Question: 4 The following questions involve analyzing a manufacturing process with multiple work - stations, each with specific processing times, to determine the bottleneck capacity and

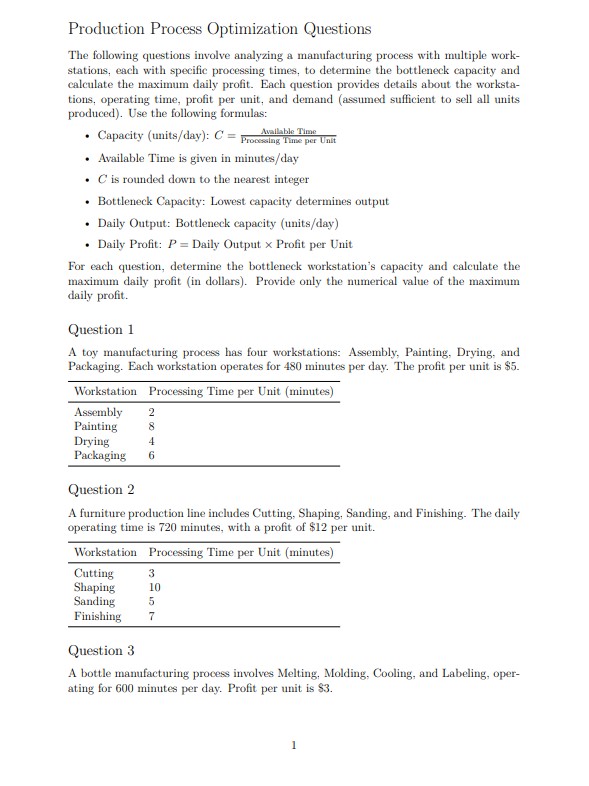

The following questions involve analyzing a manufacturing process with multiple work

stations, each with specific processing times, to determine the bottleneck capacity and

calculate the maximum daily profit. Each question provides details about the worksta

tions, operating time, profit per unit, and demand assumed sufficient to sell all units

produced Use the following formulas:

Capacity unitsday: C Avallable Time Procossing Time per Unit

Available Time is given in minutesday

C is rounded down to the nearest integer

Bottleneck Capacity: Lowest capacity determines output

Daily Output: Bottleneck capacity unitsday

Daily Profit: P Daily Output xx Profit per Unit

For each question, determine the bottleneck workstation's capacity and calculate the

maximum daily profit in dollars Provide only the numerical value of the maximum

daily profit.

Question

A toy manufacturing process has four workstations: Assembly, Painting, Drying, and

Packaging. Each workstation operates for minutes per day. The profit per unit is $

Question

A furniture production line includes Cutting, Shaping, Sanding, and Finishing. The daily

operating time is minutes, with a profit of $ per unit.

Question

A bottle manufacturing process involves Melting, Molding, Cooling, and Labeling, oper

ating for minutes per day. Profit per unit is $

Question

A circuit board production has Solder Paste Application, Component Placement, Reflow

Soldering, and Inspection. Operating time is minutes per day, with a profit of $

per unit.

Question

A textile process includes Spinning, Weaving, Dyeing, and Cutting, with minutes of

daily operation. Profit per unit is $

Question

A food packaging line has Mixing, Filling, Sealing, and Boxing, operating for minutes

per day. Profit per unit is $

Question

A metal fabrication process includes Cutting, Bending, Welding, and Polishing, with

minutes of operation daily. Profit per unit is $

Question

A glassware production line has Forming, Annealing, Inspecting, and Packing, operating

for minutes per day. Profit per unit is $

Question

A paper product process includes Pulping, Pressing, Drying, and Cutting, with

minutes of daily operation. Profit per unit is $

Question

A ceramic tile production has Mixing, Pressing, Glazing, and Firing, operating for

minutes per day. Profit per unit is $

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock