Question: 2MOVE LLC CASE SCENARIO: Megan has set up a new company called 2MOVE which designed a cost-effective smart balancing electric skateboard (see pictures) based on

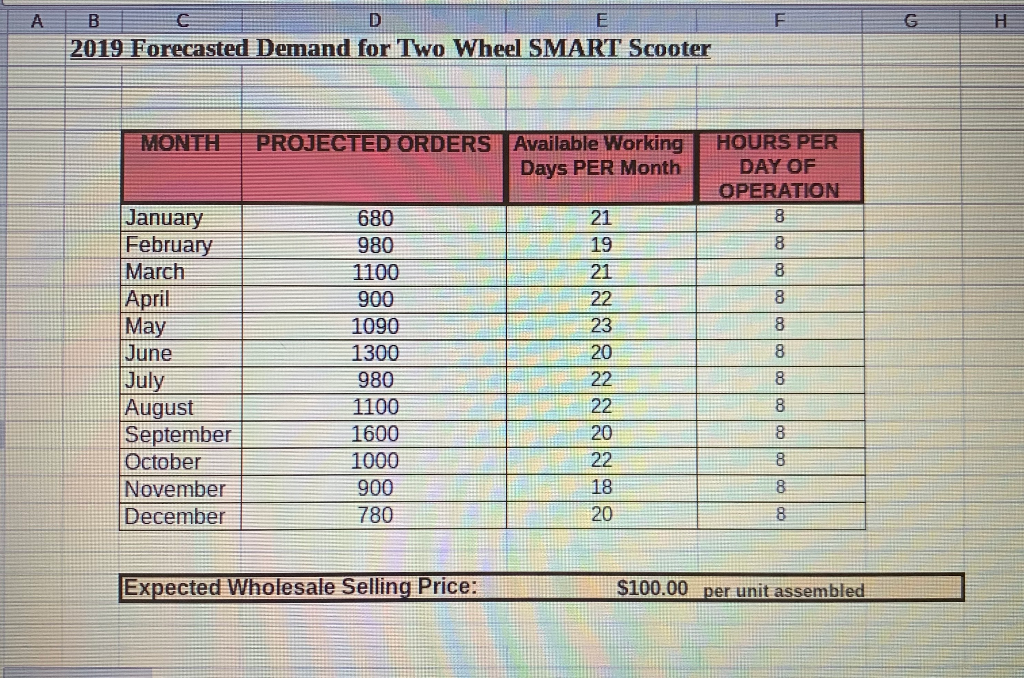

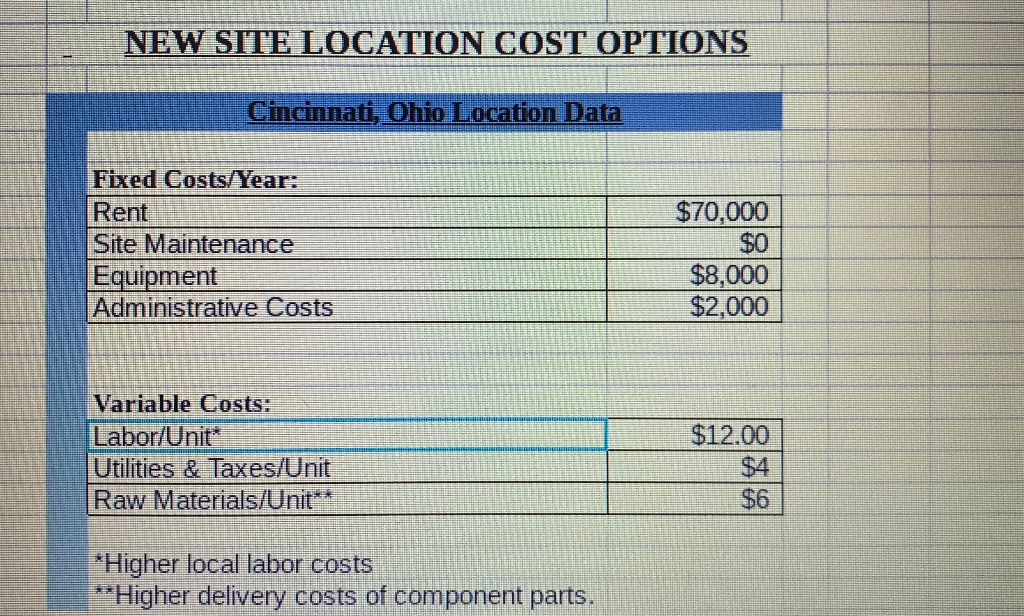

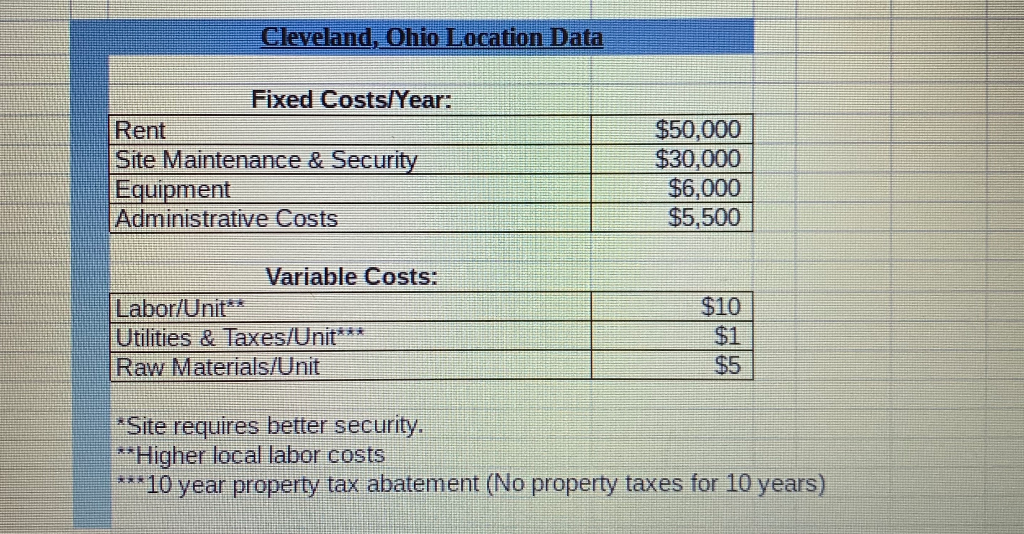

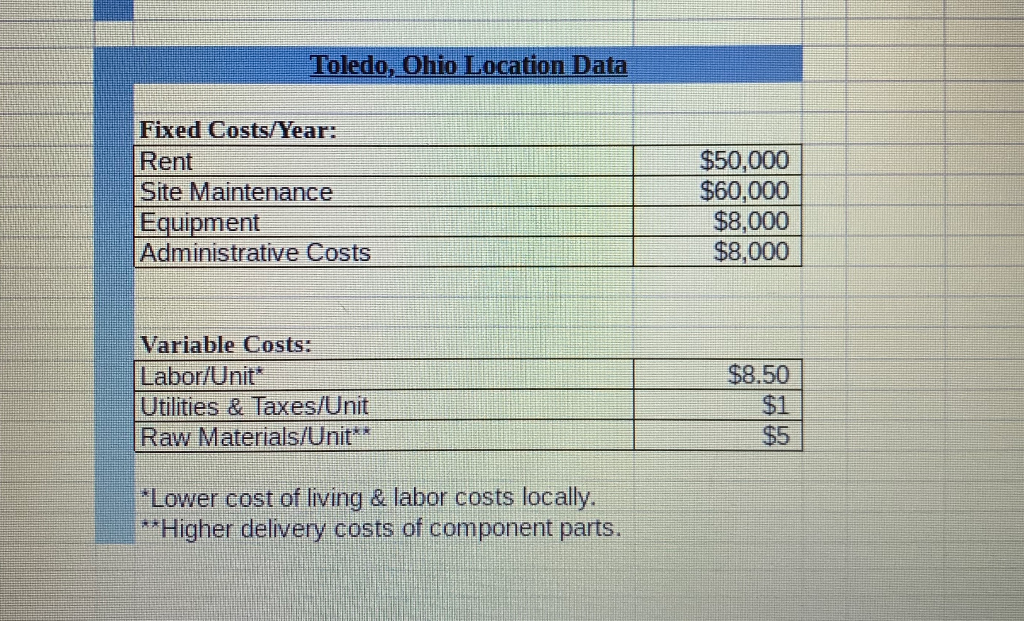

2MOVE LLC CASE SCENARIO: Megan has set up a new company called 2MOVE which designed a cost-effective smart balancing electric skateboard (see pictures) based on the Segway concept. She wants to move to full production and has investigated options to set up an assembly facility at one of three possible sites. Megan plans to be at full operation by January 2019 to meet back to school and Christmas orders for next year. She has secured contracts with 4 major retailers and developed a monthly forecast based off her contracts. She also has developed the assembly process and secured suppliers for all the component parts. She plans to run the operation 8 hours per day during weekdays. Megan needs help in several operational areas to make the best decisions:

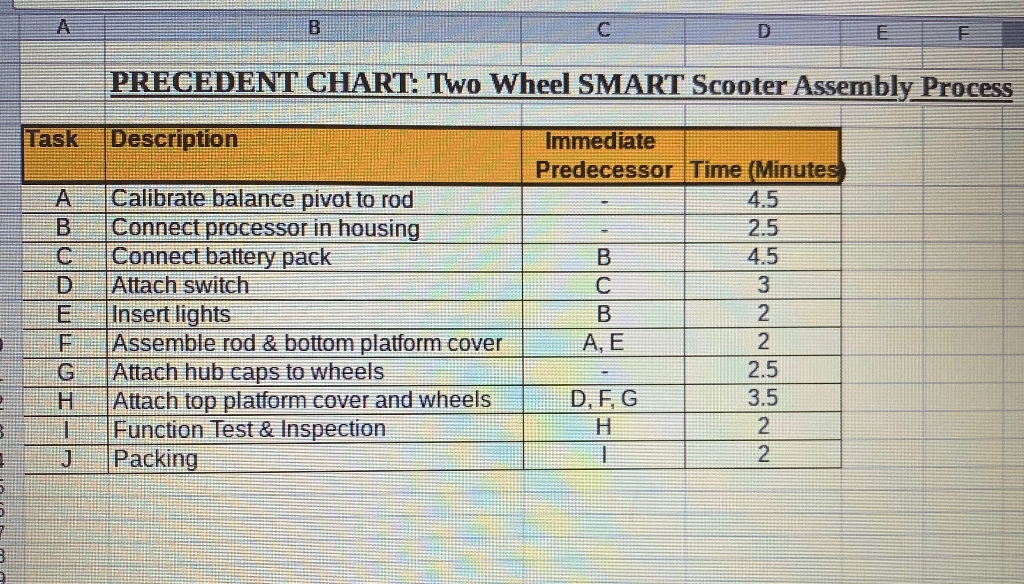

LINE BALANCING & WORK STATION EFFICIENCY: Based on the precedent chart for the new assembly process:

o What is the Process Cycle Time of the overall system? (Hint: Sum of all task times)

o What is her bottleneck? o What is her demands Takt Time?

o How many work stations/employees will be needed if the process operates 8 hours per day based on the available weekdays per month?

o How should the tasks be organized to: Minimize idle time Not violate the precedent chart

o Megan would like to see a visual chart showing the layout of work stations and task assignments.

o What is her idle time & assembly efficiency? o What is her overall station bottleneck time after line balancing?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts