Question: 1. Using the information regarding the Production Process as described in Chapter 10 , pp. 317-321, create a BPMN (Business Process Modeling Notation) for this

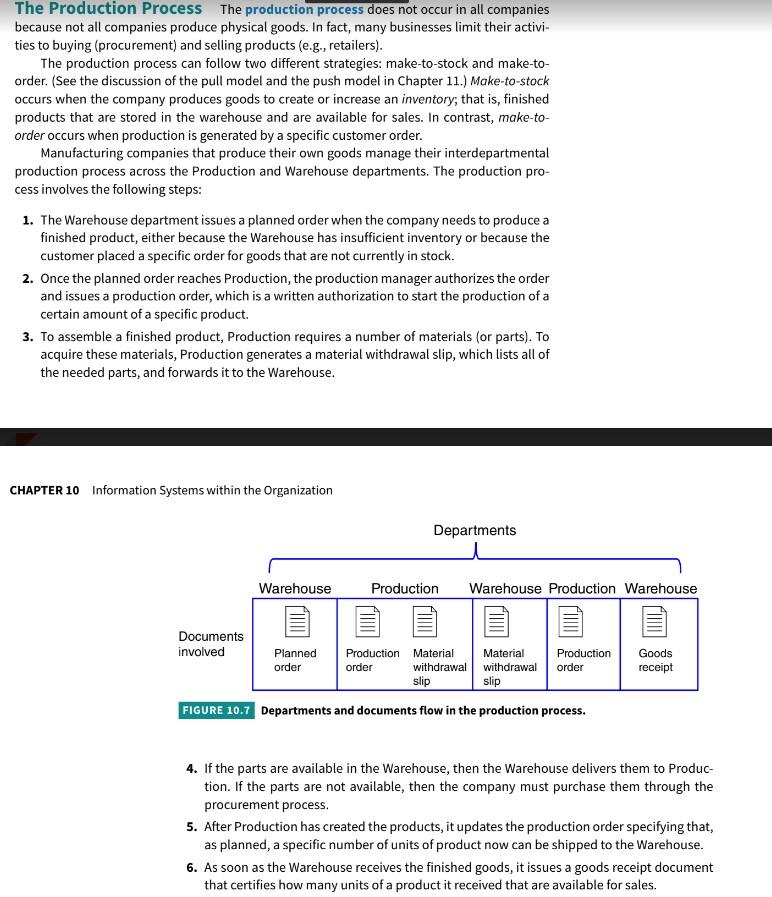

1. Using the information regarding the Production Process as described in Chapter 10 , pp. 317-321, create a BPMN (Business Process Modeling Notation) for this process. Microsoft Visio is suggested as the tool to create this BPMN (a cross-functional flowchart), but not required. Your instructor will provide an explanation of a BPMN, its structure and purpose. ( 25 points) The Production Process The production process does not occur in all companies because not all companies produce physical goods. In fact, many businesses limit their activities to buying (procurement) and selling products (e.g., retailers). The production process can follow two different strategies: make-to-stock and make-toorder. (See the discussion of the pull model and the push model in Chapter 11.) Make-to-stock occurs when the company produces goods to create or increase an inventory; that is, finished products that are stored in the warehouse and are available for sales. In contrast, make-toorder occurs when production is generated by a specific customer order. Manufacturing companies that produce their own goods manage their interdepartmental production process across the Production and Warehouse departments. The production process involves the following steps: 1. The Warehouse department issues a planned order when the company needs to produce a finished product, either because the Warehouse has insufficient inventory or because the customer placed a specific order for goods that are not currently in stock. 2. Once the planned order reaches Production, the production manager authorizes the order and issues a production order, which is a written authorization to start the production of a certain amount of a specific product. 3. To assemble a finished product, Production requires a number of materials (or parts). To acquire these materials, Production generates a material withdrawal slip, which lists all of the needed parts, and forwards it to the Warehouse. CHAPTER 10 Information Systems within the Organization Departments and documents flow in the production process. 4. If the parts are available in the Warehouse, then the Warehouse delivers them to Production. If the parts are not available, then the company must purchase them through the procurement process. 5. After Production has created the products, it updates the production order specifying that, as planned, a specific number of units of product now can be shipped to the Warehouse. 6. As soon as the Warehouse receives the finished goods, it issues a goods receipt document that certifies how many units of a product it received that are available for sales

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts