Question: 3 . ) Milling. You are going to mill a pocket as shown in the Figure below. You will start with a block of 6

Milling.

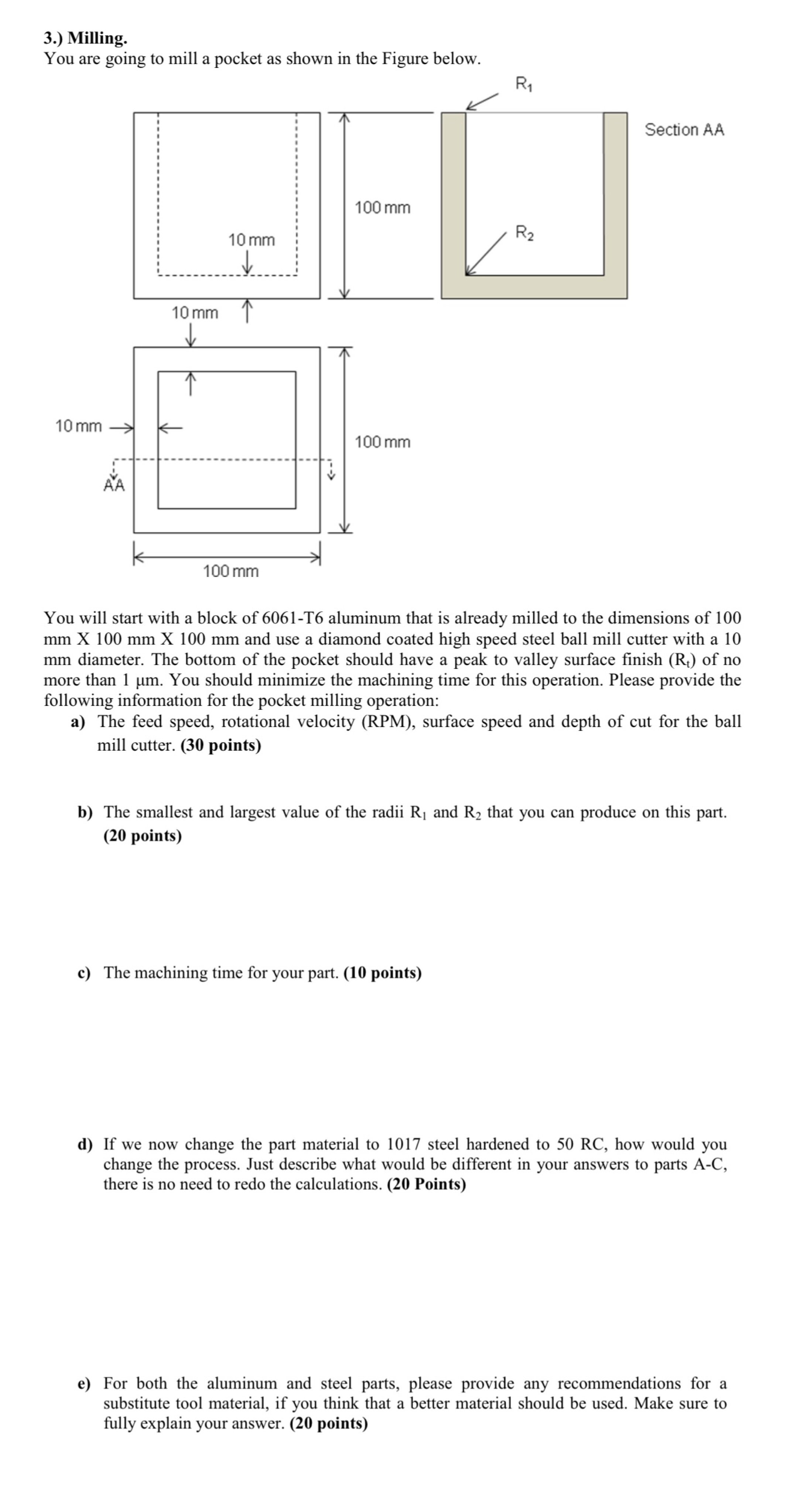

You are going to mill a pocket as shown in the Figure below.

You will start with a block of T aluminum that is already milled to the dimensions of mm X mm X mm and use a diamond coated high speed steel ball mill cutter with a mm diameter. The bottom of the pocket should have a peak to valley surface finish leftmathrmRmathrmtright of no more than mu mathrm~m You should minimize the machining time for this operation. Please provide the following information for the pocket milling operation:

a The feed speed, rotational velocity RPM surface speed and depth of cut for the ball mill cutter. points

b The smallest and largest value of the radii R and R that you can produce on this part. points

c The machining time for your part. points

d If we now change the part material to steel hardened to RC how would you change the process. Just describe what would be different in your answers to parts AC there is no need to redo the calculations. Points

e For both the aluminum and steel parts, please provide any recommendations for a substitute tool material, if you think that a better material should be used. Make sure to fully explain your answer. points

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock