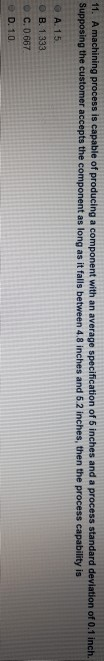

Question: 11. A machining process is capable of producing a component with an average specification of 5 inches and a process standard deviation of 0.1 inch.

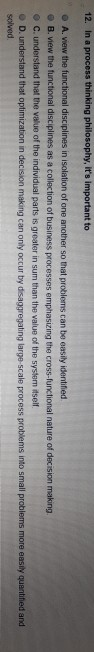

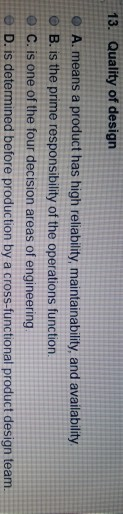

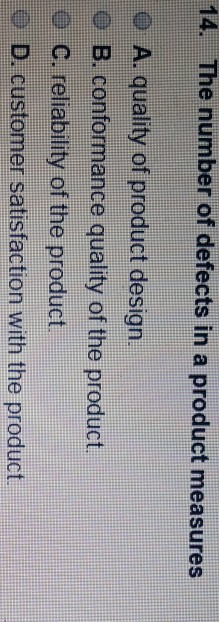

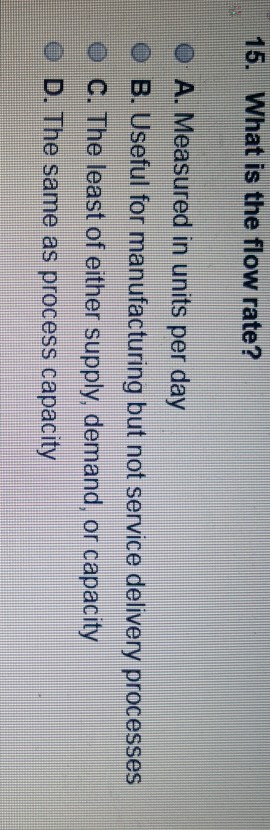

11. A machining process is capable of producing a component with an average specification of 5 inches and a process standard deviation of 0.1 inch. Supposing the customer accepts the component as long as it falls between 4.8 inches and 6.2 inches, then the process capability is A 1.5 OB. 1.333 C. 0.667 D. 1.0 12. In a process thinking philosophy, It's important to A. View the functional disciplines in isolation of one another so that problems can be easily identified B. view the functional disciplines as a collection of business processes emphasizing the cross-functional nature of decision making C. understand that the value of the individual parts is greater in sum than the value of the system itself D. understand that optimization in decision making can only occur by disaggregating large-scale process problems into small problems more easily quantified and solved 13. Quality of design A. means a product has high reliability, maintainability, and availability @ B. is the prime responsibility of the operations function C. is one of the four decision areas of engineering D. is determined before production by a cross-functional product design team. 14. The number of defects in a product measures O A. quality of product design. O B. conformance quality of the product O C. reliability of the product. D. customer satisfaction with the product 15. What is the flow rate? 0. A. Measured in units per day B. Useful for manufacturing but not service delivery processes C. The least of either supply, demand, or capacity O D. The same as process capacity

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock