Question: Reconsider Prob. 1815. Using an appropriate software, investigate the effects of the heat transfer coefficient and the final plate temperature on the time it will

Reconsider Prob. 18€“15. Using an appropriate software, investigate the effects of the heat transfer coefficient and the final plate temperature on the time it will take for the plate to reach this temperature. Let the heat transfer coefficient vary from 5 W/m2·K to 25 W/m2·K and the temperature from 30°C to 200°C. Plot the time as functions of the heat transfer coefficient and the temperature and discuss the results.

Data from 18-15.

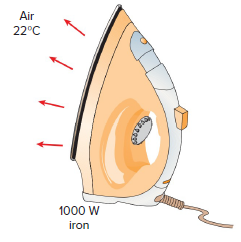

Consider a 1000-W iron whose base plate is made of 0.5-cm-thick aluminum alloy 2024€“T6 (r = 2770 kg/m3, cp = 875 J/kg · K, α = 7.3 × 10€“5 m2/s). The base plate has a surface area of 0.03 m2. Initially, the iron is in thermal equilibrium with the ambient air at 22°C. Taking the heat transfer coefficient at the surface of the base plate to be 12 W/m2·K and assuming 85 percent of the heat generated in the resistance wires is transferred to the plate, determine how long it will take for the plate temperature to reach 140°C.

Air 22C 1000 W iron

Step by Step Solution

3.50 Rating (167 Votes )

There are 3 Steps involved in it

Prob 1815 is reconsidered The effects of the heat transfer co... View full answer

Get step-by-step solutions from verified subject matter experts