Timothy L. Hoopman of the 3M Corporation described a novel method for cooling highpowered- density silicon chips

Question:

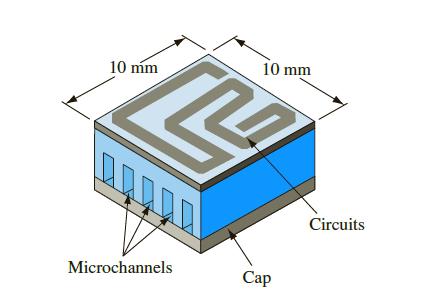

Timothy L. Hoopman of the 3M Corporation described a novel method for cooling highpowered- density silicon chips (D. Cho et al., eds., Microchanneled Structures in DCS, Vol. 19: Microstructures, Sensors, and Actuators, ASME Winter Annual Meeting, Dallas, Texas, November 1990). This method involves etching microchannels in the back surface of the chip. These microchannels typically have hydraulic diameters of 10 mm to 100 mm with length-to-diameter ratios of 50–1000.

Microchannel center-to-center distances can be as small as 100 μm, depending upon geometry. Design a suitable microchannel cooling system for a 10-mm × 10-mm chip. The microetched channels are covered with a silicone cap as shown in the schematic diagram. The chip and cap are to be maintained at a temperature of 350 K and the system has to remove a heat flux of 50 W/cm2. Explain the reason why microchannels, even in laminar flow, produce very high heat transfer coefficients. Also, compare the temperature difference achievable with the microchannel design with a conventional design using water-forced convection cooling in a channel covering the chip surface.

Step by Step Answer:

Principles Of Heat Transfer

ISBN: 9781305387102

8th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn