Question: 3 . ( ( mathbf { 1 8 } ) points ) The electric drill shown below is powered by an electric

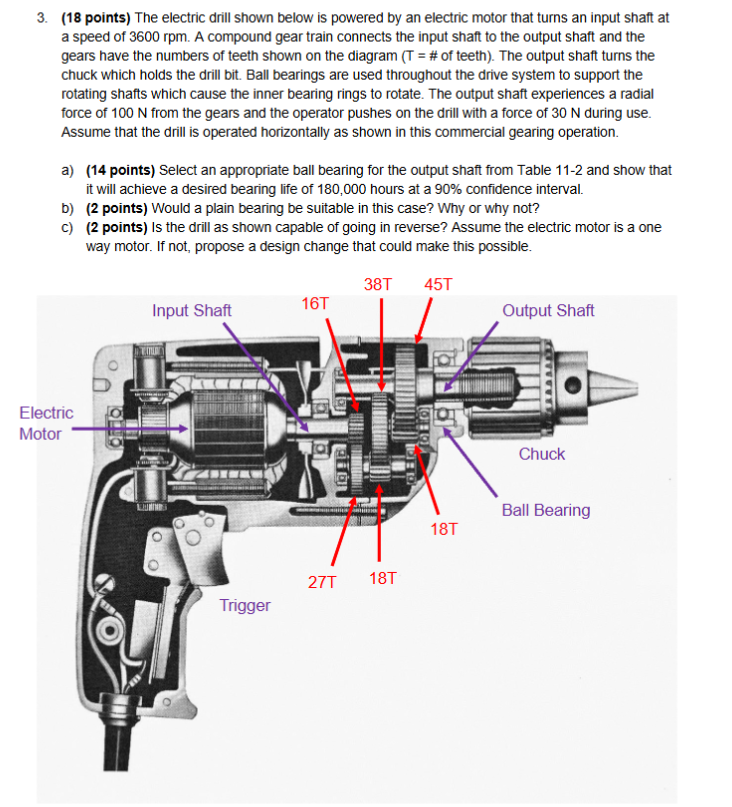

mathbf points The electric drill shown below is powered by an electric motor that turns an input shaft at a speed of rpm A compound gear train connects the input shaft to the output shaft and the gears have the numbers of teeth shown on the diagram mathrmT# of teeth The output shaft turns the chuck which holds the drill bit. Ball bearings are used throughout the drive system to support the rotating shafts which cause the inner bearing rings to rotate. The output shaft experiences a radial force of N from the gears and the operator pushes on the drill with a force of N during use. Assume that the drill is operated horizontally as shown in this commercial gearing operation.

a points Select an appropriate ball bearing for the output shaft from Table and show that it will achieve a desired bearing life of hours at a confidence interval.

b points Would a plain bearing be suitable in this case? Why or why not?

c points Is the drill as shown capable of going in reverse? Assume the electric motor is a one way motor. If not, propose a design change that could make this possible.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock