Question: Facilities layout, identifying value-added activities Consider Exhibit 5-19, which summarizes the activities at the former Bethlehem Steel Corporation's Sparrows Point plant. The blast furnaces make

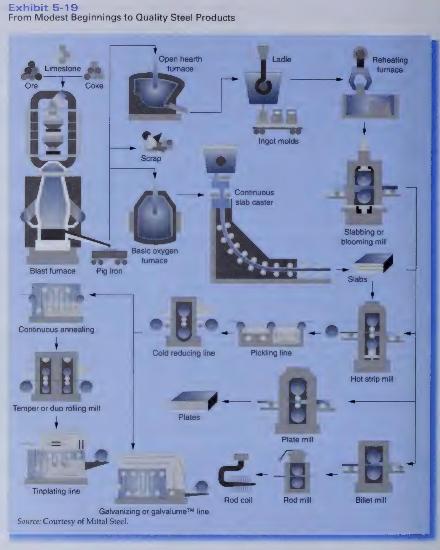

Facilities layout, identifying value-added activities Consider Exhibit 5-19, which summarizes the activities at the former Bethlehem Steel Corporation's Sparrows Point plant. The blast furnaces make the iron that is refined into steel. The basic oxygen furnaces and open-hearth furnaces refine the iron into steel. The mix of iron, scrap, and alloys used to make the steel and the characteristics of the furnace determine the steel's properties, which include formability, strength, toughness, hardenability, and corrosion resistance. The continuous slab caster uses the steel from the basic oxygen furnace to make slabs of steel. The steel from the open-hearth furnace is poured into ingot molds for cooling.

When it has cooled and hardened, the steel ingot, weighing between 11,000 and 80,000 pounds, is removed from the mold and stored. When required, the ingots are reheated and moved to the blooming or slabbing mills, which transform the ingots into blooms (square or rectangular shapes) or slabs (wide and flat shapes), depending on the final product that the ingot will be used to make. This operation also improves the properties of the steel. The billet mill reduces blooms into 4-inch-square billets that are shipped to the rod mill, which produces coils of rod that are then transformed into finished items such as wire. Plates are rolled from reheated slabs in the plate mill. The plates must be cut on all sides to the desired dimensions after rolling. Slabs are also used to make strip steel, which is either made into some final products directly or subjected to finishing operations to make steel sheet or tinplate.

Required

a. What do you think is critical to the customer in making a steel purchasing decision?

b. Do you see any activities in this process that do not add value from the customer's perspective?

c. What performance indicators in this process might be important for the company to monitor?

Exhibit 5-19 From Modest Beginnings to Quality Steel Products Ore Limestone Coke Open hearth tumace Ladie Reheating furnace Scrap Blast furnace Pig Iron Basic oxygen lumace Ingot molds Continuous slab caster Cononucus annealing Cold reducing line Picking line Teraper or dua rating mill Plates 2 Plase mil Slabbing or blooming mil Slabs Hot strip mil Tinplating ine Rod coll Rod mill Biliet mill Galvanizing or galvalume line Source: Courtesy of Maltal Steel.

Step by Step Solution

3.39 Rating (155 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts