Question: 1. Brainstorm at least two locations in your team's process where heat exchangers will be needed. Direct heaters could count as long as there is

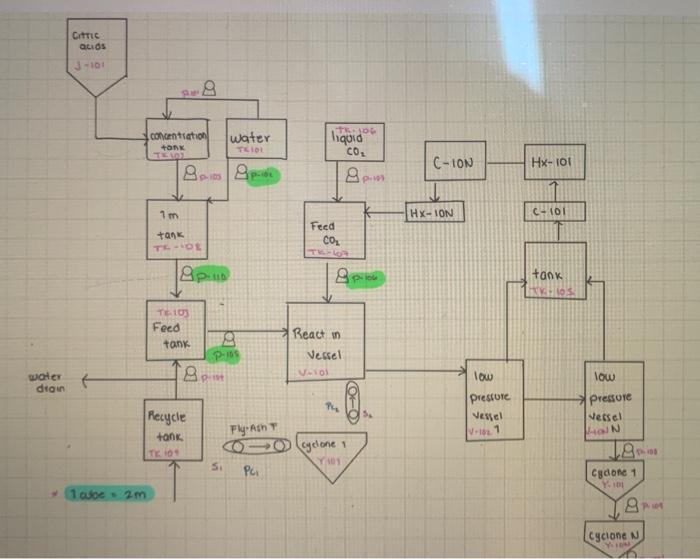

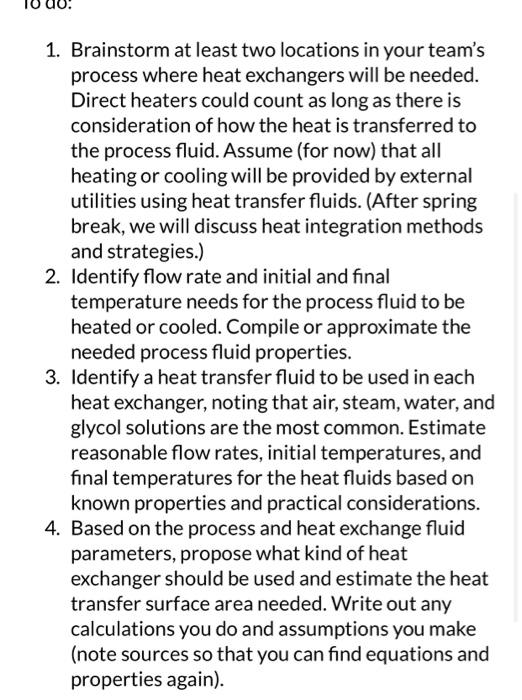

1. Brainstorm at least two locations in your team's process where heat exchangers will be needed. Direct heaters could count as long as there is consideration of how the heat is transferred to the process fluid. Assume (for now) that all heating or cooling will be provided by external utilities using heat transfer fluids. (After spring break, we will discuss heat integration methods and strategies.) 2. Identify flow rate and initial and final temperature needs for the process fluid to be heated or cooled. Compile or approximate the needed process fluid properties. 3. Identify a heat transfer fluid to be used in each heat exchanger, noting that air, steam, water, and glycol solutions are the most common. Estimate reasonable flow rates, initial temperatures, and final temperatures for the heat fluids based on known properties and practical considerations. 4. Based on the process and heat exchange fluid parameters, propose what kind of heat exchanger should be used and estimate the heat transfer surface area needed. Write out any calculations you do and assumptions you make (note sources so that you can find equations and properties again). 1. Descriptions of the two (or more) heat exchangers that your team will need. Include the type of heat exchanger, the process fluid to be heated or cooled, the heat exchange fluid, and the material(s) of construction. 2. Scans of heat exchanger calculations including fluid properties and assumptions

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts