Question: (16 pts) Dimethyl Ether (DME) production process. Supporting information describing this process and a preliminary process flow diagram (PFD) and associated stream and equipment tables

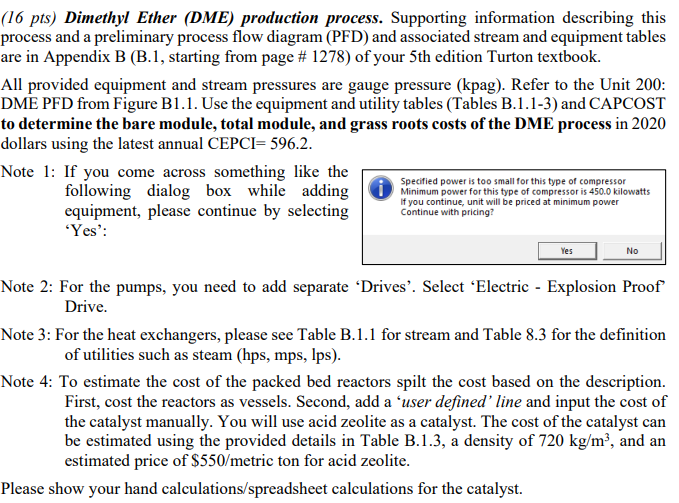

(16 pts) Dimethyl Ether (DME) production process. Supporting information describing this process and a preliminary process flow diagram (PFD) and associated stream and equipment tables are in Appendix B (B.1, starting from page \# 1278) of your 5th edition Turton textbook. All provided equipment and stream pressures are gauge pressure (kpag). Refer to the Unit 200: DME PFD from Figure B1.1. Use the equipment and utility tables (Tables B.1.1-3) and CAPCOST to determine the bare module, total module, and grass roots costs of the DME process in 2020 dollars using the latest annual CEPCI=596.2. Note 1: If you come across something like the following dialog box while adding equipment, please continue by selecting 'Yes': Note 2: For the pumps, you need to add separate 'Drives'. Select 'Electric - Explosion Proof' Drive. Note 3: For the heat exchangers, please see Table B.1.1 for stream and Table 8.3 for the definition of utilities such as steam (hps, mps, lps). Note 4: To estimate the cost of the packed bed reactors spilt the cost based on the description. First, cost the reactors as vessels. Second, add a 'user defined' line and input the cost of the catalyst manually. You will use acid zeolite as a catalyst. The cost of the catalyst can be estimated using the provided details in Table B.1.3, a density of 720kg/m3, and an estimated price of $550/ metric ton for acid zeolite

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts