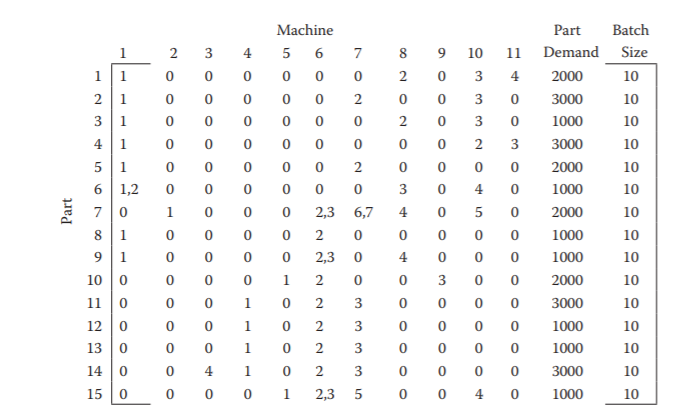

Question: 1 2 4 Machine 5 6 0 0 8 10 3 0 11 7 0 0 5 0 0 0 2 9 0 0 3

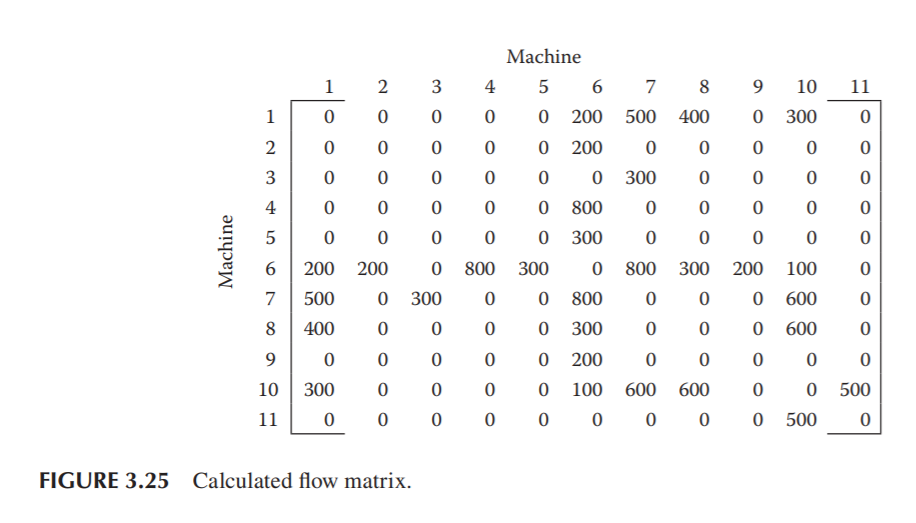

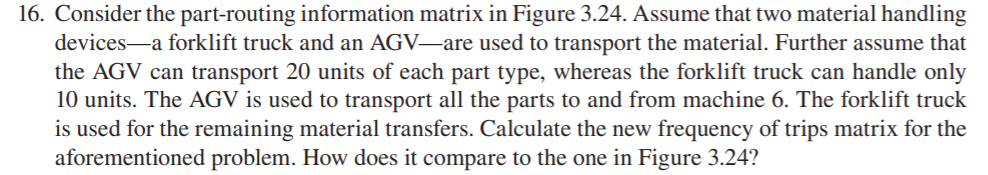

1 2 4 Machine 5 6 0 0 8 10 3 0 11 7 0 0 5 0 0 0 2 9 0 0 3 4 0 0 0 0 0 2 0 0 0 0 0 0 0 0 3 3 2 2 0 0 0 0 0 0 0 0 0 3 0 0 0 0 0 0 0 0 0 2 0 0 0 0 0 0 3 0 4 0 Part 7 1 0 0 0 2,3 6,7 4 0 5 0 11 21 31 41 51 6 1,2 7 0 8 1 91 100 110 120 130 14 0 15 0 Part Demand 2000 3000 1000 3000 2000 1000 2000 1000 1000 2000 3000 1000 1000 3000 1000 Batch Size 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 0 0 0 0 0 0 0 0 0 0 0 0 0 2 2,3 2 0 4 0 0 0 0 0 0 1 2. 0 0 3 0 0 0 0 1 0 2 3 0 0 0 0 0 0 1 0 2 0 0 0 0 0 0 1 0 2 3 0 0 0 0 0 4 1 0 2 3 0 0 0 0 0 0 0 1 2,3 5 0 0 4 0 1 2 3 Machine 4 5 6 0 0 200 10 11 8 9 400 0 1 0 o 7 500 0 0 300 O 2 0 0 0 0 0 200 0 0 0 0 3 0 0 0 0 0 0 0 0 0 0 300 0 0 0 0 0 0 800 0 0 4 5 0 0 0 0 0 0 0 0 0 300 0 0 0 Machine 6 200 200 0 800 300 0 800 300 200 100 0 7 500 0 300 0 0 800 0 0 0 600 0 8 400 0 0 0 0 300 0 0 0 600 0 9 0 0 0 0 0 200 0 0 0 0 0 0 10 300 0 0 0 0 600 600 500 100 0 0 500 11 0 0 0 0 0 0 0 0 0 FIGURE 3.25 Calculated flow matrix. 16. Consider the part-routing information matrix in Figure 3.24. Assume that two material handling devicesa forklift truck and an AGVare used to transport the material. Further assume that the AGV can transport 20 units of each part type, whereas the forklift truck can handle only 10 units. The AGV is used to transport all the parts to and from machine 6. The forklift truck is used for the remaining material transfers. Calculate the new frequency of trips matrix for the aforementioned problem. How does it compare to the one in Figure 3.24? 1 2 4 Machine 5 6 0 0 8 10 3 0 11 7 0 0 5 0 0 0 2 9 0 0 3 4 0 0 0 0 0 2 0 0 0 0 0 0 0 0 3 3 2 2 0 0 0 0 0 0 0 0 0 3 0 0 0 0 0 0 0 0 0 2 0 0 0 0 0 0 3 0 4 0 Part 7 1 0 0 0 2,3 6,7 4 0 5 0 11 21 31 41 51 6 1,2 7 0 8 1 91 100 110 120 130 14 0 15 0 Part Demand 2000 3000 1000 3000 2000 1000 2000 1000 1000 2000 3000 1000 1000 3000 1000 Batch Size 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 0 0 0 0 0 0 0 0 0 0 0 0 0 2 2,3 2 0 4 0 0 0 0 0 0 1 2. 0 0 3 0 0 0 0 1 0 2 3 0 0 0 0 0 0 1 0 2 0 0 0 0 0 0 1 0 2 3 0 0 0 0 0 4 1 0 2 3 0 0 0 0 0 0 0 1 2,3 5 0 0 4 0 1 2 3 Machine 4 5 6 0 0 200 10 11 8 9 400 0 1 0 o 7 500 0 0 300 O 2 0 0 0 0 0 200 0 0 0 0 3 0 0 0 0 0 0 0 0 0 0 300 0 0 0 0 0 0 800 0 0 4 5 0 0 0 0 0 0 0 0 0 300 0 0 0 Machine 6 200 200 0 800 300 0 800 300 200 100 0 7 500 0 300 0 0 800 0 0 0 600 0 8 400 0 0 0 0 300 0 0 0 600 0 9 0 0 0 0 0 200 0 0 0 0 0 0 10 300 0 0 0 0 600 600 500 100 0 0 500 11 0 0 0 0 0 0 0 0 0 FIGURE 3.25 Calculated flow matrix. 16. Consider the part-routing information matrix in Figure 3.24. Assume that two material handling devicesa forklift truck and an AGVare used to transport the material. Further assume that the AGV can transport 20 units of each part type, whereas the forklift truck can handle only 10 units. The AGV is used to transport all the parts to and from machine 6. The forklift truck is used for the remaining material transfers. Calculate the new frequency of trips matrix for the aforementioned problem. How does it compare to the one in Figure 3.24

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts