Question: ( 4 0 Points ) A manufacturing process that unintentionally introduces cracks to the surface of a part was used to produce load - bearing

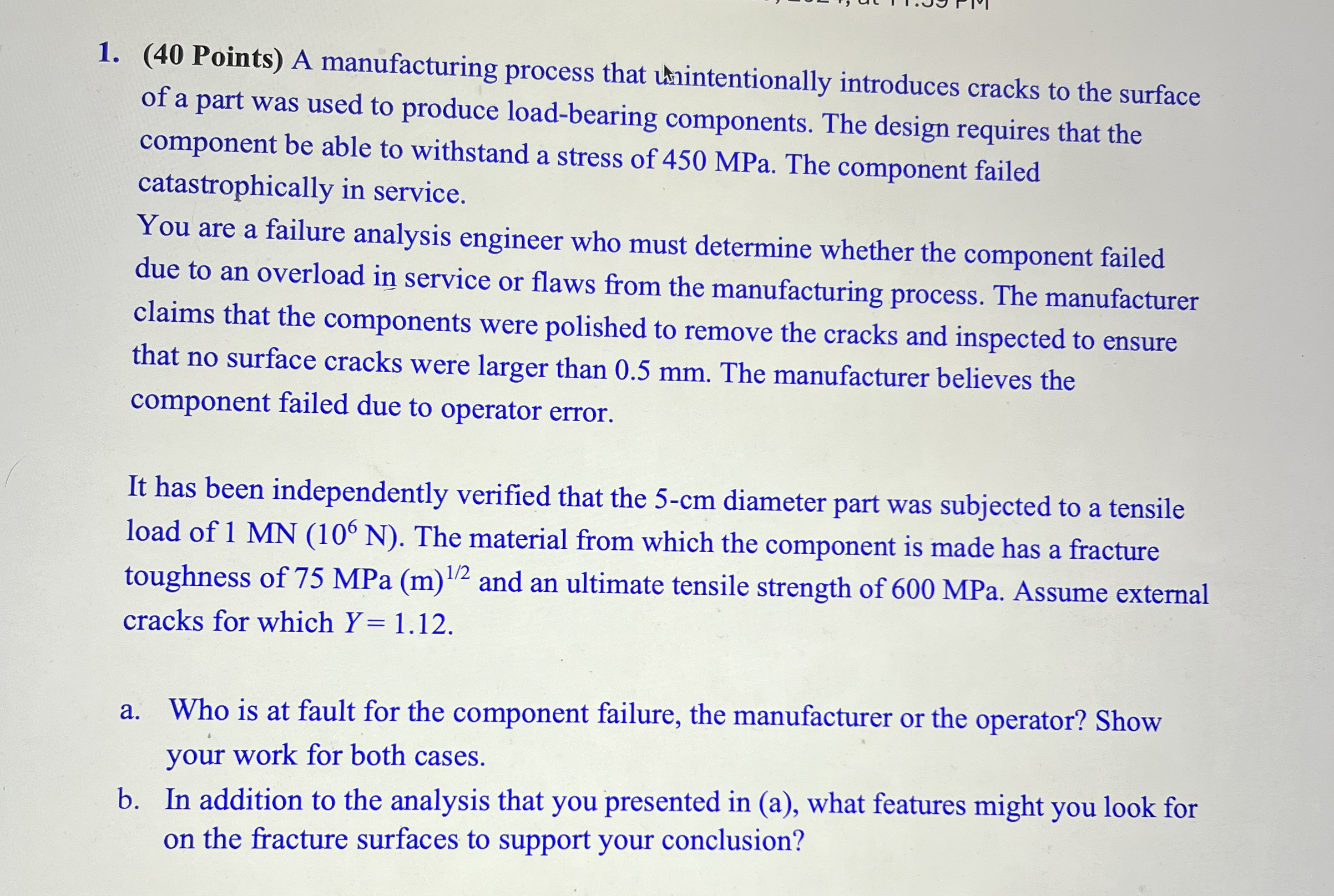

Points A manufacturing process that unintentionally introduces cracks to the surface of a part was used to produce loadbearing components. The design requires that the component be able to withstand a stress of MPa The component failed catastrophically in service.

You are a failure analysis engineer who must determine whether the component failed due to an overload in service or flaws from the manufacturing process. The manufacturer claims that the components were polished to remove the cracks and inspected to ensure that no surface cracks were larger than mm The manufacturer believes the component failed due to operator error.

It has been independently verified that the diameter part was subjected to a tensile load of The material from which the component is made has a fracture toughness of MPa and an ultimate tensile strength of MPa Assume external cracks for which

a Who is at fault for the component failure, the manufacturer or the operator? Show your work for both cases.

b In addition to the analysis that you presented in a what features might you look for on the fracture surfaces to support your conclusion?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock