Custom Molds, Inc., manufactures custom-designed molds for plastic parts and produces custom-made plastic connectors for the electronics

Question:

Custom Molds, Inc., manufactures custom-designed molds for plastic parts and produces custom-made plastic connectors for the electronics industry. Located in Tucson, Arizona, Custom Molds was founded by the father-and-son team of Tom and Mason Miller in 1997. Tom Miller, a mechanical engineer, had more than 20 years of experience in the connector industry with AMP, Inc., a large multinational producer of electronic connectors. Mason Miller graduated from the Arizona State University in 1996 with joint degrees in chemistry and chemical engineering.

The company was originally formed to provide manufacturers of electronic connectors with a source of high-quality, custom-designed molds for producing plastic parts. The market consisted mainly of the product design and development divisions of those manufacturers. Custom Molds worked closely with each customer to design and develop molds to be used in the customer's product development processes. Thus, virtually every mold had to meet exacting standards and was somewhat unique. Orders for multiple molds would arrive when customers moved from the design and pilot-run stage of development to large-scale production of newly designed parts.

As the years went by, Custom Molds's reputation grew as a designer and fabricator of precision molds. Building on this reputation, the Millers decided to expand into the limited manufacture of plastic parts. Ingredient-mixing facilities and injection-molding equipment were added, and by the mid-2000s, Custom Molds developed its reputation to include being a supplier of highquality plastic parts. Because of limited capacity, the company concentrated its sales efforts on supplying parts that were used in limited quantities for research and development efforts and in preproduction pilot runs. Production Processes

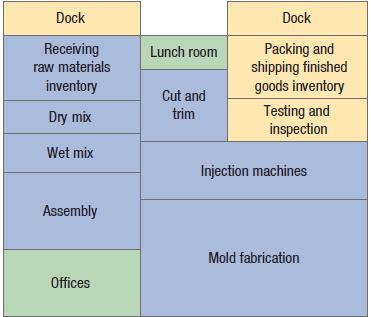

By 2017, operations at Custom Molds involved two distinct processes: one for fabricating molds and one for producing plastic parts. Although different, in many instances these two processes were linked, as when a customer would have Custom Molds both fabricate a mold and produce the necessary parts to support the customer's research and design efforts. All fabrication and production operations were housed in a single facility. The layout was characteristic of a typical job shop, with like processes and similar equipment grouped in various places in the plant. Figure 2.21 shows a layout of the plant floor. Multiple pieces of various types of high-precision machinery, including milling, turning, cutting, and drilling equipment, were located in the mold-fabrication area.

Fabricating molds is a skill-oriented, craftsman-driven process. When an order is received, a design team, comprising a design engineer and 1 of 13 master machinists, reviews the design specifications. Working closely with the customer, the team establishes the final specifications for the mold and gives them to the master machinist for fabrication. It is always the same machinist who was assigned to the design team. At the same time, the purchasing department is given a copy of the design specifications, from which it orders the appropriate raw materials and special tooling. The time needed to receive the ordered materials is usually 3 to 4 weeks. When the materials are received for a particular mold, the plant master scheduler reviews the workload of the assigned master machinist and schedules the mold for fabrication.

Fabricating a mold takes from 2 to 4 weeks, depending on the amount of work the machinist already has scheduled. The fabrication process itself takes only 3 to 5 days. Upon completion, the mold is sent to the testing and inspection area, where it is used to produce a small number of parts on one of the injection-molding machines. If the parts meet the design specifications established by the design team, the mold is passed on to be cleaned and polished. It is then packed and shipped to the customer. One day is spent inspecting and testing the mold and a second day cleaning, polishing, packing, and shipping it to the customer. If the parts made by the mold do

not meet design specifications, the mold is returned to the master machinist for retooling and the process starts over. Currently, Custom Molds has a published lead time of 9 weeks for delivery of custom-fabricated molds.

The manufacturing process for plastic parts is somewhat different from that for mold fabrication. An order for parts may be received in conjunction with an order for a mold to be fabricated. In instances where Custom Molds has previously fabricated the mold and maintains it in inventory, an order may be just for parts. If the mold is already available, the order is reviewed by a design engineer, who verifies the part and raw material specifications.

If the design engineer has any questions concerning the specifications, the customer is contacted and any revisions to specifications are mutually worked out and agreed upon.

Upon acceptance of the part and raw material specifications, raw material orders are placed and production is scheduled for the order. Chemicals and compounds that support plastic-parts manufacturing are typically ordered and received within 1 week. Upon receipt, the compounds are first dry-mixed and blended to achieve the correct composition. Then the mixture is wetmixed to the desired consistency (called slurry) for injection into molding machines. When ready, the slurry is transferred to the injection-molding area by an overhead pipeline and deposited in holding tanks adjacent to the injection machines. The entire mixing process takes only 1 day.

When the slurry is staged and ready, the proper molds are secured- from inventory or from the clean and polish operation if new molds were fabricated for the order-and the parts are manufactured. Although different parts require different temperature and pressure settings, the time to produce a part is relatively constant. Custom Molds has the capacity to produce 5,000 parts per day in the injection-molding department; historically, however, the lead time for handling orders in this department has averaged 1 week. Upon completion of molding, the parts are taken to the cut and trim operation, where they are disconnected and leftover flashing is removed. After being inspected, the parts may be taken to assembly or transferred to the packing and shipping area for shipment to the customer. If assembly of the final parts is not required, the parts can be on their way to the customer 2 days after being molded.

Sometimes, the final product requires some assembly. Typically, this entails attaching metal leads to plastic connectors. If assembly is necessary, an additional 3 days are needed before the order can be shipped. Custom Molds is currently quoting a 3-week lead time for parts not requiring fabricated molds.

QUESTIONS

1. What are the major issues facing Tom and Mason Miller?

2. What are the competitive priorities for Custom Molds’s processes and the changing nature of the industry?

3. What alternatives might the Millers pursue? What key factors should they consider as they evaluate these alternatives?

Step by Step Answer:

Operations Management Processes And Supply Chains

ISBN: 9781292409863

13th Global Edition

Authors: Lee Krajewski, Naresh Malhotra, Larry Ritzman