Question: 1. Differentiate between absolute positioning and incremental positioning. (3 marks) 2. Implementing and technology may have positives and negatives associated with it. What are three

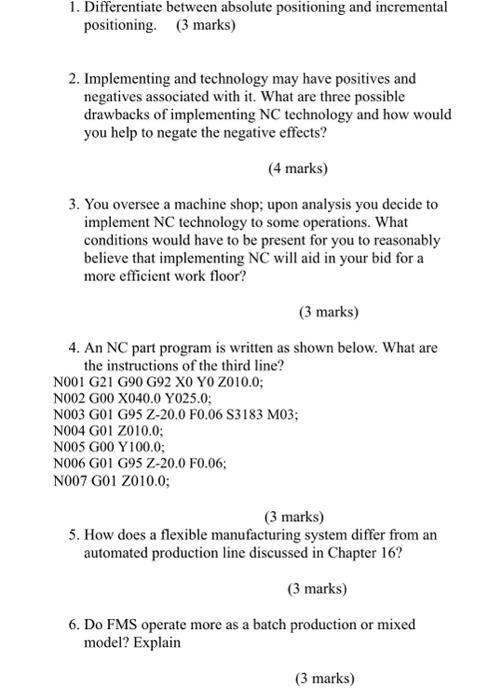

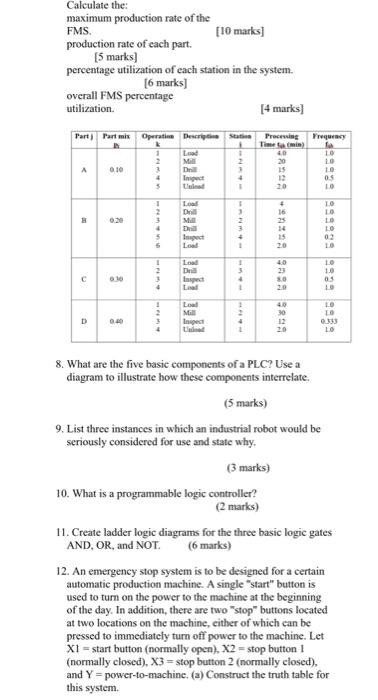

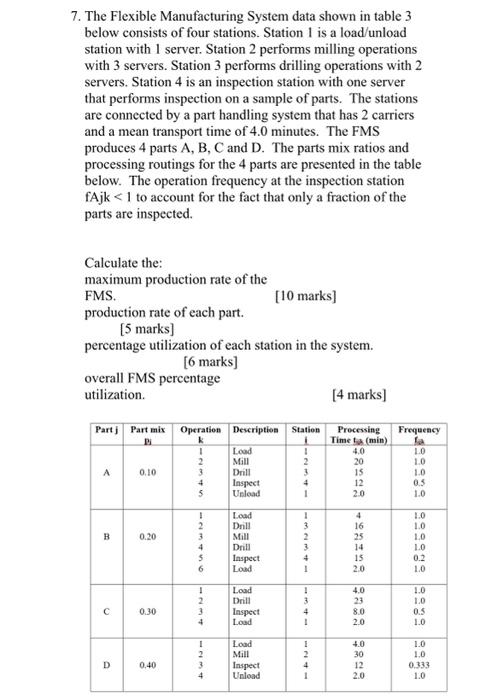

1. Differentiate between absolute positioning and incremental positioning. (3 marks) 2. Implementing and technology may have positives and negatives associated with it. What are three possible drawbacks of implementing NC technology and how would you help to negate the negative effects? (4 marks) 3. You oversee a machine shop; upon analysis you decide to implement NC technology to some operations. What conditions would have to be present for you to reasonably believe that implementing NC will aid in your bid for a more efficient work floor? (3marks) 4. An NC part program is written as shown below. What are the instructions of the third line? N001 G21 G90 G92 X0 Y0 Z010.0; N002 G00 X040.0 Y025.0; N003 G01 G95 Z-20.0 F0.06 S3183 M03; N004 G01 Z010.0; N005 G00 Y100.0; N006 G01 G95 Z-20.0 F0.06; N007 G01 Z010.0; (3 marks) 5. How does a flexible manufacturing system differ from an automated production line discussed in Chapter 16 ? (3 marks) 6. Do FMS operate more as a batch production or mixed model? Explain (3 marks) Calculate the: maximum production rate of the FMS. [10 marks] production rate of each part. [5 marks] percentage utilization of each station in the system. [6 marks] overall FMS percentage utilization. [4 marks] 8. What are the five basic components of a PLC? Use a diagram to illustrate how these components interrelate. (5marks) 9. List three instances in which an industrial robot would be seriously considered for use and state why. (3 marks) 10. What is a programmable logic controller? (2 narks) 11. Create ladder logic diagrams for the three basic logic gates AND, OR, and NOT. (6 marks) 12. An emergency stop system is to be designed for a certain automatic production machine. A single "start" button is used to tum on the power to the machine at the beginning of the day. In addition, there are two "stop" buttons located at two locations on the machine, cither of which can be pressed to immediately turn off power to the machine. Let X1= start button (normally open), X2= stop button 1 (normally closed), X3= stop button 2 (normally closed), and Y= power-to-machine, (a) Construct the truth table for this system. 7. The Flexible Manufacturing System data shown in table 3 below consists of four stations. Station 1 is a load/unload station with 1 server. Station 2 performs milling operations with 3 servers. Station 3 performs drilling operations with 2 servers. Station 4 is an inspection station with one server that performs inspection on a sample of parts. The stations are connected by a part handling system that has 2 carriers and a mean transport time of 4.0 minutes. The FMS produces 4 parts A, B, C and D. The parts mix ratios and processing routings for the 4 parts are presented in the table below. The operation frequency at the inspection station fAjk

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts