Question: 1. 2. 3. Master Production Schedule which shows the quantities of our end item (a flash drive) that have to be shipped each week: 2

1.

2.

3.

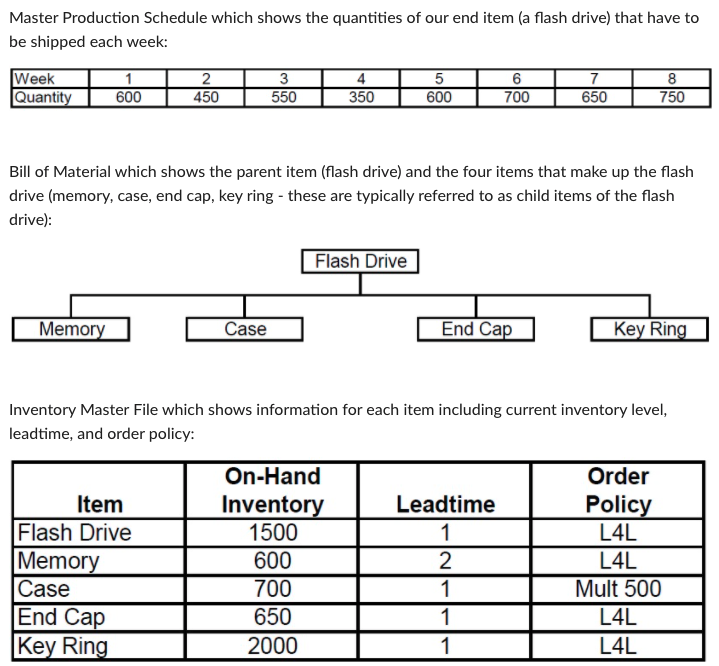

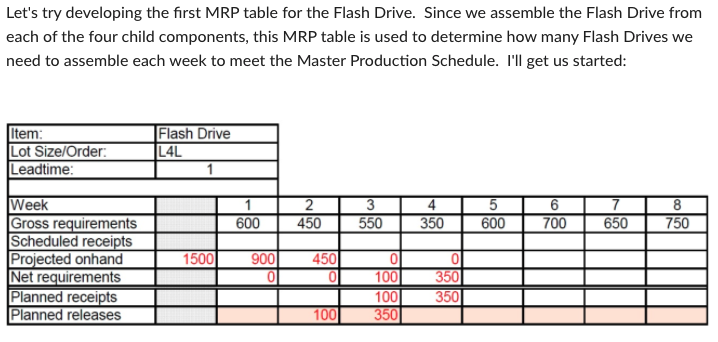

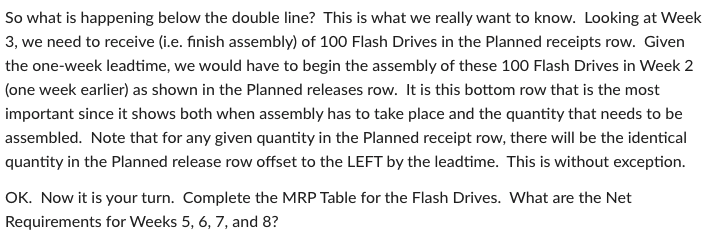

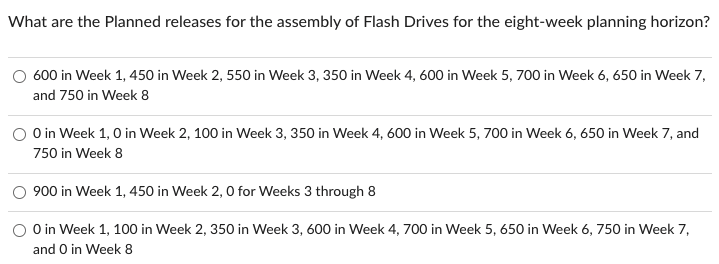

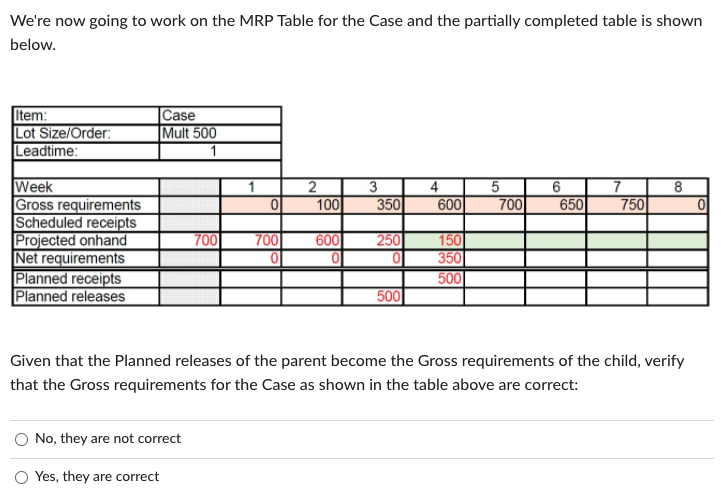

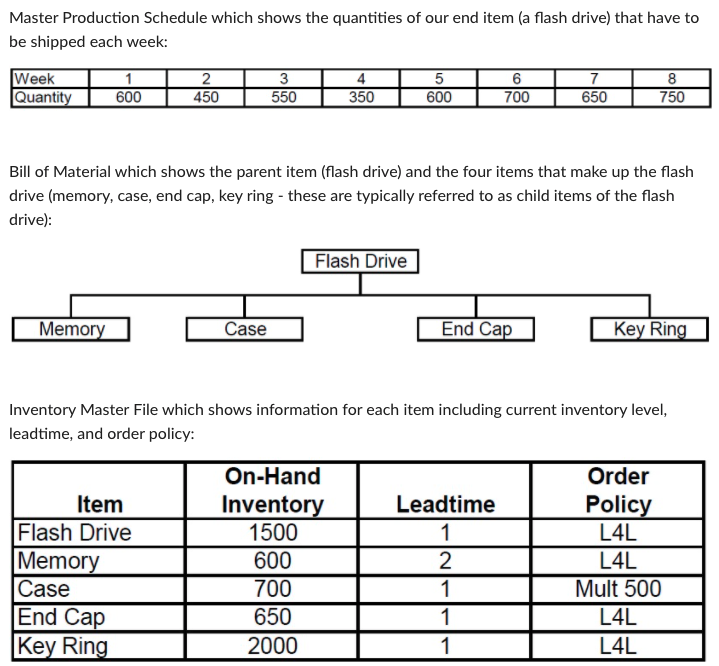

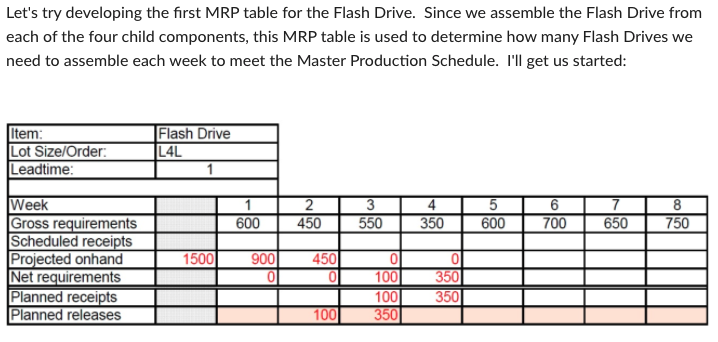

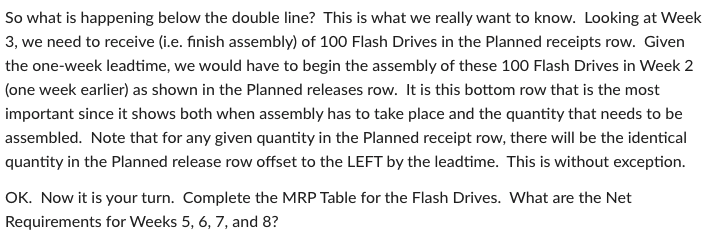

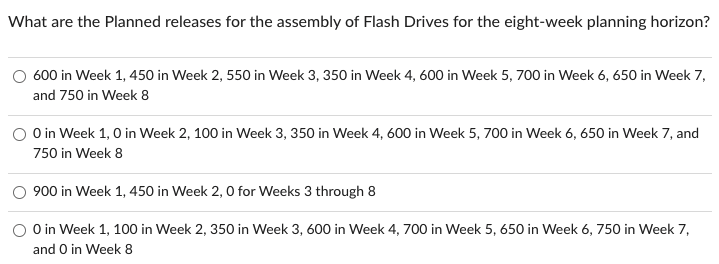

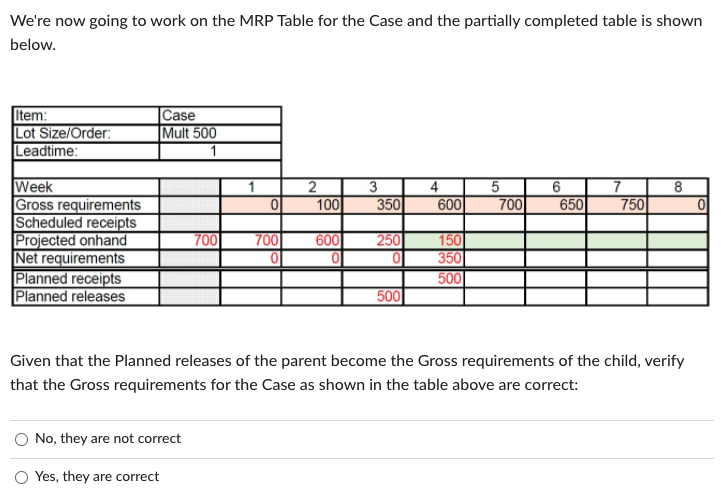

Master Production Schedule which shows the quantities of our end item (a flash drive) that have to be shipped each week: 2 6 8 Week Quantity 1 600 450 3 550 4 350 5 600 700 7 650 750 Bill of Material which shows the parent item (flash drive) and the four items that make up the flash drive (memory, case, end cap, key ring - these are typically referred to as child items of the flash drive): Flash Drive Memory Case End Cap Key Ring Inventory Master File which shows information for each item including current inventory level, leadtime, and order policy: On-Hand Order Item Inventory Leadtime Policy Flash Drive 1500 1 L4L Memory 600 2 L4L Case 700 1 Mult 500 End Cap 650 1 L4L Key Ring 2000 1 L4L Let's try developing the first MRP table for the Flash Drive. Since we assemble the Flash Drive from each of the four child components, this MRP table is used to determine how many Flash Drives we need to assemble each week to meet the Master Production Schedule. I'll get us started: Item: Lot Size/Order: Leadtime: Flash Drive L4L 1 2 450 3 550 4 350 600 5 600 6 700 8 750 650 Week Gross requirements Scheduled receipts Projected onhand Net requirements Planned receipts Planned releases 1500 900 450 0 100 100 350 0 350 350 100 So what is happening below the double line? This is what we really want to know. Looking at Week 3, we need to receive (i.e. finish assembly) of 100 Flash Drives in the Planned receipts row. Given the one week leadtime, we would have to begin the assembly of these 100 Flash Drives in Week 2 (one week earlier) as shown in the planned releases row. It is this bottom row that is the most important since it shows both when assembly has to take place and the quantity that needs to be assembled. Note that for any given quantity in the Planned receipt row, there will be the identical quantity in the Planned release row offset to the LEFT by the leadtime. This is without exception. OK. Now it is your turn. Complete the MRP Table for the Flash Drives. What are the Net Requirements for Weeks 5, 6, 7, and 8? What are the planned releases for the assembly of Flash Drives for the eight-week planning horizon? 600 in Week 1, 450 in Week 2,550 in Week 3, 350 in Week 4, 600 in Week 5, 700 in Week 6, 650 in Week 7, and 750 in Week 8 O in Week 1, 0 in Week 2, 100 in Week 3, 350 in Week 4, 600 in Week 5, 700 in Week 6, 650 in Week 7, and 750 in Week 8 900 in Week 1, 450 in Week 2,0 for Weeks 3 through 8 O in Week 1, 100 in Week 2, 350 in Week 3, 600 in Week 4, 700 in Week 5, 650 in Week 6, 750 in Week 7, and O in Week 8 We're now going to work on the MRP Table for the Case and the partially completed table is shown below. Case Item: Lot Size/Order: Leadtime: Mult 500 1 1 2 100 8 3 350 4 6001 5 700 6 650 7 750 Week Gross requirements Scheduled receipts Projected onhand Net requirements Planned receipts Planned releases 7001 7001 6001 250 1501 350 500 500 Given that the Planned releases of the parent become the Gross requirements of the child, verify that the Gross requirements for the Case as shown in the table above are correct: No, they are not correct Yes, they are correct