Question: Consider the following two-step process: Step A has a processing time of 1 minute per unit, but no setup is required. Step B has a

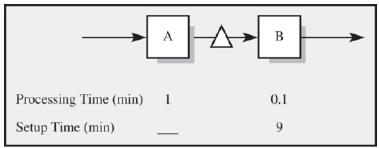

Consider the following two-step process:

Step A has a processing time of 1 minute per unit, but no setup is required. Step B has a processing time of 0.1 minute per unit, but a setup time of 9 minutes is required per batch.

a. What is the capacity of the stamping machine?

b. What batch size would you recommend for the process?

c. Suppose they operate with a production cycle of 1,260 part As and 2,520 part Bs. What would be the average inventory of part A?

a. Suppose units are produced in batches of five (i.e., after each set of 5 units is produced, step B must incur a setup of 9 minutes). What is the capacity of the process (in units per minute)?

b. Suppose they operate with a batch size of 15 and with this batch size step A is the bottleneck. What would be the average inventory after step B?

c. What is the batch size that maximizes the flow rate of this process with minimal inventory? Assume there is ample demand.

A Processing Time (min) 1 Setup Time (min) B 0.1 9

Step by Step Solution

3.41 Rating (160 Votes )

There are 3 Steps involved in it

a Capacity of the Stamping Machine The capacity of the stamping machine depends on the slower of the two steps Step A and Step B Step A has a processi... View full answer

Get step-by-step solutions from verified subject matter experts