Question: 6 . 1 3 Case study 4 : Supplier Selection and Order Allocation In this case study, you will solve a supplier order allocation problem

Case study : Supplier Selection and Order Allocation

In this case study, you will solve a supplier order allocation problem with two products, two buyers, and two suppliers. The problem has three conflicting criteria, namely, total cost, leadtime, and quality measured by rejects All three objectives have to be minimized.

Minimize total cost, which consists of fixed cost and the variable cost. Fixed cost is a onetime cost that is incurred if a supplier is used irrespective of the number of units bought from that supplier.

Minimize the weighted average leadtime.

Supply Chain Engineering: Models and Applications

Minimize the weighted average quality.

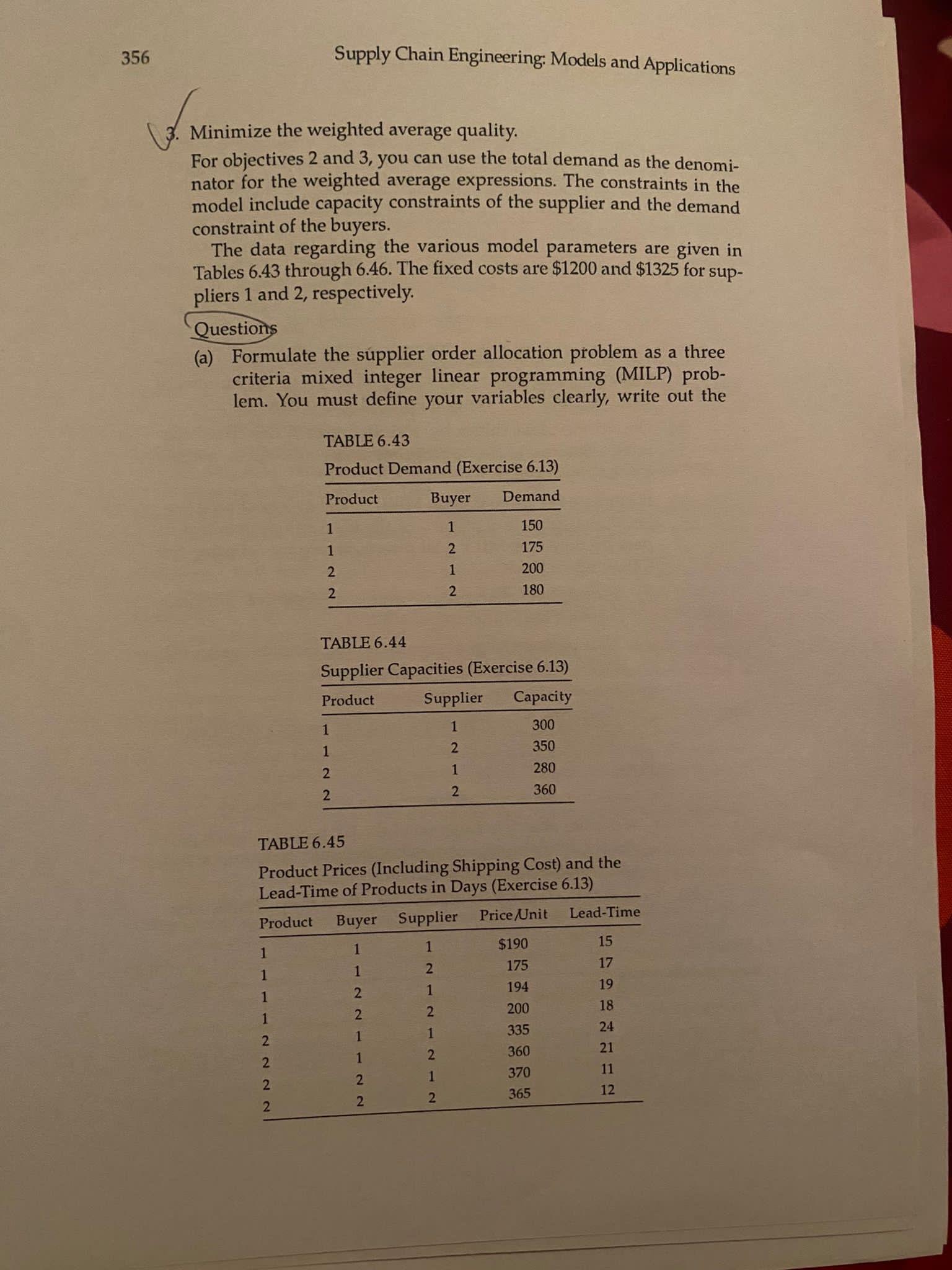

For objectives and you can use the total demand as the denominator for the weighted average expressions. The constraints in the model include capacity constraints of the supplier and the demand constraint of the buyers.

The data regarding the various model parameters are given in Tables through The fixed costs are $ and $ for suppliers and respectively.

Questions

a Formulate the supplier order allocation problem as a three criteria mixed integer linear programming MILP problem. You must define your variables clearly, write out the

TABLE

Product Demand Exercise

tableProductBuyer,Demand

TABLE

Supplier Capacities Exercise

tableProductSupplier,Capacity

TABLE

Product Prices Including Shipping Cost and the LeadTime of Products in Days Exercise

tableLeadTime of Products in Days Exercise ProductBuyer,Supplier,Price Nnit,LeadTime$

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock