Redesign the fractionator of Example 6.8 for a reflux ratio that is twice the minimum. Determine the

Question:

Redesign the fractionator of Example 6.8 for a reflux ratio that is twice the minimum. Determine the diameter of the tower, the height of packing in the stripping and rectifying sections, and the total gas-pressure drop. Design for a gaspressure drop not to exceed \(400 \mathrm{~Pa} / \mathrm{m}\).

Data From Example 6.8:-

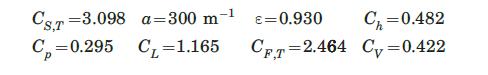

Determine suitable dimensions of packed sections of a tower for the benzene– toluene separation of Example 6.4, using Montz B2-300 metal structured packing. Design for a gas-pressure drop not to exceed 400 Pa/m. The hydraulic and mass transfer characteristics for this packing are (Billet and Schultes, 1999)

Data From Example 6.3:-

A trayed tower operating at 1 atm is to be designed to continuously distill 200 kmol/h (55.6 mol/s) of a binary mixture of 60 mol% benzene, 40 mol% toluene. A liquid distillate and a liquid bottoms product of 95 mol% and 5 mol% benzene, respectively, are to be produced. Before entering the column, the feed—originally at 298 K—is flash-vaporized at 1 atm to produce an equimolal vapor–liquid mixture (VF/F = LF/F = 0.5). A reflux ratio 30% above the minimum is specified. Calculate: (a) quantity of the products; (b) minimum number of theoretical stages, Nmin; (c) minimum reflux ratio; (d) number of equilibrium stages and the optimal location of the feed stage for the reflux ratio specified; and (e) thermal load of the condenser, reboiler, and feed preheater.

Step by Step Answer: