Question: 1. Executive Summary: In the Executive Summary you may include a short INTODUCTION on the Case Study, the PURPOSE of analyzing the Case Study, the

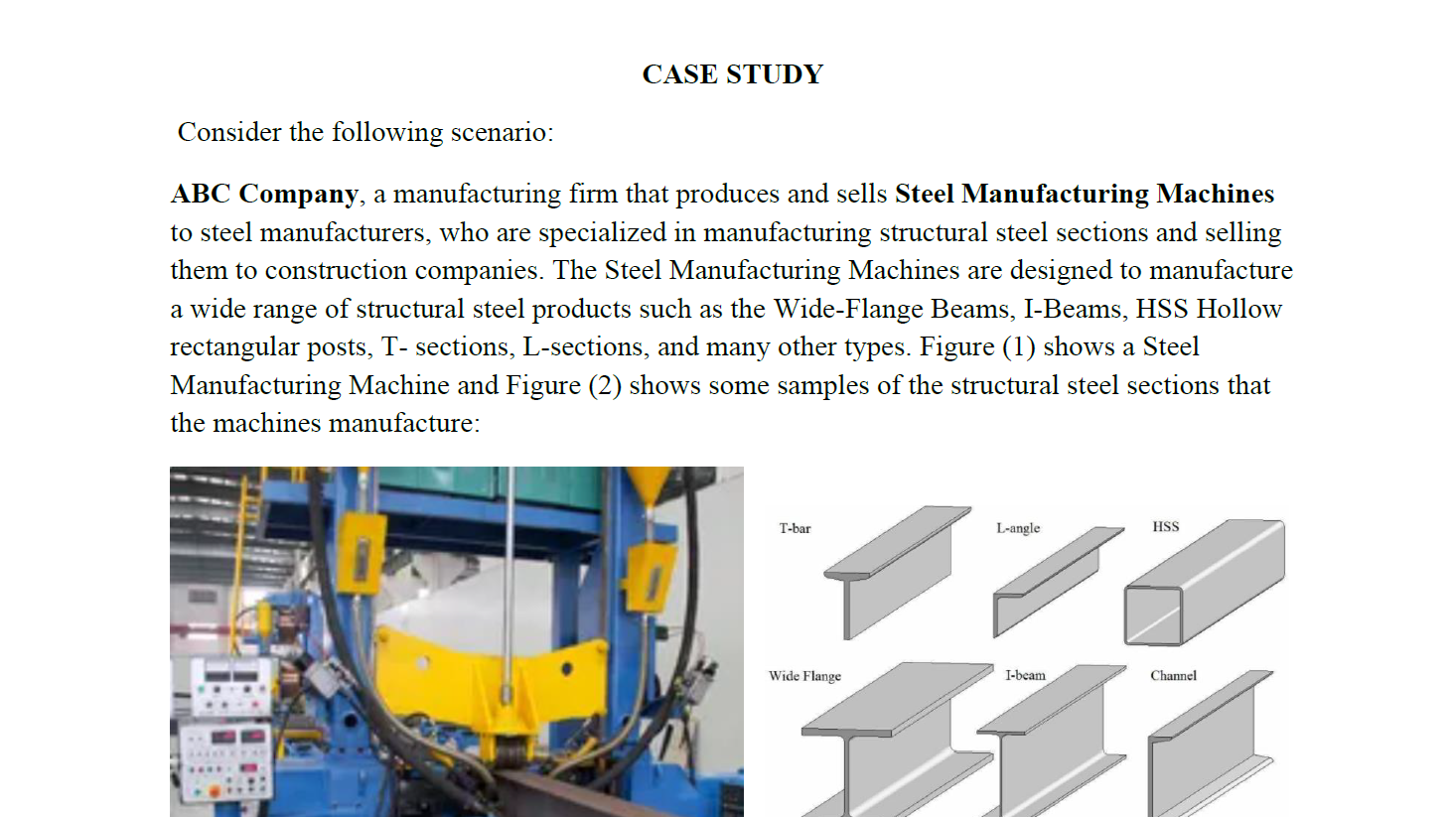

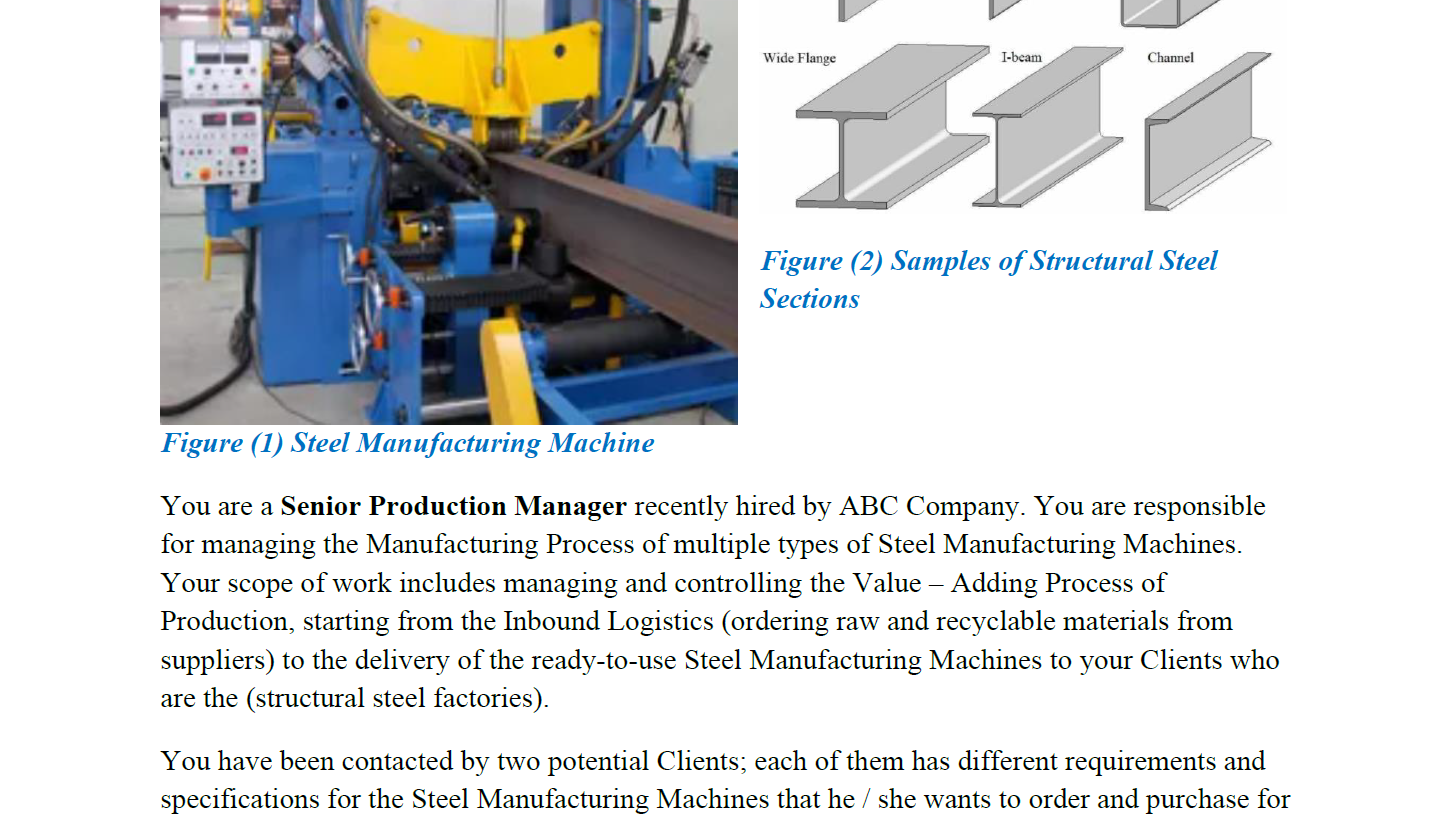

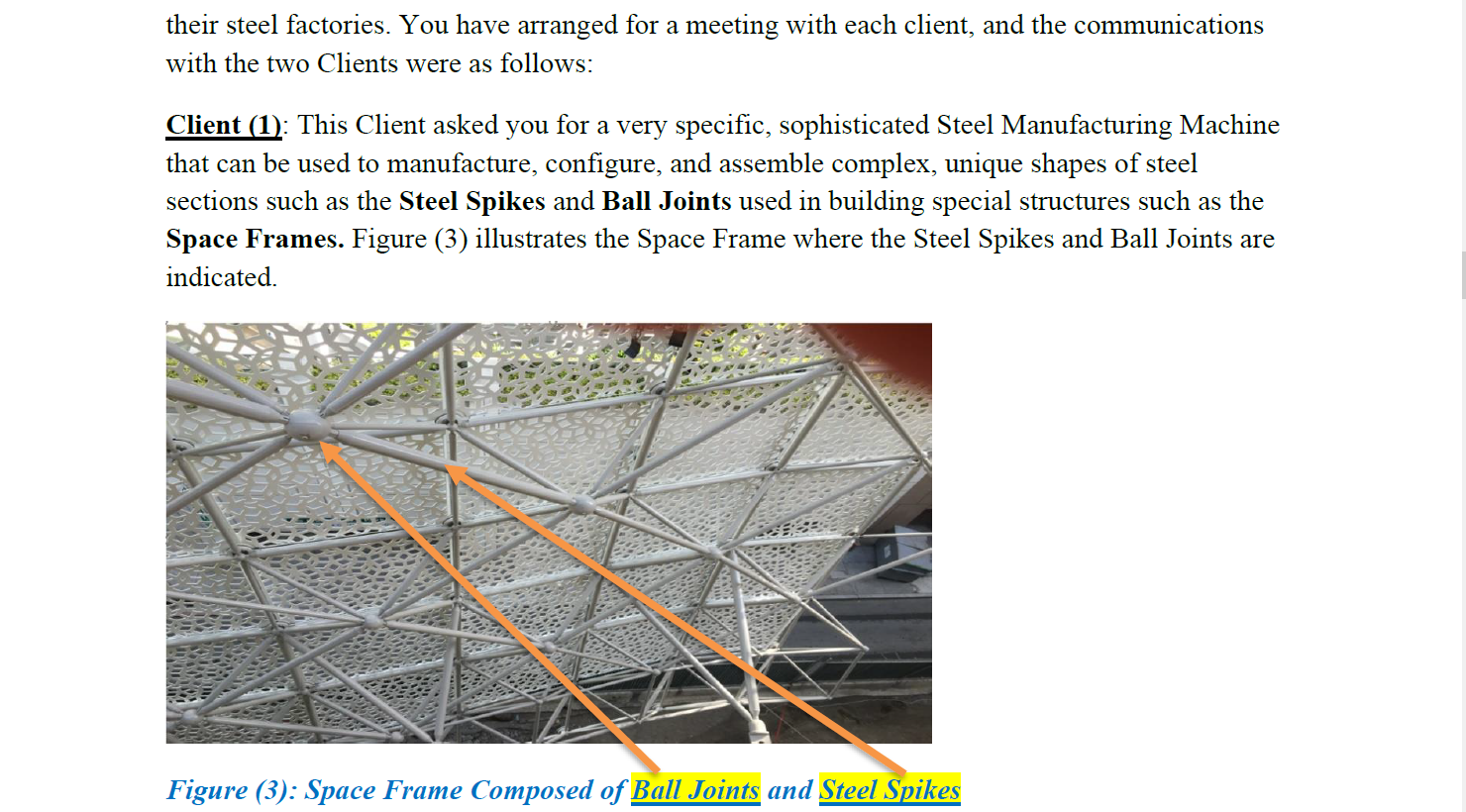

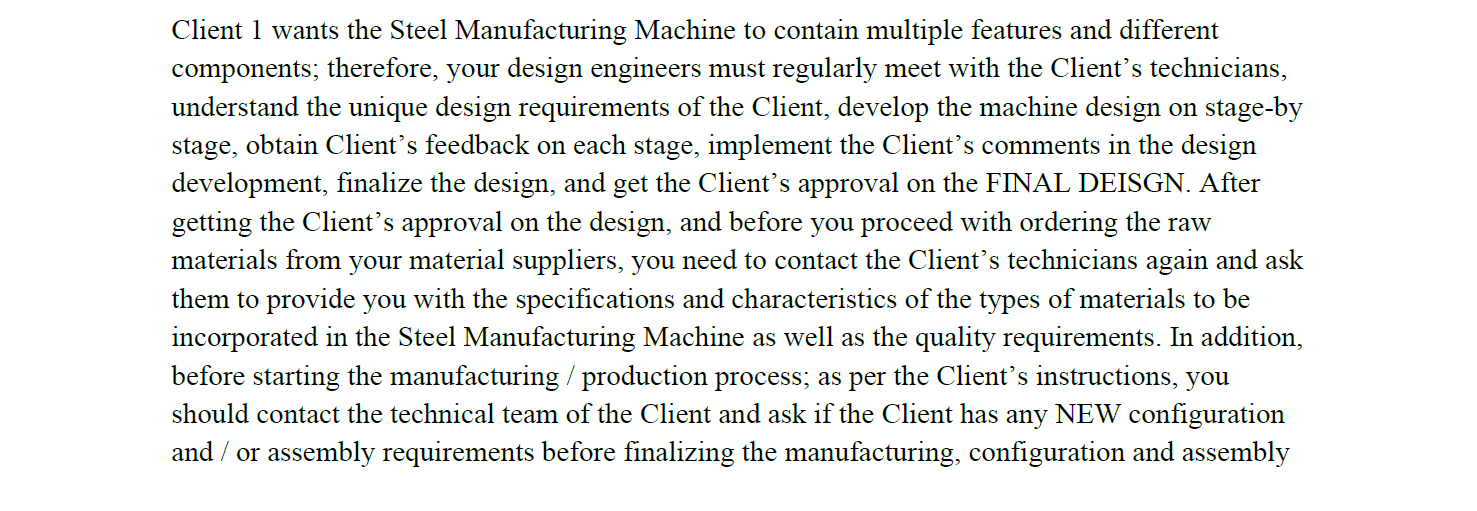

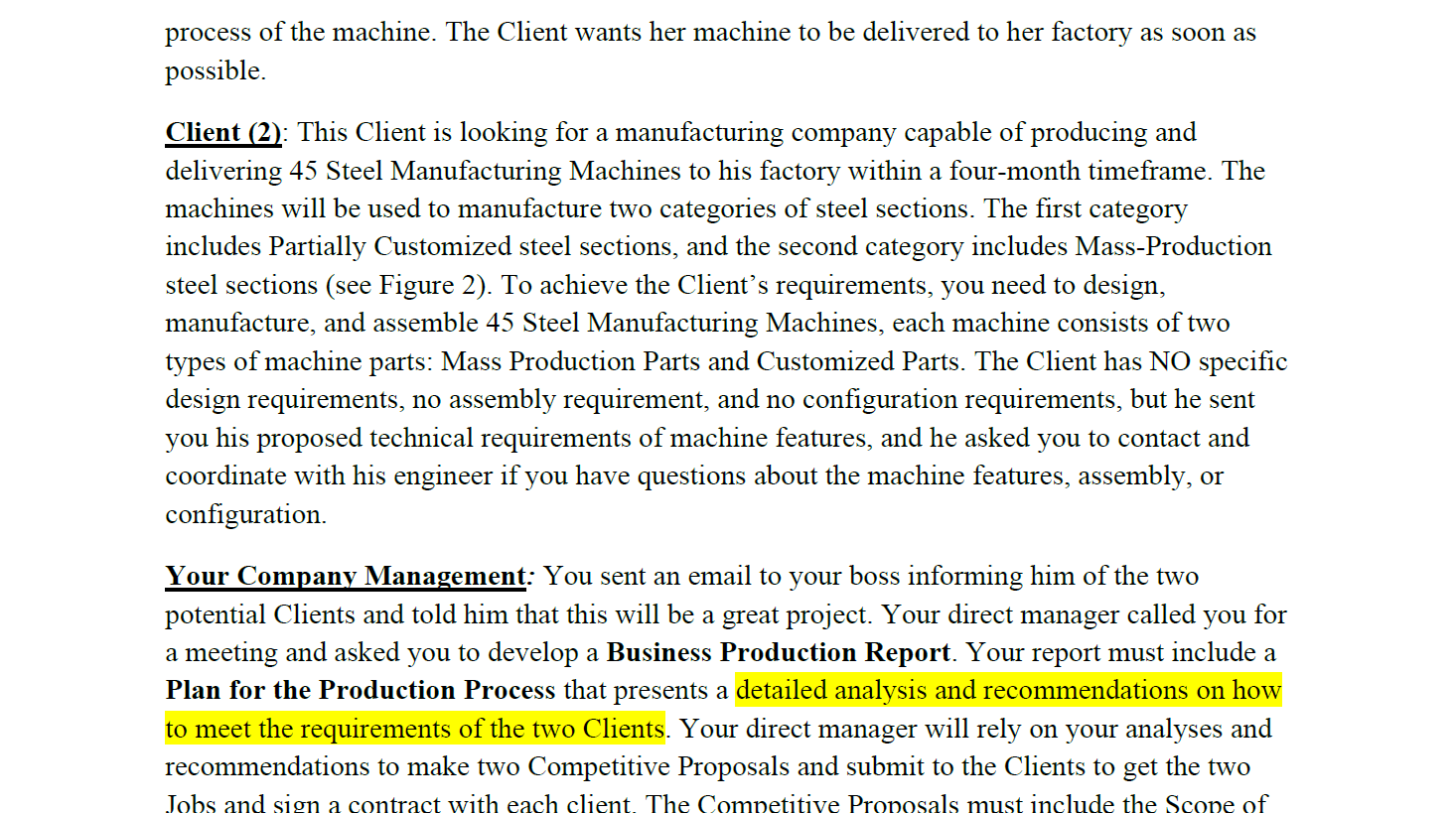

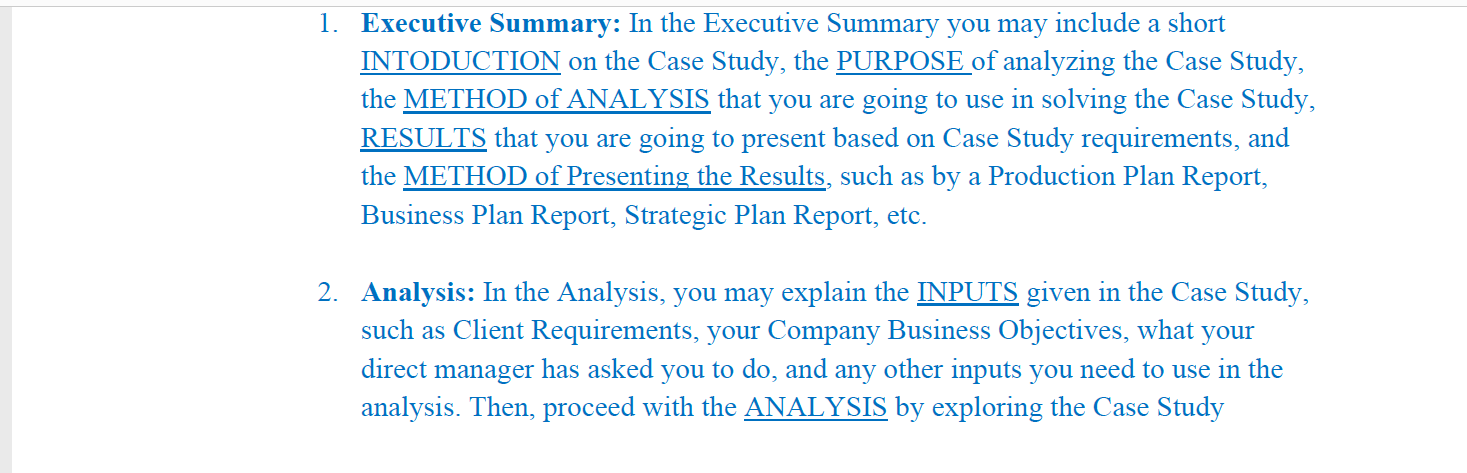

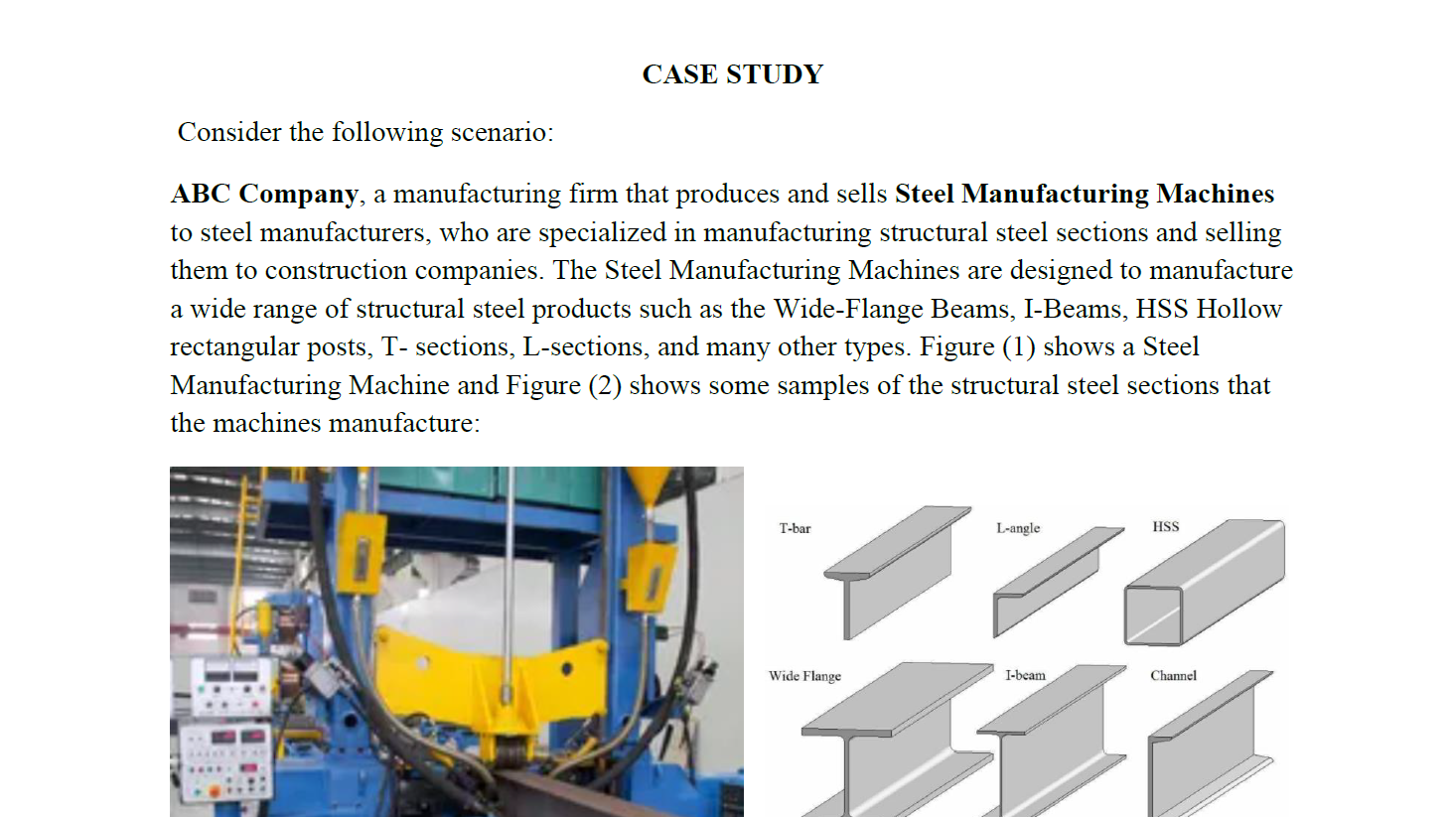

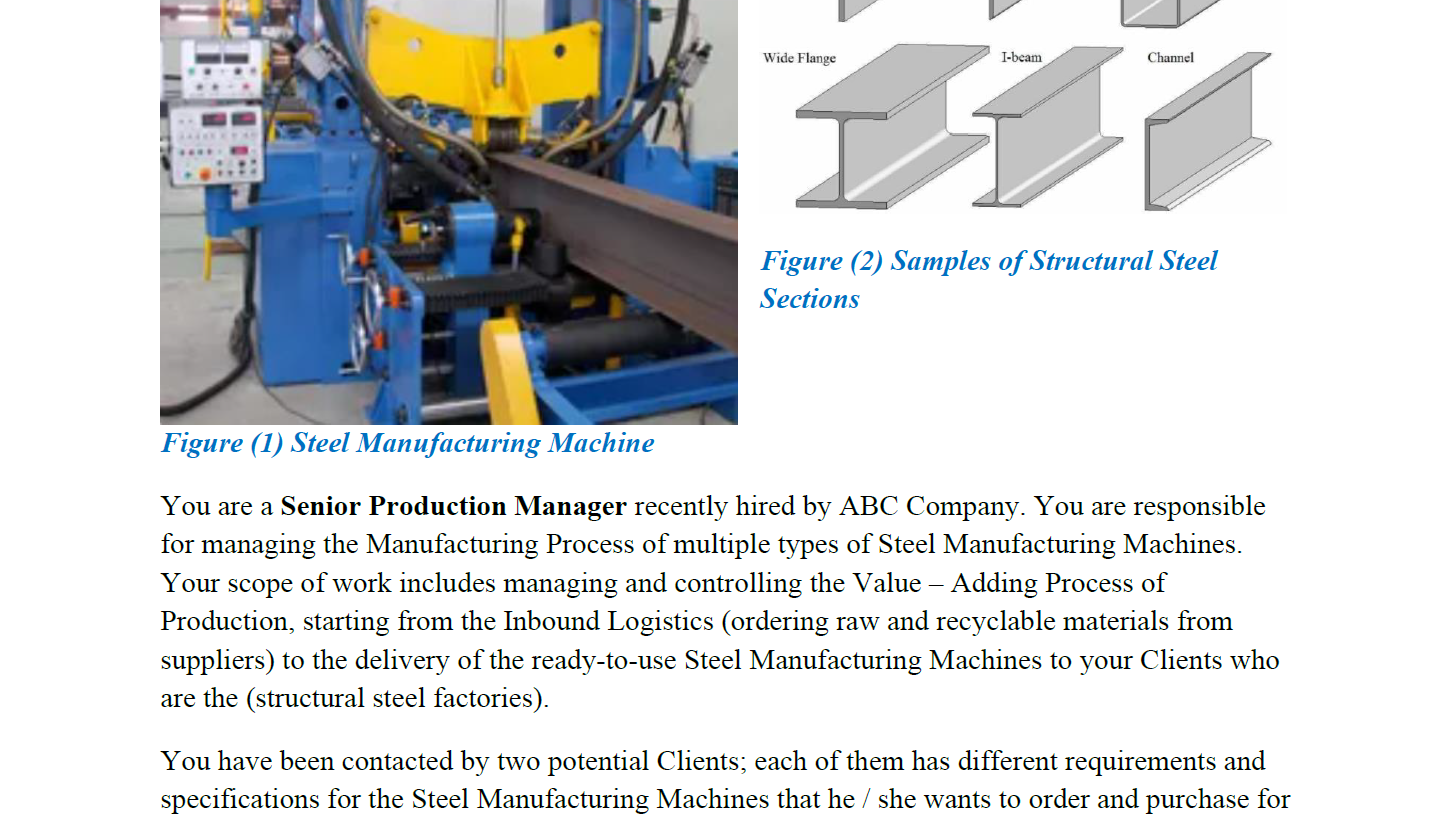

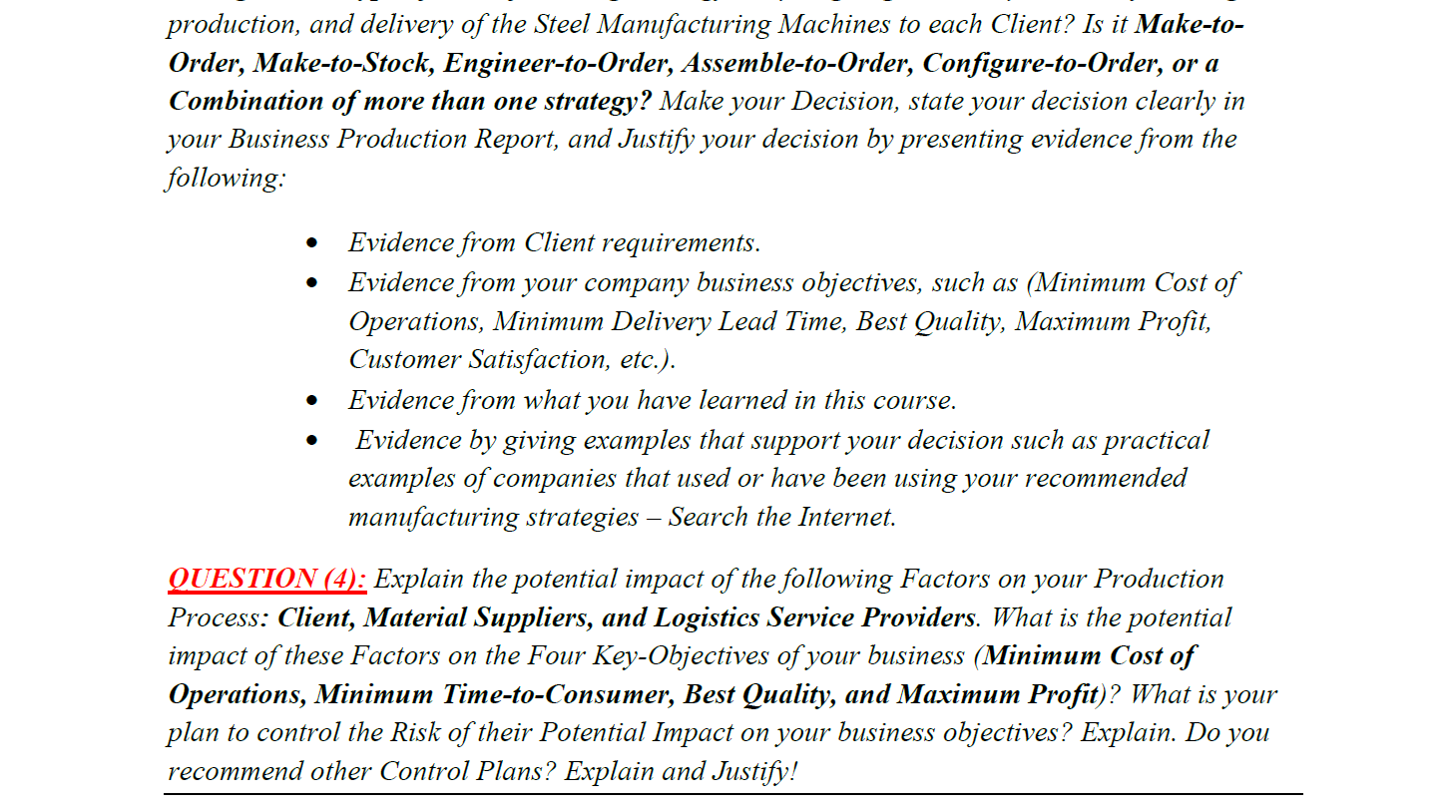

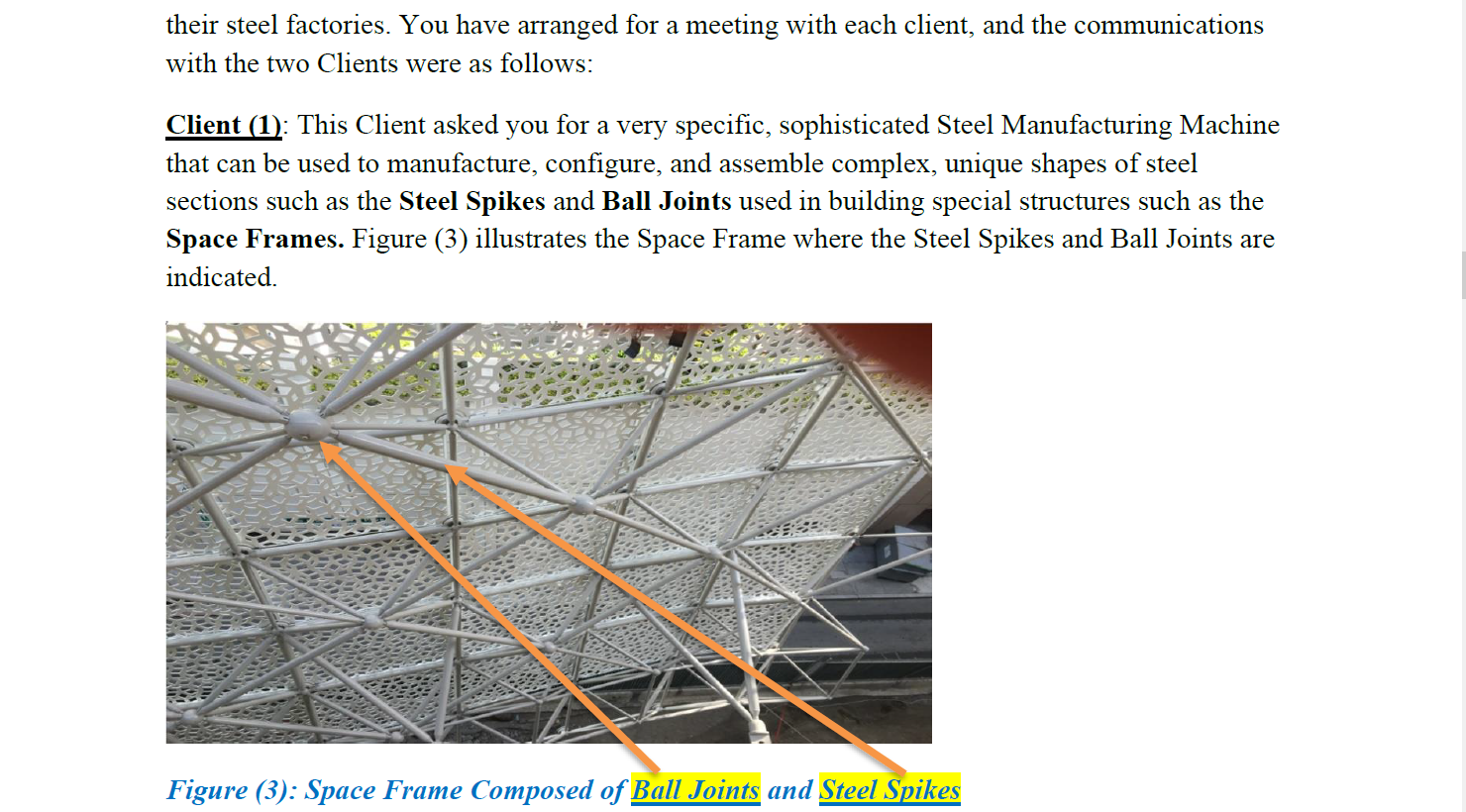

1. Executive Summary: In the Executive Summary you may include a short INTODUCTION on the Case Study, the PURPOSE of analyzing the Case Study, the METHOD of ANALYSIS that you are going to use in solving the Case Study, RESULTS that you are going to present based on Case Study requirements, and the METHOD of Presenting the Results, such as by a Production Plan Report, Business Plan Report, Strategic Plan Report, etc. 2. Analysis: In the Analysis, you may explain the INPUTS given in the Case Study, such as Client Requirements, your Company Business Objectives, what your direct manager has asked you to do, and any other inputs you need to use in the analysis. Then, proceed with the ANALYSIS by exploring the Case Study Requirements given in the questions Q1, Q2, Q3, etc, and reply in-details with a precise, clear, thematically organized, and justified analysis 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. Remember that in practical life as a Senior Manager, you will be responsible for your business decisions and recommendations to your company, because you are directing your employer to invest money, time, and other resources in what you recommend. You are putting your company reputation at the edge; therefore, your recommended solutions and business decisions must be well studied, justified, and convincing. 4. Conclusion: In the conclusion, you will summarize your work in a one short paragraph: Summarize the general guidelines and requirements of the Case Study, your analysis, results, recommendations, and business decisions. CASE STUDY Consider the following scenario: ABC Company, a manufacturing firm that produces and sells Steel Manufacturing Machines to steel manufacturers, who are specialized in manufacturing structural steel sections and selling them to construction companies. The Steel Manufacturing Machines are designed to manufacture a wide range of structural steel products such as the Wide-Flange Beams, I-Beams, HSS Hollow rectangular posts, T- sections, L-sections, and many other types. Figure (1) shows a Steel Manufacturing Machine and Figure (2) shows some samples of the structural steel sections that the machines manufacture: T-bar L-angle HSS Wide Flange I-beam Channel 12 Wide Flange 1-beam Channel I Figure (2) Samples of Structural Steel Sections Figure (1) Steel Manufacturing Machine You are a Senior Production Manager recently hired by ABC Company. You are responsible for managing the Manufacturing Process of multiple types of Steel Manufacturing Machines. Your scope of work includes managing and controlling the Value Adding Process of Production, starting from the Inbound Logistics (ordering raw and recyclable materials from suppliers) to the delivery of the ready-to-use Steel Manufacturing Machines to your Clients who are the (structural steel factories). You have been contacted by two potential Clients; each of them has different requirements and specifications for the Steel Manufacturing Machines that he / she wants to order and purchase for production, and delivery of the Steel Manufacturing Machines to each Client? Is it Make-to- Order, Make-to-Stock, Engineer-to-Order, Assemble-to-Order, Configure-to-Order, or a Combination of more than one strategy? Make your Decision, state your decision clearly in your Business Production Report, and Justify your decision by presenting evidence from the following: Evidence from Client requirements. Evidence from your company business objectives, such as (Minimum Cost of Operations, Minimum Delivery Lead Time, Best Quality, Maximum Profit, Customer Satisfaction, etc.). Evidence from what you have learned in this course. Evidence by giving examples that support your decision such as practical examples of companies that used or have been using your recommended manufacturing strategies Search the Internet. QUESTION (4): Explain the potential impact of the following Factors on your Production Process: Client, Material Suppliers, and Logistics Service Providers. What is the potential impact of these Factors on the Four Key-Objectives of your business (Minimum Cost of Operations, Minimum Time-to-Consumer, Best Quality, and Maximum Profit)? What is your plan to control the Risk of their Potential Impact on your business objectives? Explain. Do you recommend other Control Plans? Explain and Justify! their steel factories. You have arranged for a meeting with each client, and the communications with the two Clients were as follows: Client (1): This Client asked you for a very specific, sophisticated Steel Manufacturing Machine that can be used to manufacture, configure, and assemble complex, unique shapes of steel sections such as the Steel Spikes and Ball Joints used in building special structures such as the Space Frames. Figure (3) illustrates the Space Frame where the Steel Spikes and Ball Joints are indicated. Figure (3): Space Frame Composed of Ball Joints and Steel Spikes Client I wants the Steel Manufacturing Machine to contain multiple features and different components; therefore, your design engineers must regularly meet with the Client's technicians, understand the unique design requirements of the Client, develop the machine design on stage-by stage, obtain Client's feedback on each stage, implement the Client's comments in the design development, finalize the design, and get the Client's approval on the FINAL DEISGN. After getting the Client's approval on the design, and before you proceed with ordering the raw materials from your material suppliers, you need to contact the Client's technicians again and ask them to provide you with the specifications and characteristics of the types of materials to be incorporated in the Steel Manufacturing Machine as well as the quality requirements. In addition, before starting the manufacturing/production process; as per the Client's instructions, you should contact the technical team of the Client and ask if the Client has any NEW configuration and / or assembly requirements before finalizing the manufacturing, configuration and assembly process of the machine. The Client wants her machine to be delivered to her factory as soon as possible. Client (2): This Client is looking for a manufacturing company capable of producing and delivering 45 Steel Manufacturing Machines to his factory within a four-month timeframe. The machines will be used to manufacture two categories of steel sections. The first category includes Partially Customized steel sections, and the second category includes Mass-Production steel sections (see Figure 2). To achieve the Client's requirements, you need to design, manufacture, and assemble 45 Steel Manufacturing Machines, each machine consists of two types of machine parts: Mass Production Parts and Customized Parts. The Client has NO specific design requirements, no assembly requirement, and no configuration requirements, but he sent you his proposed technical requirements of machine features, and he asked you to contact and coordinate with his engineer if you have questions about the machine features, assembly, or configuration. Your Company Management: You sent an email to your boss informing him of the two potential Clients and told him that this will be a great project. Your direct manager called you for a meeting and asked you to develop a Business Production Report. Your report must include a Plan for the Production Process that presents a detailed analysis and recommendations on how to meet the requirements of the two Clients. Your direct manager will rely on your analyses and recommendations to make two Competitive Proposals and submit to the Clients to get the two Jobs and sign a contract with each client. The Competitive Proposals must include the Scope of QUESTION (3): Based on your analysis of Clients' requirements, as a Senior Production Manager, what type of Manufacturing Strategy are you going to use in your manufacturing, production, and delivery of the Steel Manufacturing Machines to each Client? Is it Make-to- Order, Make-to-Stock, Engineer-to-Order, Assemble-to-Order, Configure-to-Order, or a Combination of more than one strategy? Make your Decision, state your decision clearly in your Business Production Report, and Justify your decision by presenting evidence from the following: Evidence from Client requirements. Evidence from your company business objectives, such as (Minimum Cost of Operations, Minimum Delivery Lead Time, Best Quality, Maximum Profit, Customer Satisfaction, etc.). Evidence from what you have learned in this course. Evidence by giving examples that support your decision such as practical examples of companies that used or have been using your recommended manufacturing strategies Search the Internet. QUESTION (4): Explain the potential impact of the following Factors on your Production Process: Client, Material Suppliers, and Logistics Service Providers. What is the potential impact of these Factors on the Four Key-Objectives of your business (Minimum Cost of Operations, Minimum Time-to-Consumer, Best Quality, and Maximum Profit)? What is your 1 +12 Dial of the ni.. Datestial aisa 1. Executive Summary: In the Executive Summary you may include a short INTODUCTION on the Case Study, the PURPOSE of analyzing the Case Study, the METHOD of ANALYSIS that you are going to use in solving the Case Study, RESULTS that you are going to present based on Case Study requirements, and the METHOD of Presenting the Results, such as by a Production Plan Report, Business Plan Report, Strategic Plan Report, etc. 2. Analysis: In the Analysis, you may explain the INPUTS given in the Case Study, such as Client Requirements, your Company Business Objectives, what your direct manager has asked you to do, and any other inputs you need to use in the analysis. Then, proceed with the ANALYSIS by exploring the Case Study Requirements given in the questions Q1, Q2, Q3, etc, and reply in-details with a precise, clear, thematically organized, and justified analysis 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. Remember that in practical life as a Senior Manager, you will be responsible for your business decisions and recommendations to your company, because you are directing your employer to invest money, time, and other resources in what you recommend. You are putting your company reputation at the edge; therefore, your recommended solutions and business decisions must be well studied, justified, and convincing. 4. Conclusion: In the conclusion, you will summarize your work in a one short paragraph: Summarize the general guidelines and requirements of the Case Study, your analysis, results, recommendations, and business decisions. CASE STUDY Consider the following scenario: ABC Company, a manufacturing firm that produces and sells Steel Manufacturing Machines to steel manufacturers, who are specialized in manufacturing structural steel sections and selling them to construction companies. The Steel Manufacturing Machines are designed to manufacture a wide range of structural steel products such as the Wide-Flange Beams, I-Beams, HSS Hollow rectangular posts, T- sections, L-sections, and many other types. Figure (1) shows a Steel Manufacturing Machine and Figure (2) shows some samples of the structural steel sections that the machines manufacture: T-bar L-angle HSS Wide Flange I-beam Channel 12 Wide Flange 1-beam Channel I Figure (2) Samples of Structural Steel Sections Figure (1) Steel Manufacturing Machine You are a Senior Production Manager recently hired by ABC Company. You are responsible for managing the Manufacturing Process of multiple types of Steel Manufacturing Machines. Your scope of work includes managing and controlling the Value Adding Process of Production, starting from the Inbound Logistics (ordering raw and recyclable materials from suppliers) to the delivery of the ready-to-use Steel Manufacturing Machines to your Clients who are the (structural steel factories). You have been contacted by two potential Clients; each of them has different requirements and specifications for the Steel Manufacturing Machines that he / she wants to order and purchase for production, and delivery of the Steel Manufacturing Machines to each Client? Is it Make-to- Order, Make-to-Stock, Engineer-to-Order, Assemble-to-Order, Configure-to-Order, or a Combination of more than one strategy? Make your Decision, state your decision clearly in your Business Production Report, and Justify your decision by presenting evidence from the following: Evidence from Client requirements. Evidence from your company business objectives, such as (Minimum Cost of Operations, Minimum Delivery Lead Time, Best Quality, Maximum Profit, Customer Satisfaction, etc.). Evidence from what you have learned in this course. Evidence by giving examples that support your decision such as practical examples of companies that used or have been using your recommended manufacturing strategies Search the Internet. QUESTION (4): Explain the potential impact of the following Factors on your Production Process: Client, Material Suppliers, and Logistics Service Providers. What is the potential impact of these Factors on the Four Key-Objectives of your business (Minimum Cost of Operations, Minimum Time-to-Consumer, Best Quality, and Maximum Profit)? What is your plan to control the Risk of their Potential Impact on your business objectives? Explain. Do you recommend other Control Plans? Explain and Justify! their steel factories. You have arranged for a meeting with each client, and the communications with the two Clients were as follows: Client (1): This Client asked you for a very specific, sophisticated Steel Manufacturing Machine that can be used to manufacture, configure, and assemble complex, unique shapes of steel sections such as the Steel Spikes and Ball Joints used in building special structures such as the Space Frames. Figure (3) illustrates the Space Frame where the Steel Spikes and Ball Joints are indicated. Figure (3): Space Frame Composed of Ball Joints and Steel Spikes Client I wants the Steel Manufacturing Machine to contain multiple features and different components; therefore, your design engineers must regularly meet with the Client's technicians, understand the unique design requirements of the Client, develop the machine design on stage-by stage, obtain Client's feedback on each stage, implement the Client's comments in the design development, finalize the design, and get the Client's approval on the FINAL DEISGN. After getting the Client's approval on the design, and before you proceed with ordering the raw materials from your material suppliers, you need to contact the Client's technicians again and ask them to provide you with the specifications and characteristics of the types of materials to be incorporated in the Steel Manufacturing Machine as well as the quality requirements. In addition, before starting the manufacturing/production process; as per the Client's instructions, you should contact the technical team of the Client and ask if the Client has any NEW configuration and / or assembly requirements before finalizing the manufacturing, configuration and assembly process of the machine. The Client wants her machine to be delivered to her factory as soon as possible. Client (2): This Client is looking for a manufacturing company capable of producing and delivering 45 Steel Manufacturing Machines to his factory within a four-month timeframe. The machines will be used to manufacture two categories of steel sections. The first category includes Partially Customized steel sections, and the second category includes Mass-Production steel sections (see Figure 2). To achieve the Client's requirements, you need to design, manufacture, and assemble 45 Steel Manufacturing Machines, each machine consists of two types of machine parts: Mass Production Parts and Customized Parts. The Client has NO specific design requirements, no assembly requirement, and no configuration requirements, but he sent you his proposed technical requirements of machine features, and he asked you to contact and coordinate with his engineer if you have questions about the machine features, assembly, or configuration. Your Company Management: You sent an email to your boss informing him of the two potential Clients and told him that this will be a great project. Your direct manager called you for a meeting and asked you to develop a Business Production Report. Your report must include a Plan for the Production Process that presents a detailed analysis and recommendations on how to meet the requirements of the two Clients. Your direct manager will rely on your analyses and recommendations to make two Competitive Proposals and submit to the Clients to get the two Jobs and sign a contract with each client. The Competitive Proposals must include the Scope of QUESTION (3): Based on your analysis of Clients' requirements, as a Senior Production Manager, what type of Manufacturing Strategy are you going to use in your manufacturing, production, and delivery of the Steel Manufacturing Machines to each Client? Is it Make-to- Order, Make-to-Stock, Engineer-to-Order, Assemble-to-Order, Configure-to-Order, or a Combination of more than one strategy? Make your Decision, state your decision clearly in your Business Production Report, and Justify your decision by presenting evidence from the following: Evidence from Client requirements. Evidence from your company business objectives, such as (Minimum Cost of Operations, Minimum Delivery Lead Time, Best Quality, Maximum Profit, Customer Satisfaction, etc.). Evidence from what you have learned in this course. Evidence by giving examples that support your decision such as practical examples of companies that used or have been using your recommended manufacturing strategies Search the Internet. QUESTION (4): Explain the potential impact of the following Factors on your Production Process: Client, Material Suppliers, and Logistics Service Providers. What is the potential impact of these Factors on the Four Key-Objectives of your business (Minimum Cost of Operations, Minimum Time-to-Consumer, Best Quality, and Maximum Profit)? What is your 1 +12 Dial of the ni.. Datestial aisa