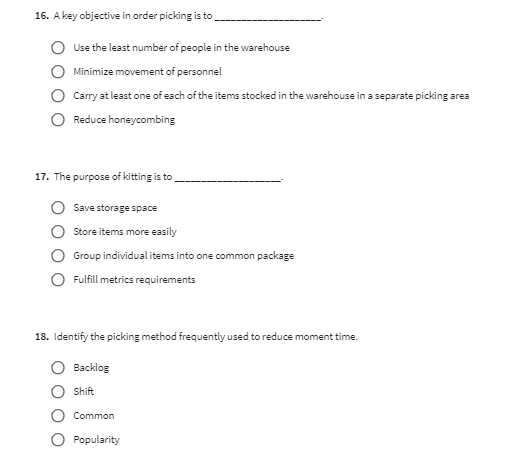

Question: 16. A key objective in order picking is to Use the least number of people in the warehouse Minimize movement of personnel Carry at least

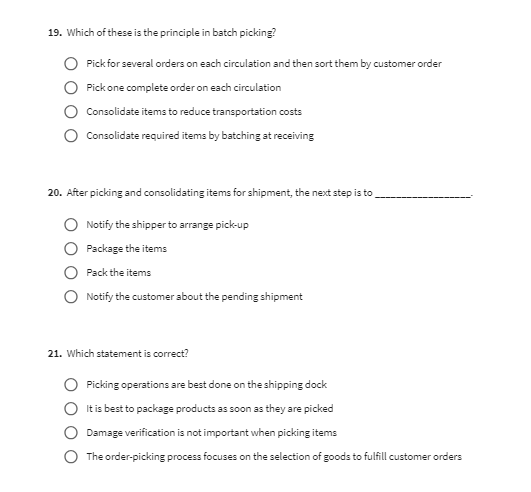

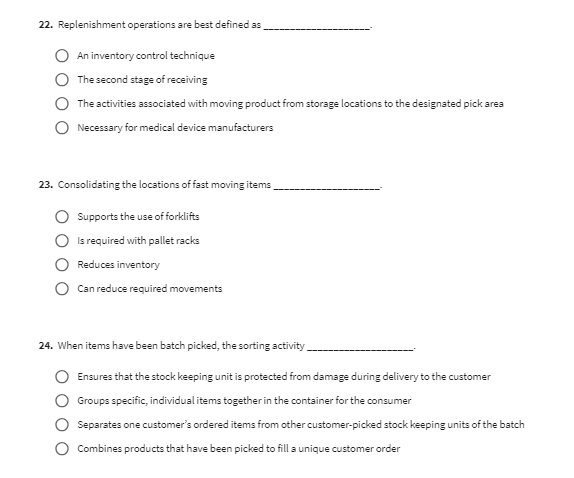

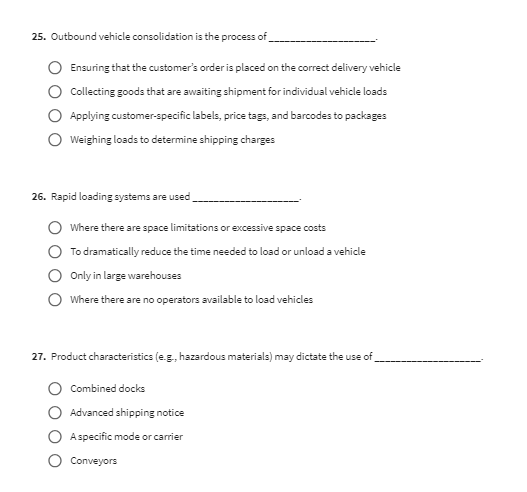

16. A key objective in order picking is to Use the least number of people in the warehouse Minimize movement of personnel Carry at least one of each of the items stocked in the warehouse in a separate picking area Reduce honeycombing 17. The purpose of kitting is to Save storage space Store items more easily Group individual items into one common package Fulfill metrics requirements 18. Identify the picking method frequently used to reduce moment time. Backlog Shift Common Popularity 19. Which of these is the principle in batch picking? Pick for several orders on each circulation and then sort them by customer order Pick one complete order on each circulation Consolidate items to reduce transportation costs Consolidate required items by batching at receiving 20. After picking and consolidating items for shipment, the next step is to Notify the shipper to arrange pick-up Package the items Pack the items Notify the customer about the pending shipment 21. Which statement is correct? Picking operations are best done on the shipping dock It is best to package products as soon as they are picked Damage verification is not important when picking items The order-picking process focuses on the selection of goods to fulfill customer orders 22. Replenishment operations are best defined as An inventory control technique The second stage of receiving The activities associated with moving product from storage locations to the designated pick area Necessary for medical device manufacturers 23. Consolidating the locations of fast moving items Supports the use of forklifts Is required with pallet racks Reduces inventory Can reduce required movements 24. When items have been batch picked, the sorting activity Ensures that the stock keeping unit is protected from damage during delivery to the customer Groups specific, individual items together in the container for the consumer Separates one customer's ordered items from other customer-picked stock keeping units of the batch Combines products that have been picked to fill a unique customer order 25. Outbound vehicle consolidation is the process of Ensuring that the customer's order is placed on the correct delivery vehicle Collecting goods that are awaiting shipment for individual vehicle loads Applying customer-specific labels, price tags, and barcodes to packages Weighing loads to determine shipping charges 26. Rapid loading systems are used Where there are space limitations or excessive space costs To dramatically reduce the time needed to load or unload a vehicle Only in large warehouses Where there are no operators available to load vehicles 27. Product characteristics (e.g., hazardous materials) may dictate the use of Combined docks Advanced shipping notice A specific mode or carrier Conveyors

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts