Question: 2. Total solidification time TST is: a. time required for casting to solidify after pouring b. time required to cool to foom temperature after solidification

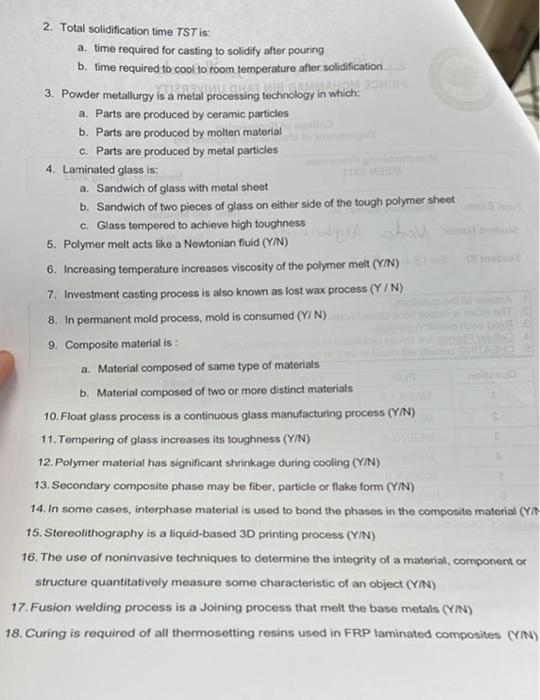

2. Total solidification time TST is: a. time required for casting to solidify after pouring b. time required to cool to foom temperature after solidification 3. Powder metallurgy is a metal processing technology in which: a. Parts are produced by ceramic particles b. Parts are produced by molten material c. Parts are produced by metal particles 4. Laminated glass is: a. Sandwich of glass with metal sheet b. Sandwich of two pieces of glass on either side of the tough polymer sheet c. Glass tompered to achiove high toughness 5. Polymer melt acts like a Newtonian fluid (Y/N) 6. Increasing temperature increases viscosity of the polymer melt (Y/N) 7. Investment casting process is also known as lost wax process ( Y/N ) 8. In permanent mold process, mold is consumed (Y/N) 9. Composite material is : a. Material composed of same type of materials b. Material composed of two or more distinct materials 10. Float glass process is a continuous glass manufacturing process (Y/N) 11. Tempering of glass increases its toughness (Y/N) 12. Polymer material has significant shrinkage during cooling (Y/N) 13. Secondary composite phase may be fiber, particle or flake form (Y/N) 14. In some cases, interphase material is used to bond the phases in the composite material (Yit 15. Stereolithography is a liquid-based 3D printing process (Y/N) 16. The use of noninvasive techniques to determine the integrity of a material, component or structure quantitatively measure some characteristic of an object (Y/N) 17. Fusion welding process is a Joining process that melt the base metals (YIN) 18. Curing is required of all thermosetting resins used in FRP laminated composites (YN)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts