Question: 1. A final assembly plant for a certain automobile model is to have a capacity of 50,000 units annually. The plant will operate 50

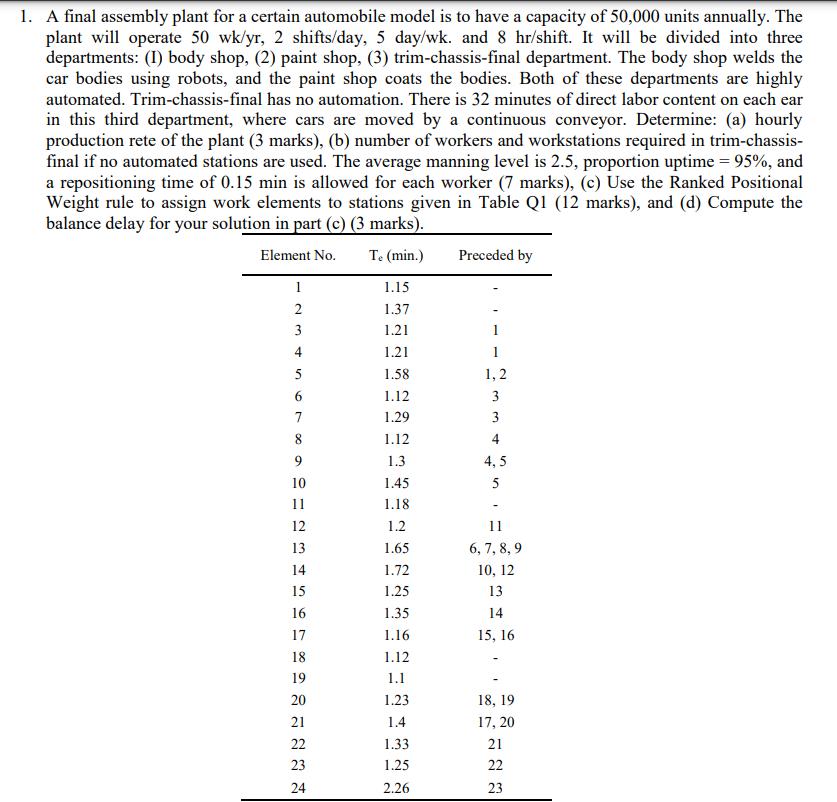

1. A final assembly plant for a certain automobile model is to have a capacity of 50,000 units annually. The plant will operate 50 wk/yr, 2 shifts/day, 5 day/wk. and 8 hr/shift. It will be divided into three departments: (I) body shop, (2) paint shop, (3) trim-chassis-final department. The body shop welds the car bodies using robots, and the paint shop coats the bodies. Both of these departments are highly automated. Trim-chassis-final has no automation. There is 32 minutes of direct labor content on each ear in this third department, where cars are moved by a continuous conveyor. Determine: (a) hourly production rete of the plant (3 marks), (b) number of workers and workstations required in trim-chassis- final if no automated stations are used. The average manning level is 2.5, proportion uptime = 95%, and a repositioning time of 0.15 min is allowed for each worker (7 marks), (c) Use the Ranked Positional Weight rule to assign work elements to stations given in Table Q1 (12 marks), and (d) Compute the balance delay for your solution in part (c) (3 marks). Element No. Te (min.) 1 2 4 10 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 1.15 1.37 1.21 1.21 1.58 1.12 1.29 1.12 1.3 1.45 1.18 1.2 1.65 1.72 1.25 1.35 1.16 1.12 1.1 1.23 1.4 1.33 1.25 2.26 Preceded by 1 1 1,2 3 3 4 4,5 5 11 6,7,8,9 10, 12 13 14 15, 16 18, 19 17, 20 21 22 23

Step by Step Solution

There are 3 Steps involved in it

1 a Hourly production rate of the plant Plant operates 50 weeksyear 2 shiftsday 5 daysweek So total ... View full answer

Get step-by-step solutions from verified subject matter experts