meet our buying criteria. So if the engineered specifications aren’t tight enough, it’s sure not our fault!

Jack: Whoa! I didn’t call this meeting to set up a round robin blame game. I’m more concerned now than I was when we started as it seems no one has a clue as to why our units are failing in the field. If we’re purchasing materials that don’t work, this has to stop! Let’s change our reward structure if that is where it’s leading us. And design has to be more focused on setting tight, clear standards in place so purchasing and manufacturing can get the job done right. Beth White, controller: Jack, I have a suggestion. Why don’t we put together some cost of quality information and see if we can spot where the biggest problems appear to be in-house and with our customers? It won’t be an answer to the problem, but at least it will help us see where the issues are coming up internally.

Jack: Thank you for putting in something positive, Beth. I want all of you in this room to cooperate with Beth while she tries to start putting some shape around this problem for us. I also want Engineering to look at other ways we can start measuring and managing quality here in the shop. We have to get a handle on this problem or we’ll all be looking for a new job. And, I want you all to start working like a team. I mean it! I want team players and I intend to have them!

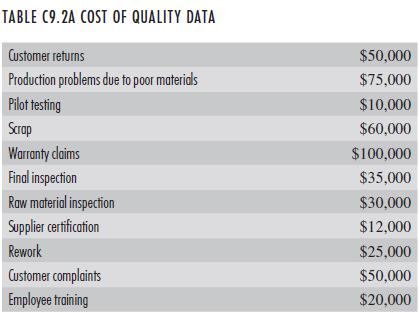

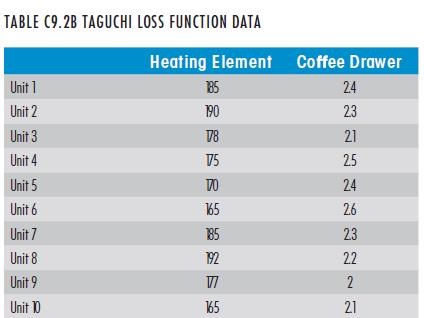

With that, the meeting broke up with everyone jostling to get out of the conference room door first. In the next week, Beth and her accounting analysis team set out to collect data. The information she gathered included both cost of quality information (see Table C9.2a) and some data from Engineering on the Taguchi loss function (see Table C9.2b). She now needs your help to compile this information into something useful for the next meeting with Jack.

For the Taguchi loss function, it was determined that a failure in the field would cost the firm 10 times the actual cost of the unit because of the reputation effect poor quality is having on sales. This means the constant cost of external failure is $100. The specifications that are determined to matter are the heating temperature of the coils and the size of the coffee “drawer” that holds the pod of coffee grounds (this is where the leaks are happening). The target value for the heating element is 190 degrees while the size of the coffee drawer is supposed to be 2.5 inches.

REQUIRED:

a. Prepare the cost of quality report for Radnor Industries. Make sure the report shows both total costs and percentage of total quality costs for each item in the report.

b. Calculate the Taguchi loss function for the two parameters given.

c. Where do you see the problems lying?

d. How is Jack going to get his team working together to solve these problems? Try to think of how incentives and performance evaluation can be used to sort out the team conflicts and get everyone working toward solving the company’s problems.

e. Draft a short memo to Jack with the results of your analysis and your suggestions for management changes to help bring quality into line. Use a business case structure to organize your argument.

Step by Step Answer:

Managerial Accounting An Integrative Approach

ISBN: 9780999500491

2nd Edition

Authors: C J Mcnair Connoly, Kenneth Merchant