Question: Problem 1 : Electronics Manufacturing Line A manufacturing process produces electronic components through four sequential workstations: Soldering, Testing, Packaging, and Labeling. Each workstation has a

Problem

: Electronics Manufacturing Line

A manufacturing process produces electronic components through four sequential workstations: Soldering, Testing, Packaging, and Labeling. Each workstation has a specific processing time per unit and operates for

day. Due market demand, the goal maximize daily output while respecting capacity constraints. The process has a bottleneck that the total number units produced daily. The profit per unit

$

the objective calculate the maximum daily profit based the bottleneck's capacity.

Process Details:

Workstation: Processes

every

Workstation: Processes

every

Workstation: Processes

every

Workstation: Processes

every

Time:

per day

all workstations operate simultaneously but are constrained the bottleneck

:

$

unit produced and sold.

: Assume demand sufficient sell all units produced.

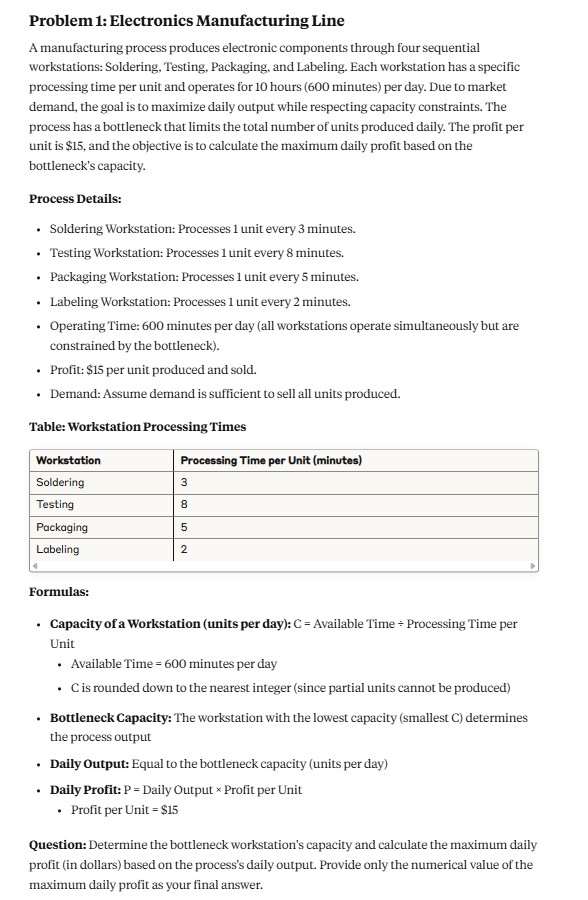

Table: Workstation Processing Times

Formulas:

a Workstation

units per day

:

mathrm

Time

div

Time per Unit

Time

per day

rounded down the nearest integer

since partial units cannot produced

Capacity: The workstation with the lowest capacity

smallest

the process output

Output: Equal the bottleneck capacity

units per day

Profit:

Output

times

per Unit

per Unit

$

Question: Determine the bottleneck workstation's capacity and calculate the maximum daily profit

dollars

the process's daily output. Provide only the numerical value the maximum daily profit your final answer.

Problem : Textile Production Process

A textile manufacturing process produces fabric through three sequential workstations:

Weaving, Dyeing, and Quality Control. Each workstation has a specific processing time per

unit and operates for hours minutes per day. Due market demand, the goal

maximize daily output while respecting capacity constraints. The process has a bottleneck

that the total number units produced daily. The profit per unit $ and the

objective calculate the maximum daily profit based the bottleneck's capacity.

Process Details:

Weaving Workstation: Processes unit every minutes.

Dyeing Workstation: Processes unit every minutes.

Quality Control Workstation: Processes unit every minutes.

Operating Time: minutes per day workstations operate simultaneously but are

constrained the bottleneck

Profit: $ per unit produced and sold.

Demand: Assume demand sufficient sell all units prod A food processing facility produces packaged meals throu

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock