Question: (0) Please use the provided data on available copper alloy materials and toughness estimation. Do not use materials or data that isn't listed in the

(0)

Please use the provided data on available copper alloy materials and toughness estimation. Do not use materials or data that isn't listed in the assignment. I got one expert answer, but it is not calculated with the required data that is provided. Plese help! I would like to see the toughness calculations and the correct units. Thank you!

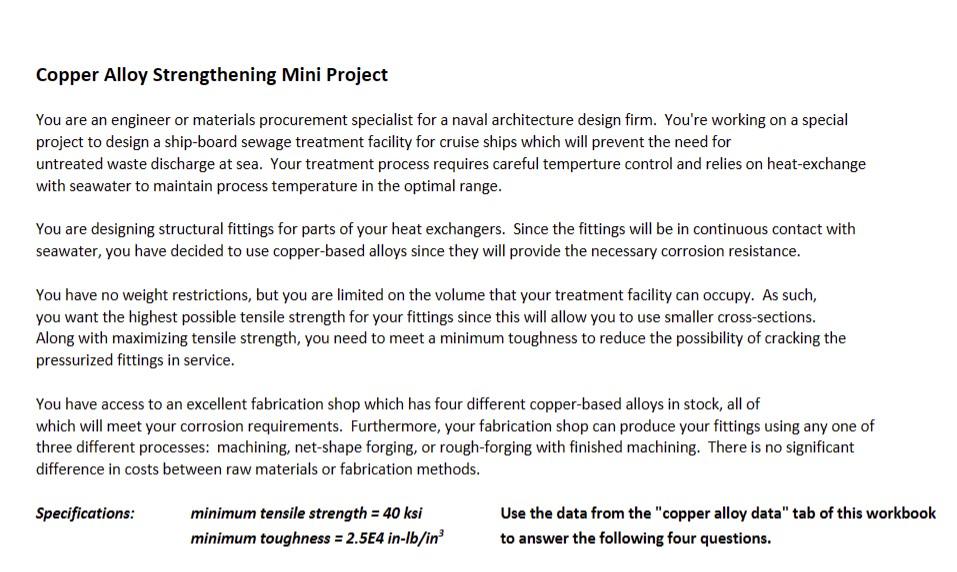

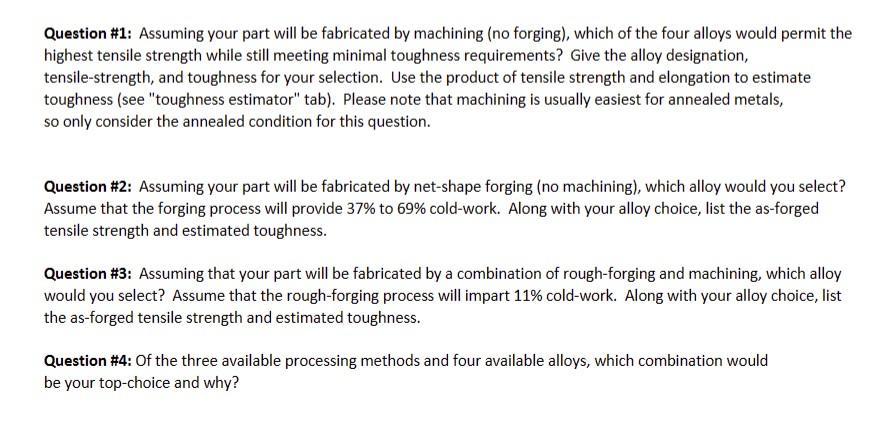

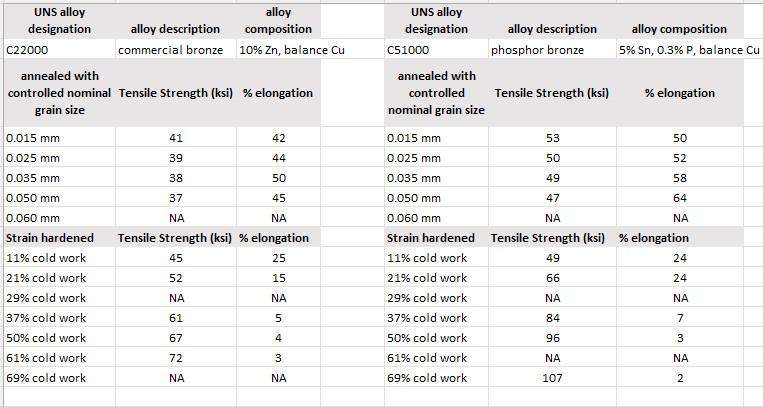

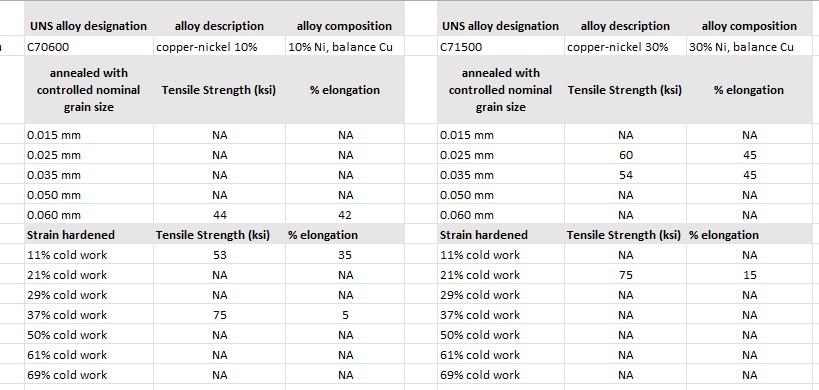

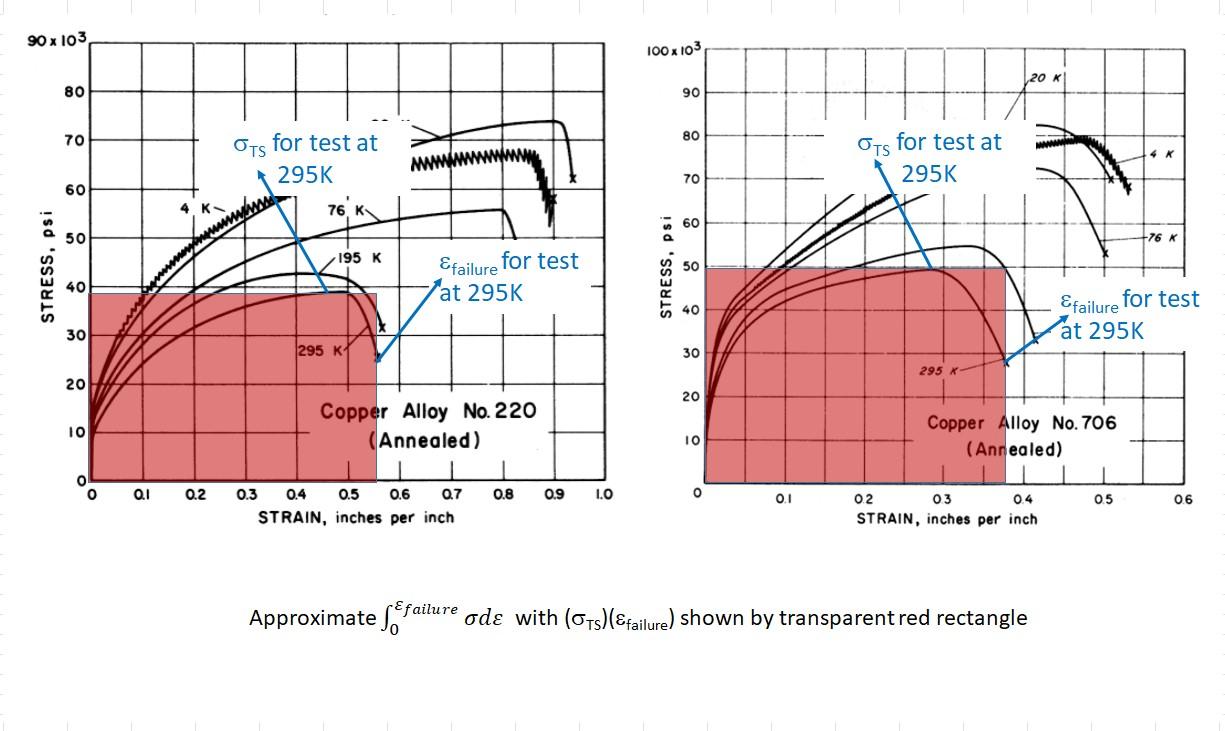

Copper Alloy Strengthening Mini Project You are an engineer or materials procurement specialist for a naval architecture design firm. You're working on a special project to design a ship-board sewage treatment facility for cruise ships which will prevent the need for untreated waste discharge at sea. Your treatment process requires careful temperture control and relies on heat-exchange with seawater to maintain process temperature in the optimal range. You are designing structural fittings for parts of your heat exchangers. Since the fittings will be in continuous contact with seawater, you have decided to use copper-based alloys since they will provide the necessary corrosion resistance. You have no weight restrictions, but you are limited on the volume that your treatment facility can occupy. As such, you want the highest possible tensile strength for your fittings since this will allow you to use smaller cross-sections. Along with maximizing tensile strength, you need to meet a minimum toughness to reduce the possibility of cracking the pressurized fittings in service. You have access to an excellent fabrication shop which has four different copper-based alloys in stock, all of which will meet your corrosion requirements. Furthermore, your fabrication shop can produce your fittings using any one of three different processes: machining, net-shape forging, or rough-forging with finished machining. There is no significant difference in costs between raw materials or fabrication methods. Specifications: minimum tensile strength =40ksi Use the data from the "copper alloy data" tab of this workbe minimum toughness =2.5E4inlb/in3 to answer the following four questions. Question \#1: Assuming your part will be fabricated by machining (no forging), which of the four alloys would permit the highest tensile strength while still meeting minimal toughness requirements? Give the alloy designation, tensile-strength, and toughness for your selection. Use the product of tensile strength and elongation to estimate toughness (see "toughness estimator" tab). Please note that machining is usually easiest for annealed metals, so only consider the annealed condition for this question. Question \#2: Assuming your part will be fabricated by net-shape forging (no machining), which alloy would you select? Assume that the forging process will provide 37% to 69% cold-work. Along with your alloy choice, list the as-forged tensile strength and estimated toughness. Question \#3: Assuming that your part will be fabricated by a combination of rough-forging and machining, which alloy would you select? Assume that the rough-forging process will impart 11% cold-work. Along with your alloy choice, list the as-forged tensile strength and estimated toughness. Approximate 0failured with (TS)(failure) shown by transparent red rectangle

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts