Question: 1. {Summarize the methodology used to determine the optimal solution and any relevant factors or assumptions that entered into the evaluation. You are summarizing the

1. {Summarize the methodology used to determine the optimal solution and any relevant factors or assumptions that entered into the evaluation. You are summarizing the ABC problem.

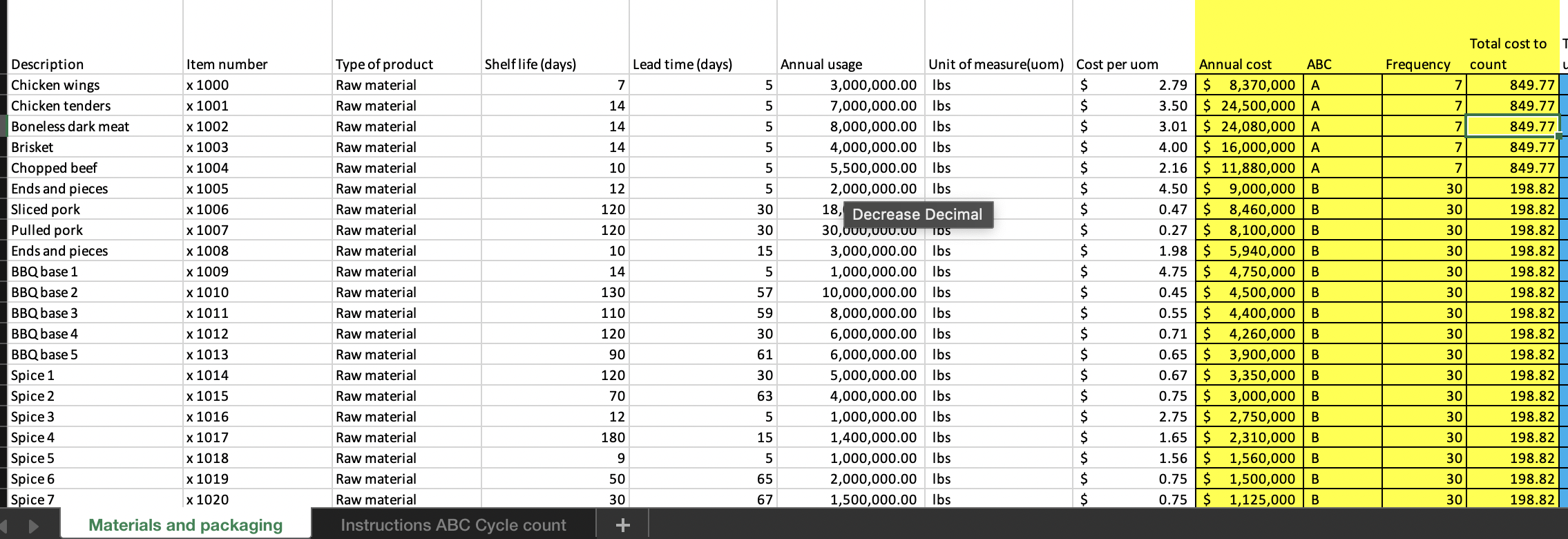

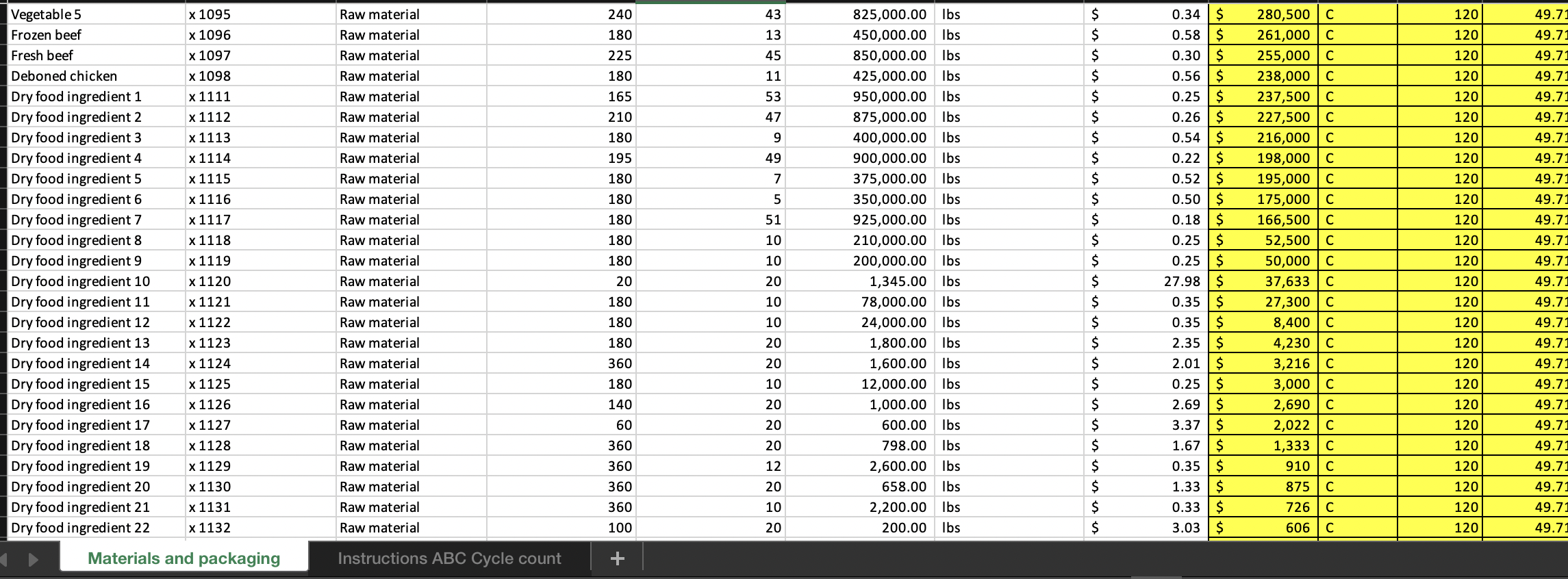

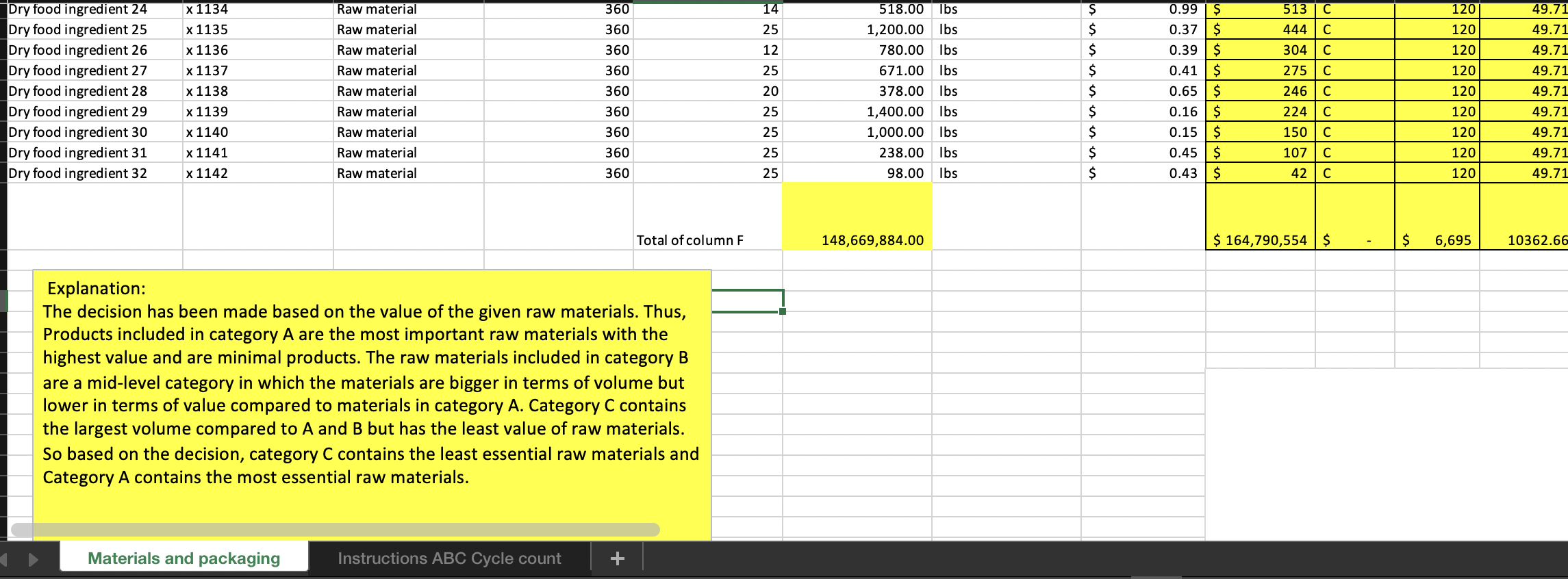

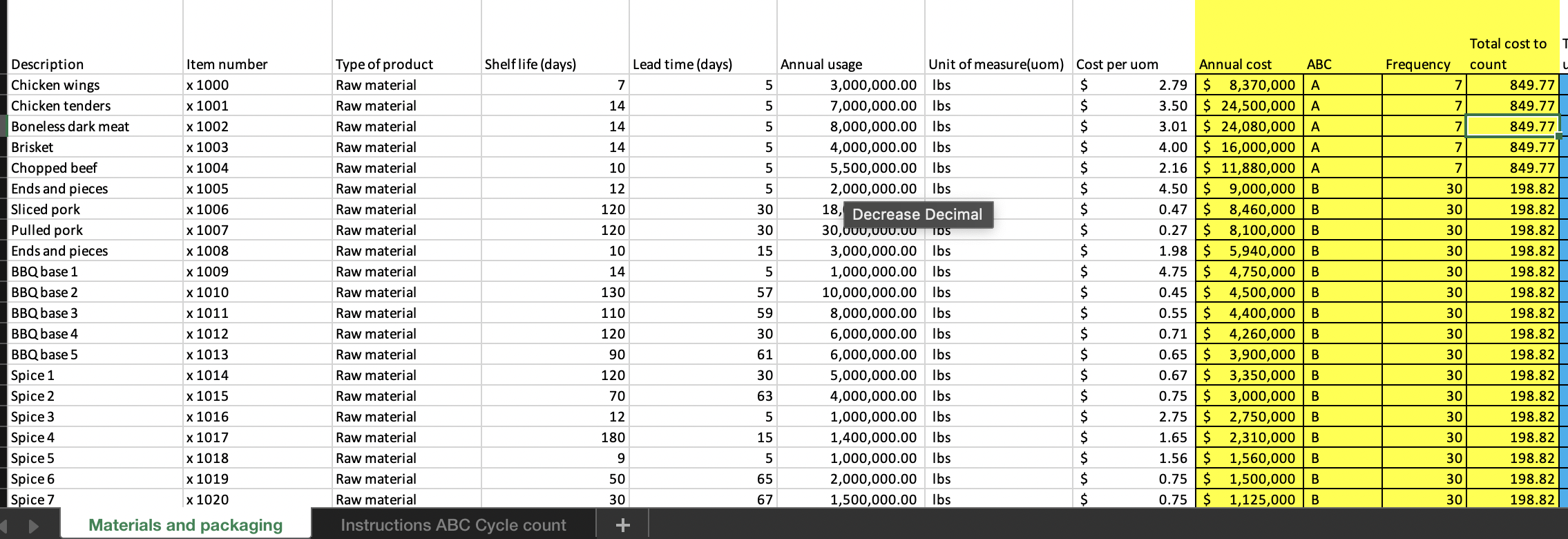

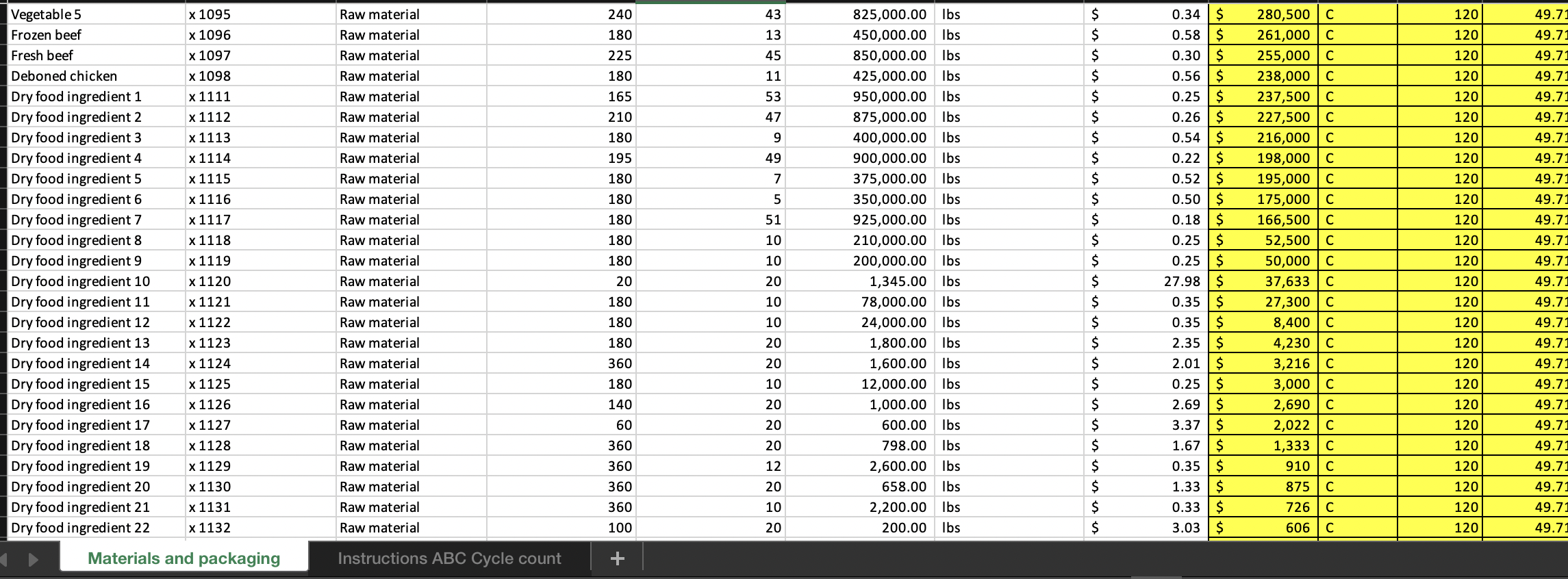

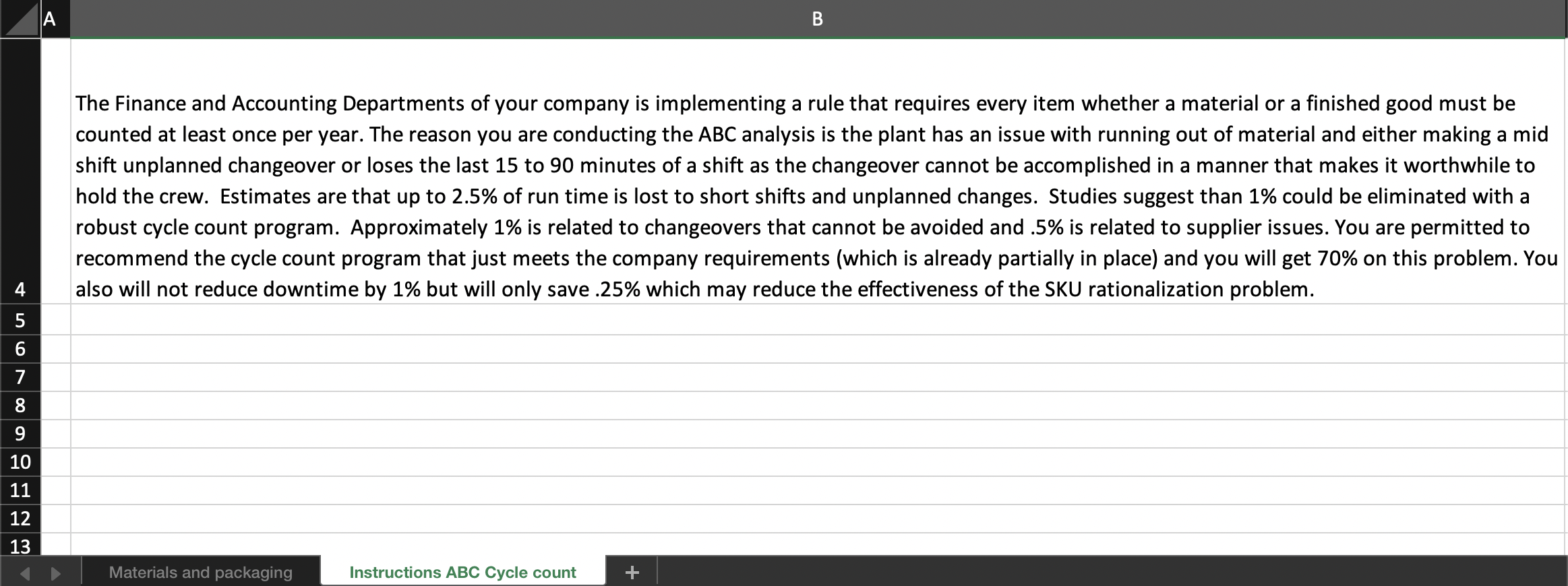

2. Conduct an ABC analysis to develop a cycle count program

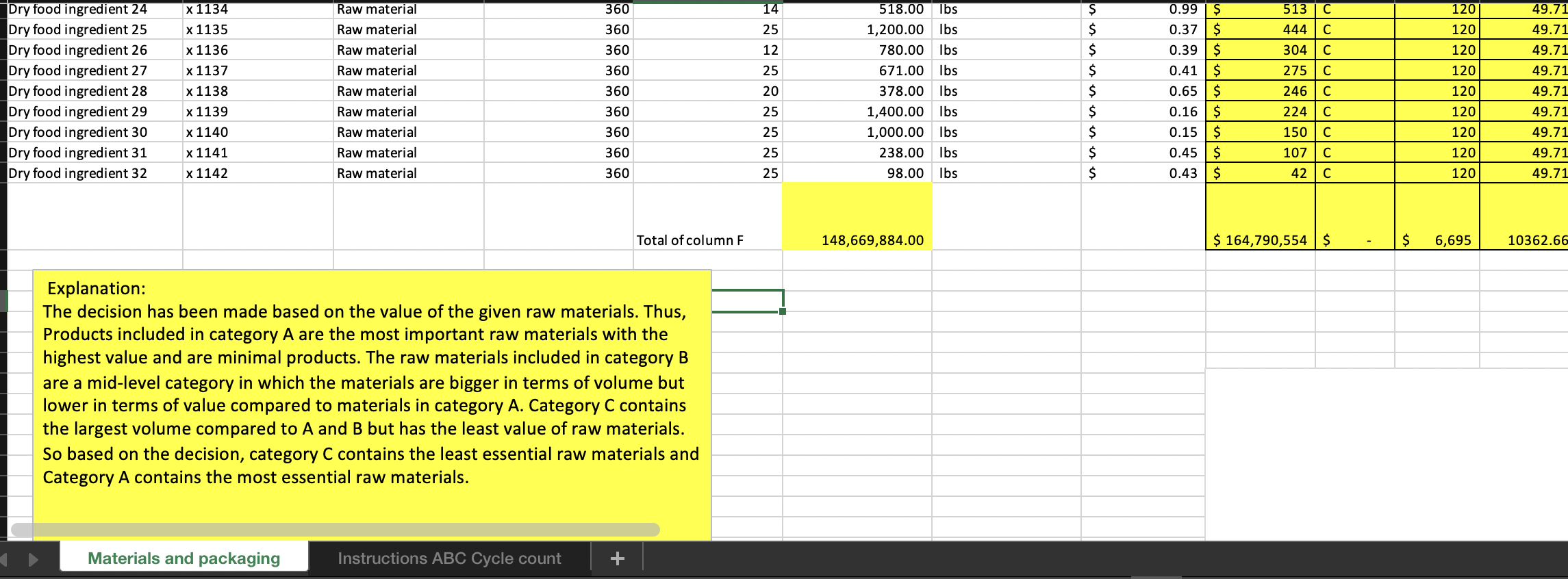

Total cost to T Shelf life (days) Lead time (days) Annual usage count 7 14 5 5 Frequency 7 7 849.77 849.77 14 5 7 849.77 849.77 14 5 7 10 5 7 5 30 12 120 849.77 198.82 198.82 198.82 30 30 120 30 30 10 15 30 198.82 198.82 14 30 Description Item number Chicken wings x 1000 Chicken tenders x 1001 Boneless dark meat x 1002 Brisket x 1003 Chopped beef x 1004 Ends and pieces x 1005 Sliced pork x 1006 Pulled pork x 1007 Ends and pieces x 1008 BBQ base 1 x 1009 BBQ base 2 x 1010 BBQ base 3 x 1011 BBQ base 4 x 1012 BBQ base 5 x 1013 Spice 1 x 1014 Spice 2 x 1015 Spice 3 x 1016 Spice 4 x 1017 Spice 5 x 1018 Spice 6 x 1019 Spice 7 x 1020 Materials and packaging Type of product Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 5 57 Unit of measure(uom) Cost per uom Annual cost ABC 3,000,000.00 lbs $ 2.79$ 8,370,000 A 7,000,000.00 lbs $ 3.50 $ 24,500,000 A 8,000,000.00 lbs $ 3.01 $ 24,080,000 A 4,000,000.00 lbs $ 4.00 $ 16,000,000 A 5,500,000.00 lbs $ 2.16 $ 11,880,000 A 2,000,000.00 lbs $ 4.50$ 9,000,000 B 18, Decrease Decimal $ 0.47 $ 8,460,000 B 30,000,000.00 10S $ 0.27$ 8,100,000 B 3,000,000.00 lbs $ 1.98$ 5,940,000 B 1,000,000.00 lbs $ 4.75 $ 4,750,000 B 10,000,000.00 lbs $ 0.45 $ 4,500,000 B 8,000,000.00 lbs $ 0.55$ 4,400,000 B 6,000,000.00 lbs $ 0.71 $ 4,260,000 B 6,000,000.00 lbs $ 0.65 $ 3,900,000 B 5,000,000.00 Ibs $ 0.67$ 3,350,000 B 4,000,000.00 lbs $ 0.75$ 3,000,000 B 1,000,000.00 lbs $ 2.75$ 2,750,000 B 1,400,000.00 lbs $ 1.65 $ 2,310,000 B 1,000,000.00 lbs $ 1.56 $ 1,560,000 B 2,000,000.00 lbs $ 0.75$ 1,500,000 1,500,000.00 lbs $ 0.75$ 1,125,000 B 130 30 110 59 30 120 30 30 90 61 30 198.82 198.82 198.82 198.82 198.82 198.82 198.82 198.82 30 30 120 70 12 30 63 5 30 180 15 30 III 9 5 30 198.82 198.82 50 30 65 67 30 30 198.82 Instructions ABC Cycle count + 240 43 120 180 13 $ $ $ $ 45 225 180 11 8 B Fu8n99 120 120 120 120 120 120 53 $ 47 165 210 180 195 49 120 180 7 120 180 5 180 180 51 10 180 10 Vegetable 5 x 1095 Frozen beef x 1096 Fresh beef x 1097 Deboned chicken x 1098 Dry food ingredient 1 x 1111 Dry food ingredient 2 x 1112 Dry food ingredient 3 x 1113 Dry food ingredient 4 x 1114 Dry food ingredient 5 x 1115 Dry food ingredient 6 x 1116 Dry food ingredient 7 x 1117 Dry food ingredient 8 x 1118 Dry food ingredient 9 x 1119 Dry food ingredient 10 x 1120 Dry food ingredient 11 x 1121 Dry food ingredient 12 x 1122 Dry food ingredient 13 x 1123 Dry food ingredient 14 x 1124 Dry food ingredient 15 x 1125 Dry food ingredient 16 x 1126 Dry food ingredient 17 x 1127 Dry food ingredient 18 x 1128 Dry food ingredient 19 x 1129 Dry food ingredient 20 x 1130 Dry food ingredient 21 x 1131 Dry food ingredient 22 x 1132 Materials and packaging Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 825,000.00 lbs 450,000.00 lbs 850,000.00 lbs 425,000.00 lbs 950,000.00 lbs 875,000.00 lbs 400,000.00 lbs 900,000.00 lbs 375,000.00 lbs 350,000.00 lbs 925,000.00 lbs 210,000.00 lbs 200,000.00 lbs 1,345.00 lbs 78,000.00 lbs 24,000.00 lbs 1,800.00 lbs 1,600.00 lbs 12,000.00 lbs 1,000.00 lbs 600.00 lbs 798.00 lbs 2,600.00 lbs 658.00 lbs 2,200.00 lbs 200.00 lbs 280,500C 261,000C 255,000 C 238,000 C 237,500C 227,500 C 216,000C 198,000C 195,000 175,000 166,500 52,500C 50,000C 37,633C 27,300C 8,400 C 4,230C 3,216 C 3,000 2,690 2,022 C 1,333 910 C 0.34 $ 0.58 $ 0.30 $ 0.56 $ 0.25$ 0.26 $ 0.54 $ 0.22 $ 0.52 $ 0.50 $ 0.18$ 0.25$ 0.25$ 27.98$ 0.35$ 0.35$ 2.35 $ 2.01 $ 0.25 $ 2.69 $ 3.37 $ 1.67$ 0.35 $ 1.33 $ 0.33 $ 3.03 $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ 120 120 120 120 120 120 120 120 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 20 10 20 180 180 180 10 20 360 20 120 180 10 120 140 20 20 60 360 360 20 12 $ 120 120 120 120 120 120 120 875 C 360 360 100 20 10 20 $ $ $ C 726 606 49.71 Instructions ABC Cycle count + + x 1134 Raw material 360 14 C 513 444 120 120 x 1135 x 1136 x 1137 360 360 25 12 C 120 304 275 360 25 C 120 Dry food ingredient 24 Dry food ingredient 25 Dry food ingredient 26 Dry food ingredient 27 Dry food ingredient 28 Dry food ingredient 29 Dry food ingredient 30 Dry food ingredient 31 Dry food ingredient 32 x 1138 360 20 518.00 Ibs 1,200.00 lbs 780.00 Ibs 671.00 lbs 378.00 lbs 1,400.00 lbs 1,000.00 Ibs 238.00 lbs 98.00 lbs $ $ $ $ $ $ $ $ $ 0.99 $ 0.37 $ 0.39 $ 0.41 $ 0.65 $ 0.16 $ 0.15$ 0.45 $ 0.43 $ Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 246 120 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 x 1139 360 25 224 C 120 x 1140 x 1141 x 1142 360 360 25 25 25 150 107 120 120 120 360 42 Total of column F 148,669,884.00 $ 164,790,554 $ $ 6,695 10362.66 Explanation: The decision has been made based on the value of the given raw materials. Thus, Products included in category A are the most important raw materials with the highest value and are minimal products. The raw materials included in category B are a mid-level category in which the materials are bigger in terms of volume but lower in terms of value compared to materials in category A. Category C contains the largest volume compared to A and B but has the least value of raw materials. So based on the decision, category C contains the least essential raw materials and Category A contains the most essential raw materials. Materials and packaging Instructions ABC Cycle count + B a a The Finance and Accounting Departments of your company is implementing a rule that requires every item whether a material or a finished good must be counted at least once per year. The reason you are conducting the ABC analysis is the plant has an issue with running out of material and either making a mid shift unplanned changeover or loses the last 15 to 90 minutes of a shift as the changeover cannot be accomplished in a manner that makes it worthwhile to hold the crew. Estimates are that up to 2.5% of run time is lost to short shifts and unplanned changes. Studies suggest than 1% could be eliminated with a robust cycle count program. Approximately 1% is related to changeovers that cannot be avoided and .5% is related to supplier issues. You are permitted to recommend the cycle count program that just meets the company requirements (which is already partially in place) and you will get 70% on this problem. You also will not reduce downtime by 1% but will only save .25% which may reduce the effectiveness of the SKU rationalization problem. 4 5 in n 6 7 8 9 10 11 12 13 Materials and packaging Instructions ABC Cycle count + Total cost to T Shelf life (days) Lead time (days) Annual usage count 7 14 5 5 Frequency 7 7 849.77 849.77 14 5 7 849.77 849.77 14 5 7 10 5 7 5 30 12 120 849.77 198.82 198.82 198.82 30 30 120 30 30 10 15 30 198.82 198.82 14 30 Description Item number Chicken wings x 1000 Chicken tenders x 1001 Boneless dark meat x 1002 Brisket x 1003 Chopped beef x 1004 Ends and pieces x 1005 Sliced pork x 1006 Pulled pork x 1007 Ends and pieces x 1008 BBQ base 1 x 1009 BBQ base 2 x 1010 BBQ base 3 x 1011 BBQ base 4 x 1012 BBQ base 5 x 1013 Spice 1 x 1014 Spice 2 x 1015 Spice 3 x 1016 Spice 4 x 1017 Spice 5 x 1018 Spice 6 x 1019 Spice 7 x 1020 Materials and packaging Type of product Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 5 57 Unit of measure(uom) Cost per uom Annual cost ABC 3,000,000.00 lbs $ 2.79$ 8,370,000 A 7,000,000.00 lbs $ 3.50 $ 24,500,000 A 8,000,000.00 lbs $ 3.01 $ 24,080,000 A 4,000,000.00 lbs $ 4.00 $ 16,000,000 A 5,500,000.00 lbs $ 2.16 $ 11,880,000 A 2,000,000.00 lbs $ 4.50$ 9,000,000 B 18, Decrease Decimal $ 0.47 $ 8,460,000 B 30,000,000.00 10S $ 0.27$ 8,100,000 B 3,000,000.00 lbs $ 1.98$ 5,940,000 B 1,000,000.00 lbs $ 4.75 $ 4,750,000 B 10,000,000.00 lbs $ 0.45 $ 4,500,000 B 8,000,000.00 lbs $ 0.55$ 4,400,000 B 6,000,000.00 lbs $ 0.71 $ 4,260,000 B 6,000,000.00 lbs $ 0.65 $ 3,900,000 B 5,000,000.00 Ibs $ 0.67$ 3,350,000 B 4,000,000.00 lbs $ 0.75$ 3,000,000 B 1,000,000.00 lbs $ 2.75$ 2,750,000 B 1,400,000.00 lbs $ 1.65 $ 2,310,000 B 1,000,000.00 lbs $ 1.56 $ 1,560,000 B 2,000,000.00 lbs $ 0.75$ 1,500,000 1,500,000.00 lbs $ 0.75$ 1,125,000 B 130 30 110 59 30 120 30 30 90 61 30 198.82 198.82 198.82 198.82 198.82 198.82 198.82 198.82 30 30 120 70 12 30 63 5 30 180 15 30 III 9 5 30 198.82 198.82 50 30 65 67 30 30 198.82 Instructions ABC Cycle count + 240 43 120 180 13 $ $ $ $ 45 225 180 11 8 B Fu8n99 120 120 120 120 120 120 53 $ 47 165 210 180 195 49 120 180 7 120 180 5 180 180 51 10 180 10 Vegetable 5 x 1095 Frozen beef x 1096 Fresh beef x 1097 Deboned chicken x 1098 Dry food ingredient 1 x 1111 Dry food ingredient 2 x 1112 Dry food ingredient 3 x 1113 Dry food ingredient 4 x 1114 Dry food ingredient 5 x 1115 Dry food ingredient 6 x 1116 Dry food ingredient 7 x 1117 Dry food ingredient 8 x 1118 Dry food ingredient 9 x 1119 Dry food ingredient 10 x 1120 Dry food ingredient 11 x 1121 Dry food ingredient 12 x 1122 Dry food ingredient 13 x 1123 Dry food ingredient 14 x 1124 Dry food ingredient 15 x 1125 Dry food ingredient 16 x 1126 Dry food ingredient 17 x 1127 Dry food ingredient 18 x 1128 Dry food ingredient 19 x 1129 Dry food ingredient 20 x 1130 Dry food ingredient 21 x 1131 Dry food ingredient 22 x 1132 Materials and packaging Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 825,000.00 lbs 450,000.00 lbs 850,000.00 lbs 425,000.00 lbs 950,000.00 lbs 875,000.00 lbs 400,000.00 lbs 900,000.00 lbs 375,000.00 lbs 350,000.00 lbs 925,000.00 lbs 210,000.00 lbs 200,000.00 lbs 1,345.00 lbs 78,000.00 lbs 24,000.00 lbs 1,800.00 lbs 1,600.00 lbs 12,000.00 lbs 1,000.00 lbs 600.00 lbs 798.00 lbs 2,600.00 lbs 658.00 lbs 2,200.00 lbs 200.00 lbs 280,500C 261,000C 255,000 C 238,000 C 237,500C 227,500 C 216,000C 198,000C 195,000 175,000 166,500 52,500C 50,000C 37,633C 27,300C 8,400 C 4,230C 3,216 C 3,000 2,690 2,022 C 1,333 910 C 0.34 $ 0.58 $ 0.30 $ 0.56 $ 0.25$ 0.26 $ 0.54 $ 0.22 $ 0.52 $ 0.50 $ 0.18$ 0.25$ 0.25$ 27.98$ 0.35$ 0.35$ 2.35 $ 2.01 $ 0.25 $ 2.69 $ 3.37 $ 1.67$ 0.35 $ 1.33 $ 0.33 $ 3.03 $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ 120 120 120 120 120 120 120 120 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 20 10 20 180 180 180 10 20 360 20 120 180 10 120 140 20 20 60 360 360 20 12 $ 120 120 120 120 120 120 120 875 C 360 360 100 20 10 20 $ $ $ C 726 606 49.71 Instructions ABC Cycle count + + x 1134 Raw material 360 14 C 513 444 120 120 x 1135 x 1136 x 1137 360 360 25 12 C 120 304 275 360 25 C 120 Dry food ingredient 24 Dry food ingredient 25 Dry food ingredient 26 Dry food ingredient 27 Dry food ingredient 28 Dry food ingredient 29 Dry food ingredient 30 Dry food ingredient 31 Dry food ingredient 32 x 1138 360 20 518.00 Ibs 1,200.00 lbs 780.00 Ibs 671.00 lbs 378.00 lbs 1,400.00 lbs 1,000.00 Ibs 238.00 lbs 98.00 lbs $ $ $ $ $ $ $ $ $ 0.99 $ 0.37 $ 0.39 $ 0.41 $ 0.65 $ 0.16 $ 0.15$ 0.45 $ 0.43 $ Raw material Raw material Raw material Raw material Raw material Raw material Raw material Raw material 246 120 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 49.71 x 1139 360 25 224 C 120 x 1140 x 1141 x 1142 360 360 25 25 25 150 107 120 120 120 360 42 Total of column F 148,669,884.00 $ 164,790,554 $ $ 6,695 10362.66 Explanation: The decision has been made based on the value of the given raw materials. Thus, Products included in category A are the most important raw materials with the highest value and are minimal products. The raw materials included in category B are a mid-level category in which the materials are bigger in terms of volume but lower in terms of value compared to materials in category A. Category C contains the largest volume compared to A and B but has the least value of raw materials. So based on the decision, category C contains the least essential raw materials and Category A contains the most essential raw materials. Materials and packaging Instructions ABC Cycle count + B a a The Finance and Accounting Departments of your company is implementing a rule that requires every item whether a material or a finished good must be counted at least once per year. The reason you are conducting the ABC analysis is the plant has an issue with running out of material and either making a mid shift unplanned changeover or loses the last 15 to 90 minutes of a shift as the changeover cannot be accomplished in a manner that makes it worthwhile to hold the crew. Estimates are that up to 2.5% of run time is lost to short shifts and unplanned changes. Studies suggest than 1% could be eliminated with a robust cycle count program. Approximately 1% is related to changeovers that cannot be avoided and .5% is related to supplier issues. You are permitted to recommend the cycle count program that just meets the company requirements (which is already partially in place) and you will get 70% on this problem. You also will not reduce downtime by 1% but will only save .25% which may reduce the effectiveness of the SKU rationalization problem. 4 5 in n 6 7 8 9 10 11 12 13 Materials and packaging Instructions ABC Cycle count +