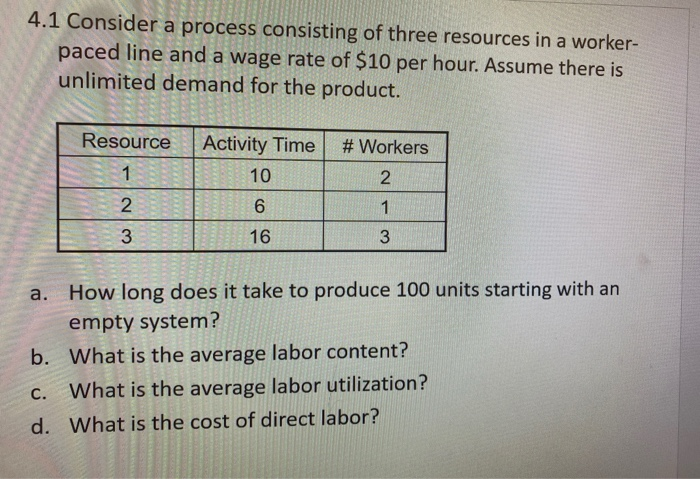

Question: 4.1 Consider a process consisting of three resources in a worker- paced line and a wage rate of $10 per hour. Assume there is unlimited

4.1 Consider a process consisting of three resources in a worker- paced line and a wage rate of $10 per hour. Assume there is unlimited demand for the product. Resource 1 2 3 Activity Time #Workers | 102 6 1 16 a. How long does it take to produce 100 units starting with an empty system? b. What is the average labor content? c. What is the average labor utilization? d. What is the cost of direct labor? Your idea is to bake fresh cookies to order, using any combination of ingredients that the buyer wants. The cookies will be ready for pickup at your apartment within an hour. Several factors will set you apart from competing products such as store-bought cookies. First, your cookies will be completely fresh. You will not bake any cookies before receiving the order, nor will you mix any dough before receiving an order. If you get an order for one dozen cookies of any type, you would not make the two or three dozen quantity of dough and assume that an order later in the evening would require that work-in-process inventory. These simple rules guarantee that the buyer will be getting cookies that are literally hot out of the oven made from the freshest dough possible. Second, like The Marble Slab, you will have a variety of ingredients available to add to the basic dough, including chocolate chips, M&M's, chopped Heath bars, coconut, walnuts, jalapenos, and cat hair. Buyers will telephone in their orders and specify which of these ingredients they want in their cookies. You guarantee completely fresh cookies. In short, you will have the freshest, most exotic cookies anywhere, available right on campus. exotic cook The Production Process Baking cookies is simple: mix all the ingredients in a food processor, spoon out the cookie dough onto a tray, put the cookies into the oven; bake them; take the tray of cookies out of the oven; let the cookies cool; and, finally, take the cookies off the tray and carefully pack them in a box. You and your roommate already own all the necessary capital equipment: one food processor, a dozen cookie trays and a dozen spoons. Your apartment has a small oven that will hold one tray at a time. The apartment pays for all the electricity. The variable costs, therefore, are merely the cost of the ingredients (estimated to be $1.00/dozen), the cost of the box in which the cookies are packed (50.10 per box, each box holds a dozen cookies), and your time. A detailed examination of the production process, which specifies how long each of the steps will take, follows. The first step is to take an order, which your roommate has figured out how to do quickly and with 100% accuracy. (Actually, you and your roommate devised a method using an app to accept orders and to inform customers when their orders will be ready for pickup. Because this runs automatically, it does not take any of your time.) Therefore, this step will be ignored in further analysis You and your roommate have timed the necessary physical operations. The first physical production step is to wash out the mixing bowl from the previous batch, add all of the ingredients, and mix them in your food processor. The mixing bowls hold ingredients for up to 3 dozen cookies You then dish up the cookies, one dozen at a time, onto a cookie tray. These activities take six minutes for the washing and mixing steps, regardless of how many cookies are being made in the batch. That is, to mix enough dough and ingredients for two dozen cookies takes the same six minutes as one dozen cookies. However, dishing up the cookies onto the tray takes two minutes per tray. The next step, performed by your roommate, is to put the cookies in the oven and set the thermostat and timer, which takes about one minute. The cookies bake for the next nine minutes. So total baking time is 10 minutes, during the first minute of which your roommate is busy setting the oven and timer. Because the oven only holds one tray, a second dozen takes an additional 10 minutes to bake. Your roommate also performs the last steps of the process by first removing the cookies from the oven and putting them aside to cool for 5 minutes, then carefully packing them in a box and accepting payment. Removing the cookies from the oven takes only a negligible amount of time, but it must be done promptly. It takes two minutes to pack each dozen and about one minute to accept payment for the order. That is the process for producing cookies by the dozen by the Bronco Bakery. As experienced bakers know, a few simplifications were made in the actual cookie production process. For example, the first batch of cookies for the night requires preheating the oven but for this analysis we can assume the oven is heated and ready to go when your shift begins. Key Questions to Answer Before You Launch the Business For all these questions show your calculations or method of analysis and label all units 1. 2. 3. How long will it take you to fill a rush order at the beginning of an evening? How many orders for one dozen cookies can you fill in a night, assuming you are open four hours each night? How much of your own and your roommate's valuable time will it take to fill orders for one two and three dozen? Assume that an order for two or three dozen is all of the same type of cookie. Because your baking trays can hold exactly one dozen cookies, you will produce and sell cookies by the dozen. Should you give any discount for people who order two dozen cookies three dozen cookies, or more of the same type? If so, how much? What happens if you are trying to do this by yourself without a roommate? Can you achieve the flow rate you achieved in 2 Your old oven breaks and the campus maintenance supervisor decides to install a new oven that can hold two trays at a time. What is the effect of the new oven on your answers to and #27 Your product must be made to order because each order is potentially unique. If you decide to sell standard cookies instead, name three specific changes should you make in the production system and/or product design. Provide a prioritized list indicating the specific change you would make in the original process and the net effect of implementing the change