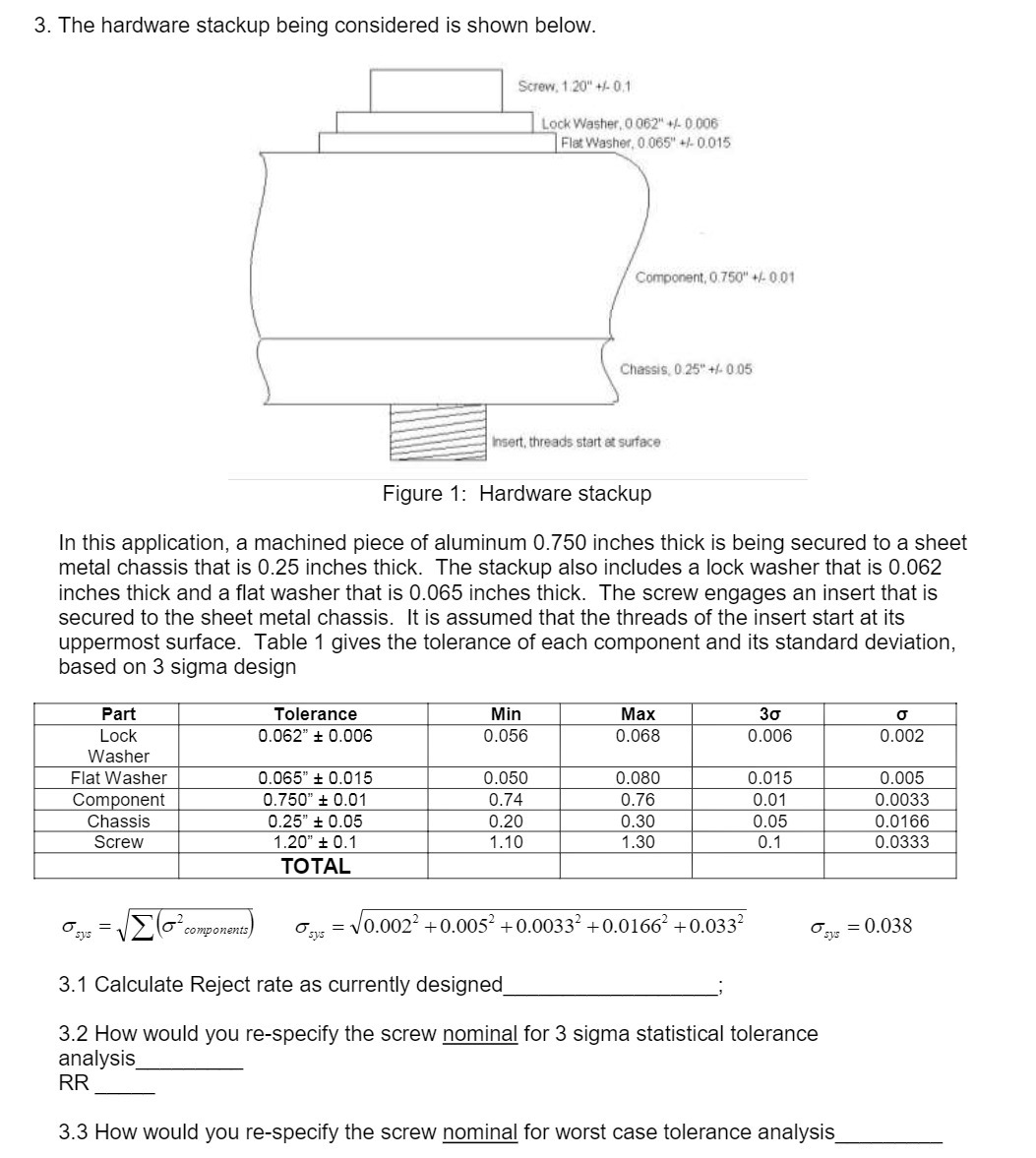

Question: 3. The hardware stackup being considered is shown below. Straw. 1 204 0.1 Lock Washer, 0 C62 +I- 0 ME- Fla! Wash. 0 065 *l-

3. The hardware stackup being considered is shown below. Straw. 1 20"4 0.1 Lock Washer, 0 C62" +I- 0 ME- Fla! Wash\". 0 065\" *l- '10 1'5 Cormorant. 0 750" +I- 0 .01 Figure 1: Hardware stackup In this application, a machined piece of aluminum 0.750 inches thick is being secured to a sheet metal chassis that is 0.25 inches thick. The stackup also includes a lock washer that is 0.062 inches thick and a at washer that is 0.065 inches thick. The screw engages an insert that is secured to the sheet metal chassis. It is assumed that the threads of the insert start at its uppermost surface. Table 1 gives the tolerance of each component and its standard deviation, based on 3 sigma design Lock 0.062" 1 0.006 0.056 0.068 Washer Com conent 0.750" :I: 0.01 0.74 0.76 0.01 0.0033 mum-ima TOTAL 03y. =w/Zlazmmnml cry/.5 = 0.0022 +0.0052 +0.00332 +0.01662 +0.0332 .5595 20.038 3.1 Calculate Reject rate as currently designed ; 3.2 How would you respecify the screw nominal for 3 sigma statistical tolerance analysis RR 3.3 How would you respecify the screw nominal for worst case tolerance analysis

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts