Marcia Blakely, plant manager at the Newmarket International Manufacturing Company (NIMCO), was preparing for a meeting with

Question:

Marcia Blakely, plant manager at the Newmarket International Manufacturing Company (NIMCO), was preparing for a meeting with her management team. Joining her would be Jack Novak, the company controller; Amy Granger, regional marketing manager; and Joe Barnes, the production manager. The goal of the meeting was to develop a staffing plan for the second quarter. A quick performance review covering the past two quarters proved disappointing. Customer service was poor in spite of higher component inventory levels. Stockouts of some components were a problem and caused production inefficiencies. Nothing seemed to be working smoothly.

Company History

NIMCO was founded by Marcia Blakely when she was only two years out of graduate school. Marcia’s knowledge of mass customization has been the driving force behind NIMCO. The company produces three major custom products.Volume on the products is quite high even though each item is customized specifically for the customer. Each of the products is processed through up to four different work centers. Although each item is unique, the processing time at each work center is constant due to the sophisticated equipment used.

NIMCO currently has 75 full-time employees working in manufacturing. Each employee is scheduled to work 40 hours per week. Because mass customization is used, NIMCO carries no finished goods inventory. The company policy is to meet all demand each period; no back orders or stockouts are permitted.

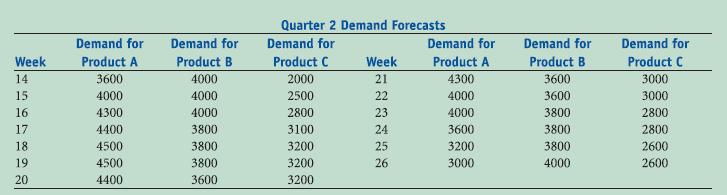

Joe Barnes, the production manager, received the following information in advance of the meeting: demand forecasts for products A, B, and C for each week of the second quarter as shown in the table, and standard labor time estimates for each product. The standard labor times are: product A—0.24 hour, product B—0.38 hour, and product C—0.29 hour.

Joe knew that it would be useful to have you, his assistant, generate additional information for this meeting. You are to convert the individual product forecasts into the total number of labor hours needed each week. For example, in week 14, there are 3600 product A’s multiplied by 0.24 hour, 4000 product B’ times 0.38 hour, and 2000 product C’s times 0.29 hour. The total standard labor time associated with products demanded in period 14 is 2964 hours. After determining the required labor hours each period, Joe wants you to develop three possible staffing plans. The first plan uses a level workforce and does not allow back orders in any period. The second plan uses the original full-time workforce (75 employees) supplemented by the use of overtime to avoid back orders. The third plan adjusts the workforce each period to satisfy all demand by hiring and firing employees. To develop these plans and calculate their associated costs, you need to know that the regular-time wage rate is $14 per hour, overtime is $21 per hour, hiring costs are $500 per employee, and firing costs are $750 per employee.

Your job is to provide analyses of these three plans for Joe to use at the meeting. Make sure to include your recommendation after considering cost, customer service, and operations.

Step by Step Answer: