Question: (10 POINTS) Suppose that demand data for widgets made by XYZ Inc. is given below. Using an appropriate method (level chase or mixed), plan the

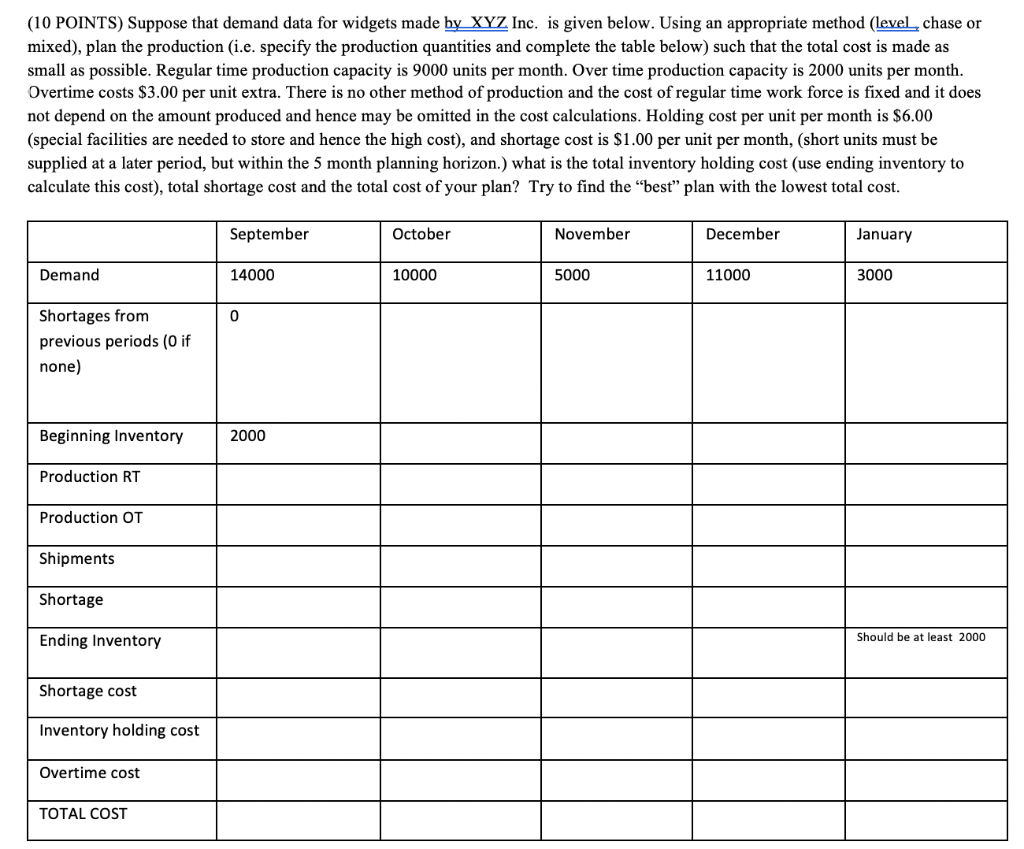

(10 POINTS) Suppose that demand data for widgets made by XYZ Inc. is given below. Using an appropriate method (level chase or mixed), plan the production (i.e. specify the production quantities and complete the table below) such that the total cost is made as small as possible. Regular time production capacity is 9000 units per month. Over time production capacity is 2000 units per month. Overtime costs $3.00 per unit extra. There is no other method of production and the cost of regular time work force is fixed and it does not depend on the amount produced and hence may be omitted in the cost calculations. Holding cost per unit per month is $6.00 (special facilities are needed to store and hence the high cost), and shortage cost is $1.00 per unit per month, (short units must be supplied at a later period, but within the 5 month planning horizon.) what is the total inventory holding cost (use ending inventory to calculate this cost), total shortage cost and the total cost of your plan? Try to find the "best" plan with the lowest total cost. September October November December January Demand 14000 10000 5000 11000 3000 Shortages from previous periods (O if none) Beginning Inventory 2000 Production RT Production OT Shipments Shortage Ending Inventory Should be at least 2000 Shortage cost Inventory holding cost Overtime cost TOTAL COST Total Production needed during the 5 months = Total capacity (RT and OT) Available during the 5 months = Total cost of the Plan: (10 POINTS) Suppose that demand data for widgets made by XYZ Inc. is given below. Using an appropriate method (level chase or mixed), plan the production (i.e. specify the production quantities and complete the table below) such that the total cost is made as small as possible. Regular time production capacity is 9000 units per month. Over time production capacity is 2000 units per month. Overtime costs $3.00 per unit extra. There is no other method of production and the cost of regular time work force is fixed and it does not depend on the amount produced and hence may be omitted in the cost calculations. Holding cost per unit per month is $6.00 (special facilities are needed to store and hence the high cost), and shortage cost is $1.00 per unit per month, (short units must be supplied at a later period, but within the 5 month planning horizon.) what is the total inventory holding cost (use ending inventory to calculate this cost), total shortage cost and the total cost of your plan? Try to find the "best" plan with the lowest total cost. September October November December January Demand 14000 10000 5000 11000 3000 Shortages from previous periods (O if none) Beginning Inventory 2000 Production RT Production OT Shipments Shortage Ending Inventory Should be at least 2000 Shortage cost Inventory holding cost Overtime cost TOTAL COST Total Production needed during the 5 months = Total capacity (RT and OT) Available during the 5 months = Total cost of the Plan

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock