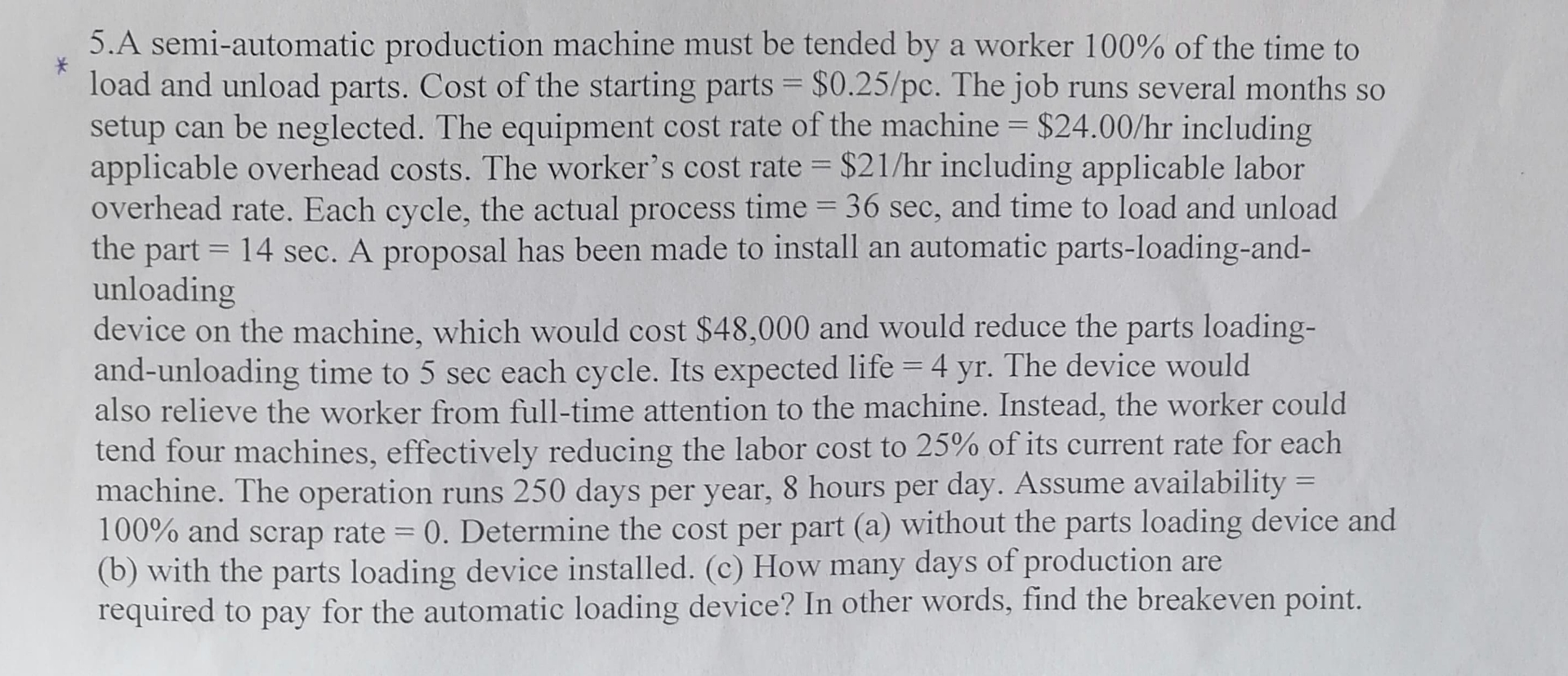

Question: 5 . A semi - automatic production machine must be tended by a worker 1 0 0 % of the time to load and unload

A semiautomatic production machine must be tended by a worker of the time to

load and unload parts. Cost of the starting parts $ The job runs several months so

setup can be neglected. The equipment cost rate of the machine $ including

applicable overhead costs. The worker's cost rate $ including applicable labor

overhead rate. Each cycle, the actual process time and time to load and unload

the part A proposal has been made to install an automatic partsloadingand

unloading

device on the machine, which would cost $ and would reduce the parts loading

andunloading time to sec each cycle. Its expected life The device would

also relieve the worker from fulltime attention to the machine. Instead, the worker could

tend four machines, effectively reducing the labor cost to of its current rate for each

machine. The operation runs days per year, hours per day. Assume availability

and scrap rate Determine the cost per part a without the parts loading device and

b with the parts loading device installed. c How many days of production are

required to pay for the automatic loading device? In other words, find the breakeven point.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock