Question: 1. Using the Kraliic Supplier Segmentation framework, categorize the four products described in the case (quartz sand, saw blades, copper sputtering equipment, face masks). Provide

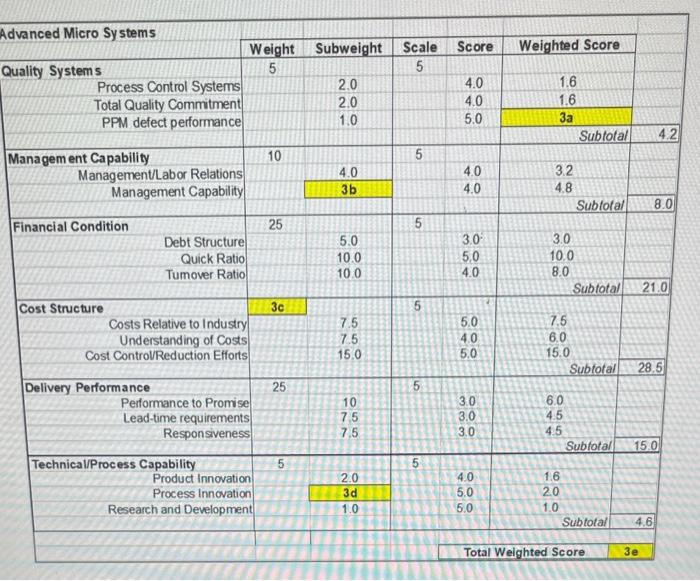

1. Using the Kraliic Supplier Segmentation framework, categorize the four products described in the case (quartz sand, saw blades, copper sputtering equipment, face masks). Provide a brief explanation for why you categorized each item the way you did. 2. Which of the four products described in the case do you think that Jimmy's scorecard could best be used for? Why? 3. Calculate the missing values in Jimmy's scorecard. a. b. c. d. e. 4. How would you reply to Kris' suggestion about having one scorecard for all of AMS's suppliers? 5. How would you reply to Meri's comment that Jimmy's scorecard should have weights and subucights that are all the same? 6. Pick one of the four products described in the case and explain how you would go about managing the purchasing process for that item. Include the following: a. Where you think the product falls in the Kralic Supplier Segmentation framework b. Develop a scorecard that could be used to assess suppliers of that product. Include five categories and at least two criteria in each category. c. Discuss why you chose the categories and weights that you did. d. Discuss potential challenges in assessing suppliers of this product. e. Discuss how you could use your scorecard to drive continuous improvement with suppliers of this product. Advanced Micro Systems (AMS) is a manufacturer of computer processors located in Grand Rapids, Michigan. 1 Founded in the 1980s, the company has unique design methods, which allows them to design processors specifically to their customers' different processing requirements. AMS has built on this deep technical knowledge to create a competitive position servicing the specific processing needs of business clients in the information technology, biotechnology, and defense industries. The company is relatively small, with around 1,000 employees, and mainly produces customized solutions for its clients. Production Process 2 AMS's production process is quite complicated. Described below is an abbreviated version of the steps AMS undertakes when creating processors for clients. Step 1: Silicone dioxide (SiO2) is first extracted from quartz sand. AMS then subjects the extracted SiO2 to a rigorous purification process to produce the electronic grade silicon used in semiconductors, typically 99.9999% pure. This electronic grade silicon is then melted into a 100-kilogram (220-pound) ingot. This ingot is then ready for use in Step 2. Step 2: The ingot is cut with a very thin saw into individual silicon slices called wafers. Wafers are polished to a flawless mirror-smooth surface. A complex pattern of conductive and non-conductive traces is then etched onto the surface of the wafers using a photolithographic printing process. The finished wafers represent the basic platform for all of the different processors that AMS produces in the next stage. Step 3: Copper transistors are created and an intricate set of copper wire connections are developed. It is at this stage that AMS creates is unique value for customers. The complex system of copper wire connections determines the individual performance of each computer processor. Getting this stage right is therefore absolutely critical for AMS. Purchasing \& Supply Chain Management at AMS Because AMS is relatively small, it has never fully developed a supply chain management department. In particular the company has not invested adequately in managing its suppliers. As a result, the company is not as efficient as its competitors when it comes to managing the flow of information, money, and materials from suppliers and customers. Inefficiencies in the supply chain have translated into operating costs that exceed the industry average. These high operating costs are now eroding AMS's profitability. Top management recognizes that AMS needs to do a better job in purchasing and supply chain management. The company had hired a summer intern - Jimmy - to start work in this area. Jimmy has since left and the company decided it needed a full time Director of Purchasing \& Supply Chain Management. After an exhaustive search, they decided that you have the right mix of qualifications and enthusiasm to tackle the job. They offered you the position and you accepted. Your mandate is to create some solid processes around the company's purchasing and supply chain activities. Advanced Micro Sy stems But first, you need to do a little cleaning up after Jimmy...You discover that Jimmy began creating a supplier scorecard, but failed to completely fill out all the scorecard values. In addition to not fully completing the supplier score card, Jimmy did not indicate how he intended to use the scorecard. Over the summer, Jimmy was tasked with developing a scorecard for buying four different products: Quartz Sand - AMS uses tens of thousands of pounds of quartz sand each year. Quartz sand has a wide variety of industrial uses, from filtration systems to foundry presses to high tech applications like computer processor manufacturing. Consequently, there are many suppliers of quartz sand who compete mainly on the price of the sand. However, AMS has found that a specific grade of quartz sand provides the highest yield (lowest scrap) in their manufacturing process. Suppliers of quartz sand must be thoroughly reviewed for the quality of their sand to ensure that they will ship to AMS's specific grade. Currently, AMS spends a lot of time and effort dealing with dozens of quartz sand suppliers to get the cheapest prices of the day through a complicated assortment of short term contracts. - Saw Blades - These saw blades are used in the saw that cuts the quartz ingot into wafers. The saw that AMS current uses is outdated. As a result, it takes a very particular kind of saw blade that is only made by handful of specialty supply shops in Germany. AMS goes through dozens of these saw blades each year, but supply is always an issue. The lead engineer responsible for ensuring the quality of the wafer production process spends a great deal of time each month negotiating with suppliers. He has even taken up learning German to facilitate the process. Still, top management has resisted upgrading their saw to industry standard because they have other priorities. - Copper Sputtering Equipment - AMS uses specially constructed copper sputtering equipment to place the complex system of copper wire connections on each of its computer processors. Often, AMS needs to adjust the equipment to meet the specialized production needs of its clients. Adjusting the equipment requires close consultation with RobeTech, the company that makes and maintains the equipment. Although these consultations are expensive, management sees the value in the relationship with BqboTech because the equipment is necessary for satisfying AMS customer needs. Still, AMS does not seem to be getting the full benefit from the relationship. For instance, the BqbeTech issued an upgrade to its operating system last year and AMS was not notified of the change until the production team ran up against a problem. ReboTech worked with AMS to fix the problem but there was a lot of stress and bad feelings as a result. - Face Masks - Silicon wafers are produced in an environment that is 100,000 times cleaner than a hospital operating room. To maintain this level of cleanliness, employees must wear a range of protective gear including face masks. High quality face masks are very inexpensive, easily to ship, and are mass produced. Currently AMS buys its face masks and other protective gear from a company that had ties to one of the company's founders. The founder has since died, but AMS has never really taken the time to review the relationship. The chief operating officer suspects that AMS is spending too much for face masks and similar protective gear, but does not have a good idea of how the company might manage the purchase of these items more effectively. As you are trying to figure out Jimmy's scorecard, Meri walks in. Meri is a process engineer interested in learning more about purchasing and supply chain management. Meri looks at the scorecard you're working on and says, "That scorecard doesn't make any sense to me. The weights and the subweights are all different. Shouldn't they should be all the same?" This gets you into a conversation with Meri about the role of scorecards and supplier management. By the time you're finished talking with Meri, you are late for your first meeting with Kris, the Chief Operating Officer. Kris is your boss. She is excited about your coming on board to help manage AMS's suppliers. In your meeting, Kris tells you that AMS works with hundreds of suppliers to purchase thousands of products and services. "That's a lot of complexity," says Kris. "In my world, complexity is a bad thing. It leads to mistakes. My goal is to simplify. So my idea is that we should have one scorecard for all our suppliers and that we should use that scorecard to evaluate our suppliers quarterly. That way we can have a clear standard that is applied equally across all the different companies we work with. What do you think?" You head back to your office both nervous and excited about the opportunities at AMS. As you sit down at your desk, you decide that the first thing you need is a strategy

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts