Question: 1.2 Two models ( Model A and Model B) of a simple product are to be produced on an assembly line. Because of the nature

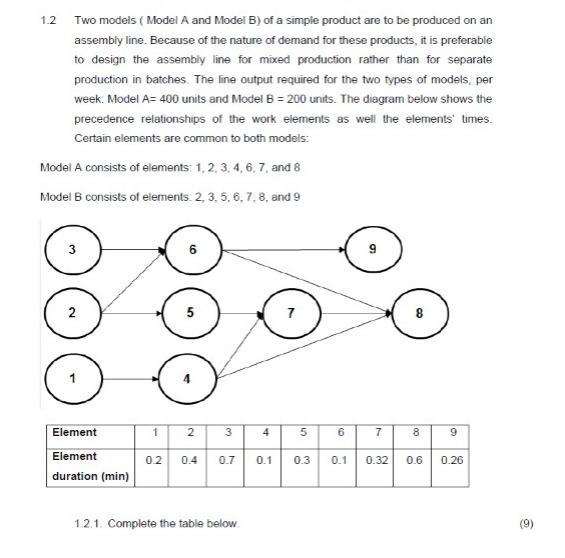

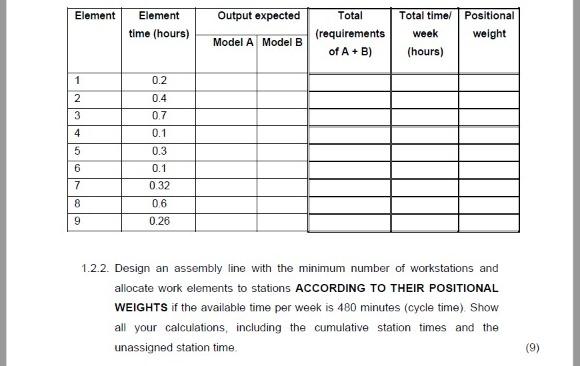

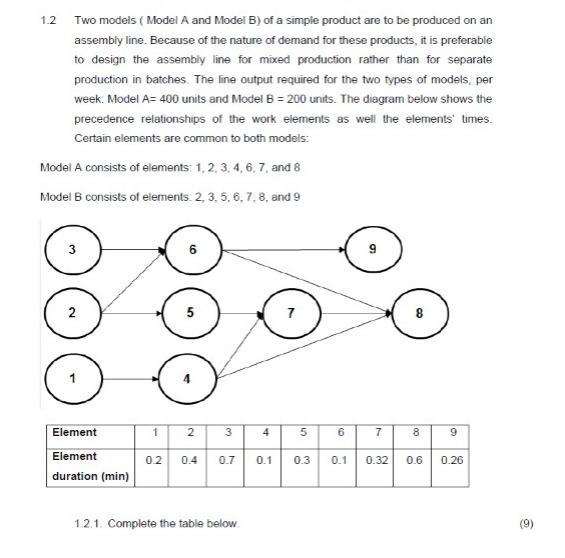

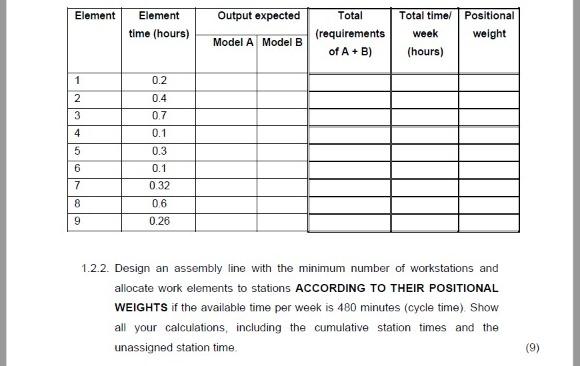

1.2 Two models ( Model A and Model B) of a simple product are to be produced on an assembly line. Because of the nature of demand for these products, it is preferable to design the assembly line for mixed production rather than for separate production in batches. The line output required for the two types of models, per week. Model A= 400 units and Model B = 200 units. The diagram below shows the precedence relationships of the work elements as well the elements times. Certain elements are common to both models: Model A consists of elements: 1, 2, 3, 4, 6, 7, and 8 Model B consists of elements: 2, 3, 5, 6, 7, 8, and 9 6 9 N 5 7 8 1 2 3 4 5 5 6 7 8 9 Element Element duration (min) 0.2 0.4 0.7 0.1 0.3 0.1 0.32 0.6 0.26 12.1. Complete the table below (9) ) Element Output expected Element time (hours) Total (requirements of A+B) Total time/ Positional week weight (hours) Model A Model B 1 2 3 4 0.2 0.4 0.7 0.1 0.3 0.1 0.32 5 6 7 8 0.6 0.26 9 1.2.2. Design an assembly line with the minimum number of workstations and allocate work elements to stations ACCORDING TO THEIR POSITIONAL WEIGHTS if the available time per week is 480 minutes (cycle time) Show all your calculations, including the cumulative station times and the unassigned station time (9) 1.2 Two models ( Model A and Model B) of a simple product are to be produced on an assembly line. Because of the nature of demand for these products, it is preferable to design the assembly line for mixed production rather than for separate production in batches. The line output required for the two types of models, per week. Model A= 400 units and Model B = 200 units. The diagram below shows the precedence relationships of the work elements as well the elements times. Certain elements are common to both models: Model A consists of elements: 1, 2, 3, 4, 6, 7, and 8 Model B consists of elements: 2, 3, 5, 6, 7, 8, and 9 6 9 N 5 7 8 1 2 3 4 5 5 6 7 8 9 Element Element duration (min) 0.2 0.4 0.7 0.1 0.3 0.1 0.32 0.6 0.26 12.1. Complete the table below (9) ) Element Output expected Element time (hours) Total (requirements of A+B) Total time/ Positional week weight (hours) Model A Model B 1 2 3 4 0.2 0.4 0.7 0.1 0.3 0.1 0.32 5 6 7 8 0.6 0.26 9 1.2.2. Design an assembly line with the minimum number of workstations and allocate work elements to stations ACCORDING TO THEIR POSITIONAL WEIGHTS if the available time per week is 480 minutes (cycle time) Show all your calculations, including the cumulative station times and the unassigned station time (9)