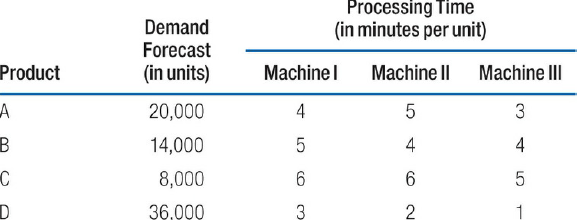

An operations manager, to increase the capacity of his manufacturing plant, decides to buy an additional machine.

Question:

1. Considering only the purchase cost of these machines, which machine, and how many of that machine type should the operations manager buy? Assume the plant operates 8 hours a day and 300 days a year.

2. In addition to the purchase cost of the machines, the operations manager needs to consider the hourly operating cost of these machine, which are given as follows:

Machine I: $12 an hour; Machine II: $14 an hour; and Machine III: $15 an hour.

To satisfy capacity processing requirements and to minimize total purchasing and operating costs, which type of machine, and how many should the operations manager buy?

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Operations Management Managing Global Supply Chains

ISBN: 978-1506302935

1st edition

Authors: Ray R. Venkataraman, Jeffrey K. Pinto

Question Posted: