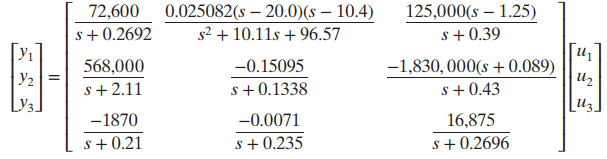

Question: A crystallize is used to separate a pharmaceutical product from the fermentation extract. The three manipulated variables are the fines dissolution rate u 1 ,

(a) Calculate the RGA, and determine the appropriate airings for SISO feedback control. Comment on the role of dynamics in your decision.

(b) Using the IMC tuning rules, design three PI controllers for this process.

(c) Simulate the process response to a step set point, separately, in each of the controlled outputs [use a magnitude of +10% (relative) change]. Next, simulate the response of the system to a simultaneous pair of step changes (again, use a magnitude of +10% relative) in each of the second (purity) and third (product rate) controlled outputs. Try to tune the controller to improve the transient response to the simultaneous step changes.

0.025082(s 20.0)(s 10.4) s2 + 10.11s + 96.57 125,000(s 1.25) s+ 0.39 -1,830, 000(s +0.089) 72,600 s+ 0.2692 -0.15095 568,000 , [U3] | 2 LV3 s+ 2.11 s+0.1338 s+ 0.43 -1870 s+0.21 -0.0071 16,875 s+ 0.235 s + 0.2696 II

Step by Step Solution

3.39 Rating (158 Votes )

There are 3 Steps involved in it

a RGA calculated below RGA 14209 00467 04676 01508 ... View full answer

Get step-by-step solutions from verified subject matter experts