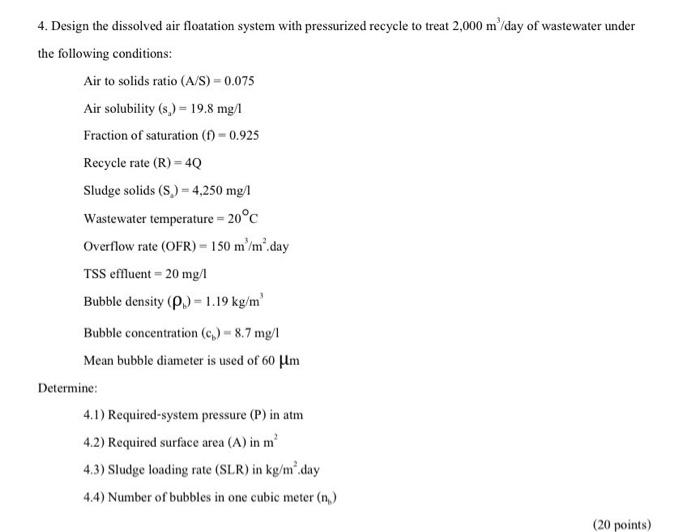

Question: 4. Design the dissolved air floatation system with pressurized recycle to treat 2,000 m /day of wastewater under the following conditions: Air to solids ratio

4. Design the dissolved air floatation system with pressurized recycle to treat 2,000 m /day of wastewater under the following conditions: Air to solids ratio (A/S) = 0.075 Air solubility (s.) 19.8 mg/ Fraction of saturation (1) -0.925 Recycle rate (R) - 40 Sludge solids (S) = 4,250 mg/l Wastewater temperature = 20C Overflow rate (OFR) - 150 mm day TSS effluent = 20 mg/l Bubble density (P) = 1.19 kg/m' Bubble concentration (c)- 8.7 mg/l Mean bubble diameter is used of 60 pm Determine: 4.1) Required-system pressure (P) in atm 4.2) Required surface area (A) in m 4.3) Sludge loading rate (SLR) in kg/m".day 4.4) Number of bubbles in one cubic meter (n) (20 points) 4. Design the dissolved air floatation system with pressurized recycle to treat 2,000 m /day of wastewater under the following conditions: Air to solids ratio (A/S) = 0.075 Air solubility (s.) 19.8 mg/ Fraction of saturation (1) -0.925 Recycle rate (R) - 40 Sludge solids (S) = 4,250 mg/l Wastewater temperature = 20C Overflow rate (OFR) - 150 mm day TSS effluent = 20 mg/l Bubble density (P) = 1.19 kg/m' Bubble concentration (c)- 8.7 mg/l Mean bubble diameter is used of 60 pm Determine: 4.1) Required-system pressure (P) in atm 4.2) Required surface area (A) in m 4.3) Sludge loading rate (SLR) in kg/m".day 4.4) Number of bubbles in one cubic meter (n) (20 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts