Question: 1-) Find mathematical model formulation 2-) Solver model construction CoffeelsLife, Inc., one of the world's famous French Press coffee maker producers, is founded in 1995

1-) Find mathematical model formulation

2-) Solver model construction

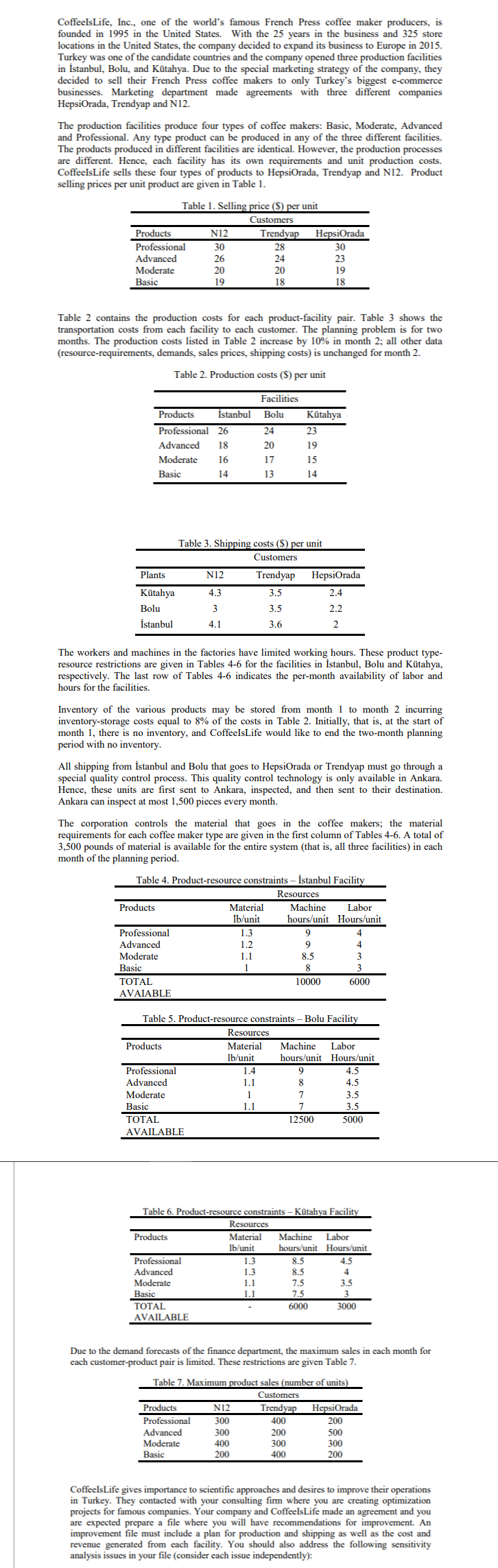

CoffeelsLife, Inc., one of the world's famous French Press coffee maker producers, is founded in 1995 in the United States. With the 25 years in the business and 325 store locations in the United States, the company decided to expand its business to Europe in 2015. Turkey was one of the candidate countries and the company opened three production facilities in stanbul, Bolu, and Ktahya. Due to the special marketing strategy of the company, they decided to sell their French Press coffee makers to only Turkey's biggest e-commerce businesses. Marketing department made agreements with three different companies HepsiOrada, Trendyap and N12. The production facilities produce four types of coffee makers: Basic, Moderate, Advanced and Professional. Any type product can be produced in any of the three different facilities. The products produced in different facilities are identical. However, the production processes are different. Hence, each facility has its own requirements and unit production costs. CoffeelsLife sells these four types of products to HepsiOrada, Trendyap and N12. Product selling prices per unit product are given in Table 1. Table 1. Selling price (S) per unit Customers Products N12 Trendyap HepsiOrada Professional 30 28 30 Advanced 26 24 23 Moderate 20 20 19 Basic 19 18 18 contains the production costs for each product-facility pair. shows the transportation costs from each facility to each customer. The planning problem is for two months. The production costs listed in Table 2 increase by 10% in month 2; all other data (resource-requirements, demands, sales prices, shipping costs) is unchanged for month 2. Table 2. Production costs (S) per unit Facilities Bolu Products stanbul Professional 26 Advanced 18 Moderate 16 Basic 14 24 20 17 13 Ktahya 23 19 15 14 Table 3. Shipping costs ($) per unit Customers Plants N12 Trendyap HepsiOrada Ktahya 4.3 3.5 2.4 Bolu 3 3.5 2.2 stanbul 4.1 3.6 2 The workers and machines in the factories have limited working hours. These product type- resource restrictions are given in Tables 4-6 for the facilities in stanbul, Bolu and Ktahya, respectively. The last row of Tables 4-6 indicates the per-month availability of labor and hours for the facilities. Inventory of the various products may be stored from month 1 to month 2 incurring inventory-storage costs equal to 8% of the costs in Table 2. Initially, that is, at the start of month 1, there is no inventory, and CoffeeIsLife would like to end the two-month planning period with no inventory. All shipping from stanbul and Bolu that goes to HepsiOrada or Trendyap must go through a special quality control process. This quality control technology is only available in Ankara. Hence, these units are first sent to Ankara, inspected, and then sent to their destination. Ankara can inspect at most 1,500 pieces every month. The corporation controls the material that goes in the coffee makers; the material requirements for each coffee maker type are given in the first column of Tables 4-6. A total of 3,500 pounds of material is available for the entire system (that is, all three facilities) in each month of the planning period. Table 4. Product-resource constraints stanbul Facility Resources Products Material Machine Labor 1b/unit hours/unit Hours/unit Professional 1.3 9 4 Advanced 1.2 9 4 Moderate 1.1 8.5 3 Basic 1 3 TOTAL 10000 6000 AVAIABLE Table 5. Product-resource constraints - Bolu Facility Resources Products Material Machine Labor lb/unit hours/unit Hours/unit Professional 1.4 9 4.5 Advanced 1.1 8 4.5 Moderate 1 7 3.5 Basic 1.1 7 3.5 TOTAL 12500 5000 AVAILABLE Table 6. Product-resource constraints - Ktahya Facility Resources Products Material Machine Labor Ib/unit hours/unit Hours/unit Professional 1.3 8.5 4.5 Advanced 1.3 8.5 4 Moderate 1.1 7.5 3.5 Basic 1.1 7.5 TOTAL 6000 3000 AVAILABLE Due to the demand forecasts of the finance department, the maximum sales in each month for each customer-product pair is limited. These restrictions are given Table 7. Table 7. Maximum product sales (number of units) Customers Products N12 Trendyap Hepsi Orada Professional 300 400 200 Advanced 300 200 500 Moderate 400 300 300 Basic 200 400 200 CoffeelsLife gives importance to scientific approaches and desires to improve their operations in Turkey. They contacted with your consulting firm where you are creating optimization projects for famous companies. Your company and CoffeelsLife made an agreement and you are expected prepare a file where you will have recommendations for improvement. An improvement file must include a plan for production and shipping as well as the cost and revenue generated from each facility. You should also address the following sensitivity analysis issues in your file (consider each issue independently): CoffeelsLife, Inc., one of the world's famous French Press coffee maker producers, is founded in 1995 in the United States. With the 25 years in the business and 325 store locations in the United States, the company decided to expand its business to Europe in 2015. Turkey was one of the candidate countries and the company opened three production facilities in stanbul, Bolu, and Ktahya. Due to the special marketing strategy of the company, they decided to sell their French Press coffee makers to only Turkey's biggest e-commerce businesses. Marketing department made agreements with three different companies HepsiOrada, Trendyap and N12. The production facilities produce four types of coffee makers: Basic, Moderate, Advanced and Professional. Any type product can be produced in any of the three different facilities. The products produced in different facilities are identical. However, the production processes are different. Hence, each facility has its own requirements and unit production costs. CoffeelsLife sells these four types of products to HepsiOrada, Trendyap and N12. Product selling prices per unit product are given in Table 1. Table 1. Selling price (S) per unit Customers Products N12 Trendyap HepsiOrada Professional 30 28 30 Advanced 26 24 23 Moderate 20 20 19 Basic 19 18 18 contains the production costs for each product-facility pair. shows the transportation costs from each facility to each customer. The planning problem is for two months. The production costs listed in Table 2 increase by 10% in month 2; all other data (resource-requirements, demands, sales prices, shipping costs) is unchanged for month 2. Table 2. Production costs (S) per unit Facilities Bolu Products stanbul Professional 26 Advanced 18 Moderate 16 Basic 14 24 20 17 13 Ktahya 23 19 15 14 Table 3. Shipping costs ($) per unit Customers Plants N12 Trendyap HepsiOrada Ktahya 4.3 3.5 2.4 Bolu 3 3.5 2.2 stanbul 4.1 3.6 2 The workers and machines in the factories have limited working hours. These product type- resource restrictions are given in Tables 4-6 for the facilities in stanbul, Bolu and Ktahya, respectively. The last row of Tables 4-6 indicates the per-month availability of labor and hours for the facilities. Inventory of the various products may be stored from month 1 to month 2 incurring inventory-storage costs equal to 8% of the costs in Table 2. Initially, that is, at the start of month 1, there is no inventory, and CoffeeIsLife would like to end the two-month planning period with no inventory. All shipping from stanbul and Bolu that goes to HepsiOrada or Trendyap must go through a special quality control process. This quality control technology is only available in Ankara. Hence, these units are first sent to Ankara, inspected, and then sent to their destination. Ankara can inspect at most 1,500 pieces every month. The corporation controls the material that goes in the coffee makers; the material requirements for each coffee maker type are given in the first column of Tables 4-6. A total of 3,500 pounds of material is available for the entire system (that is, all three facilities) in each month of the planning period. Table 4. Product-resource constraints stanbul Facility Resources Products Material Machine Labor 1b/unit hours/unit Hours/unit Professional 1.3 9 4 Advanced 1.2 9 4 Moderate 1.1 8.5 3 Basic 1 3 TOTAL 10000 6000 AVAIABLE Table 5. Product-resource constraints - Bolu Facility Resources Products Material Machine Labor lb/unit hours/unit Hours/unit Professional 1.4 9 4.5 Advanced 1.1 8 4.5 Moderate 1 7 3.5 Basic 1.1 7 3.5 TOTAL 12500 5000 AVAILABLE Table 6. Product-resource constraints - Ktahya Facility Resources Products Material Machine Labor Ib/unit hours/unit Hours/unit Professional 1.3 8.5 4.5 Advanced 1.3 8.5 4 Moderate 1.1 7.5 3.5 Basic 1.1 7.5 TOTAL 6000 3000 AVAILABLE Due to the demand forecasts of the finance department, the maximum sales in each month for each customer-product pair is limited. These restrictions are given Table 7. Table 7. Maximum product sales (number of units) Customers Products N12 Trendyap Hepsi Orada Professional 300 400 200 Advanced 300 200 500 Moderate 400 300 300 Basic 200 400 200 CoffeelsLife gives importance to scientific approaches and desires to improve their operations in Turkey. They contacted with your consulting firm where you are creating optimization projects for famous companies. Your company and CoffeelsLife made an agreement and you are expected prepare a file where you will have recommendations for improvement. An improvement file must include a plan for production and shipping as well as the cost and revenue generated from each facility. You should also address the following sensitivity analysis issues in your file (consider each issue independently)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock