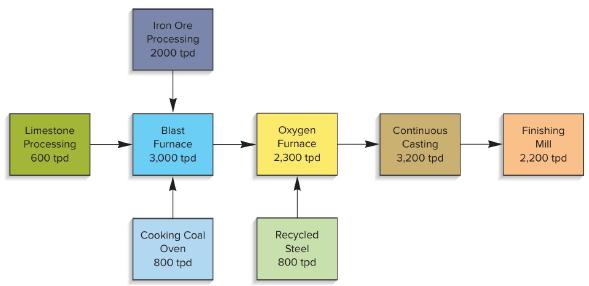

The diagram below represents a simplified version of the steel production process at a steel mill and

Question:

The diagram below represents a simplified version of the steel production process at a steel mill and the capacity of each operation in tonnes per day (tpd). The outputs from iron ore processing, limestone processing, and coking coal oven need to be combined in a ratio of 4: 1 :2 into the blast furnace. Output of blast furnace equals the output of iron ore processing; limestone and coke are only for purifying and burning. The outputs from the blast furnace and recycled steel need to be combined in a ratio of 2: 1 for the oxygen furnace. Output of oxygen furnace = Output of blast furnace + Output of recycled steel. The remaining processes have a ratio of 1: 1 with their downstream process.

a. Calculate the daily capacity of the production process and identify the bottleneck.

b. If the capacity of the bottleneck in part a is increased by 50 percent, what is the new daily capacity and bottleneck?

c. What further improvements are needed to bring plant production to 2,700 tpd?

Step by Step Answer:

Operations Management

ISBN: 9781259270154

6th Canadian Edition

Authors: William J Stevenson, Mehran Hojati, James Cao