The cooling water flow rate to the condensers of a big coal-fired power plant is (8970 mathrm{~kg}

Question:

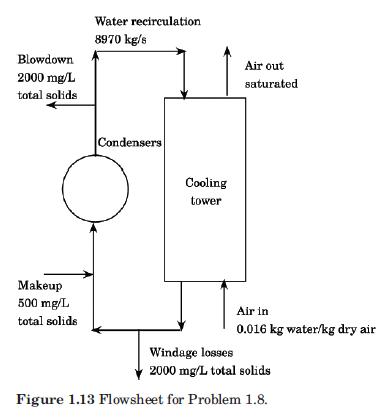

The cooling water flow rate to the condensers of a big coal-fired power plant is \(8970 \mathrm{~kg} / \mathrm{s}\). The water enters the condensers at \(29^{\circ} \mathrm{C}\) and leaves at \(45^{\circ} \mathrm{C}\). From the condensers, the water flows to a cooling tower, where it is cooled down back to \(29^{\circ} \mathrm{C}\) by countercurrent contact with air (see Figure 1.13). The air enters the cooling tower at the rate of \(6500 \mathrm{~kg} / \mathrm{s}\) of dry air, at a dry-bulb temperature of \(30^{\circ} \mathrm{C}\), pressure of \(1 \mathrm{~atm}\), and a humidity of \(0.016 \mathrm{~kg}\) of water/ \(\mathrm{kg}\) of dry air. It leaves the cooling tower saturated with water vapor at \(38^{\circ} \mathrm{C}\).

(a) Calculate the water losses by evaporation in the cooling tower.

(b) To account for water losses in the cooling tower, part of the effluent from a nearby municipal wastewater treatment plant will be used as makeup water. This makeup water contains \(500 \mathrm{mg} / \mathrm{L}\) of dissolved solids. To avoid fouling of the condenser heat-transfer surfaces, the circulating water is to contain no more than \(2000 \mathrm{mg} / \mathrm{L}\) of dissolved solids. Therefore, a small amount of the circulating water must be deliberately discarded (blowdown). Windage losses from the tower are estimated at \(0.2 \%\) of the recirculation rate. Estimate the makeup-water requirement.

Data From Figure 1.13:-

Step by Step Answer: