Question: 4. In a petroleum refinery unit, low value feedstock consisting of 40% isobutane and 60 % n-butane is converted to high value octanes (C3H18). The

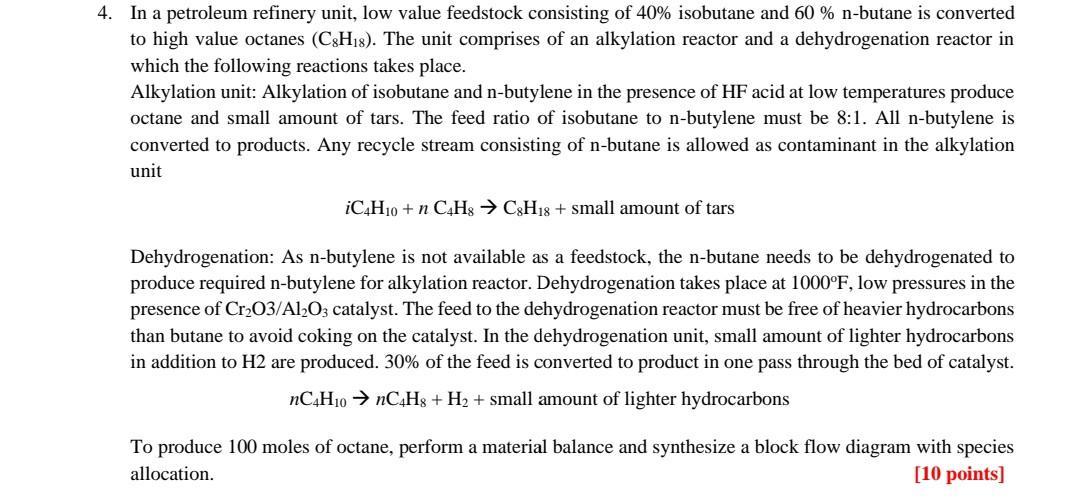

4. In a petroleum refinery unit, low value feedstock consisting of 40% isobutane and 60 % n-butane is converted to high value octanes (C3H18). The unit comprises of an alkylation reactor and a dehydrogenation reactor in which the following reactions takes place. Alkylation unit: Alkylation of isobutane and n-butylene in the presence of HF acid at low temperatures produce octane and small amount of tars. The feed ratio of isobutane to n-butylene must be 8:1. All n-butylene is converted to products. Any recycle stream consisting of n-butane is allowed as contaminant in the alkylation unit iC4H10 + n C.Hg C3H18 + small amount of tars Dehydrogenation: As n-butylene is not available as a feedstock, the n-butane needs to be dehydrogenated to produce required n-butylene for alkylation reactor. Dehydrogenation takes place at 1000F, low pressures in the presence of Cr2O3/Al2O3 catalyst. The feed to the dehydrogenation reactor must be free of heavier hydrocarbons than butane to avoid coking on the catalyst. In the dehydrogenation unit, small amount of lighter hydrocarbons in addition to H2 are produced. 30% of the feed is converted to product in one pass through the bed of catalyst. nC4H10 nC.Hg + H2 + small amount of lighter hydrocarbons To produce 100 moles of octane, perform a material balance and synthesize a block flow diagram with species a allocation. [10 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts