Question: 6. Direct Time Study Method In order to implement the direct time study (DTS) the work study engineer should follow the following procedures: 1. Define

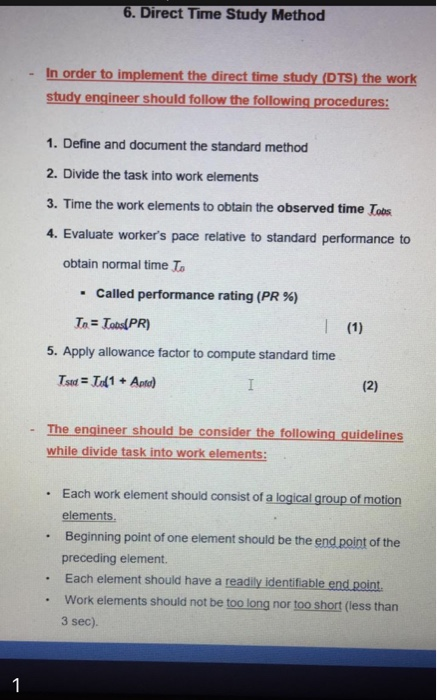

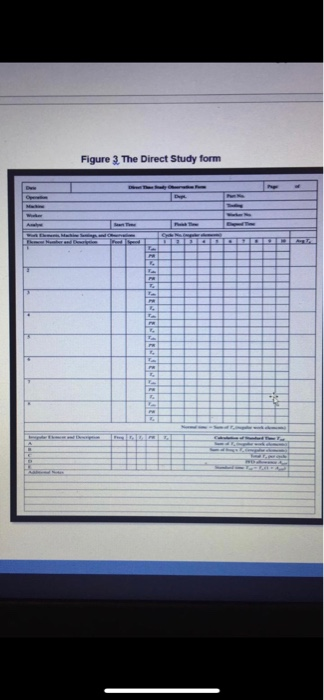

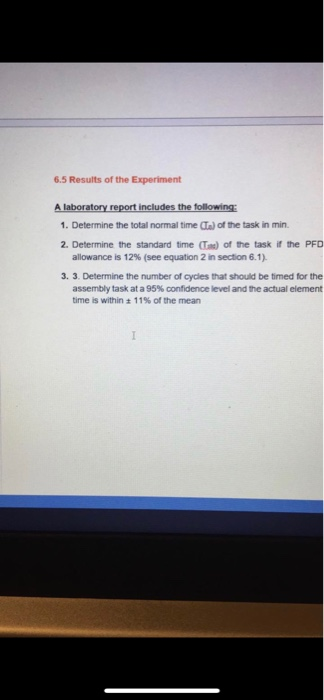

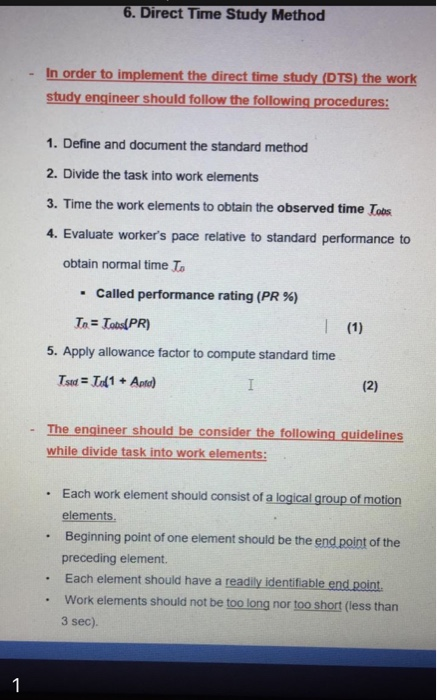

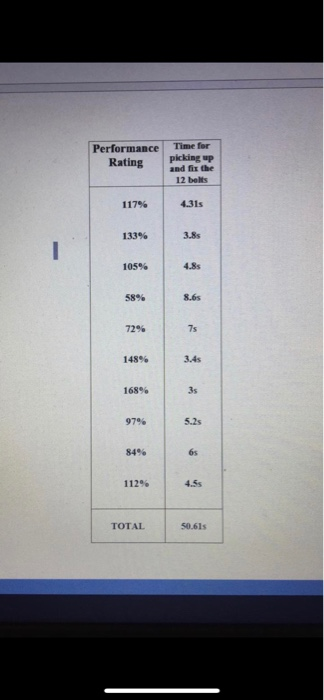

6. Direct Time Study Method In order to implement the direct time study (DTS) the work study engineer should follow the following procedures: 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tous 4. Evaluate worker's pace relative to standard performance to obtain normal time To . Called performance rating (PR %) Ta = Tots(PR) T (1) 5. Apply allowance factor to compute standard time Tsad = To(1 + Apta) The engineer should be consider the following guidelines while divide task into work elements: Each work element should consist of a logical group of motion elements. Beginning point of one element should be the end point of the preceding element. Each element should have a readily identifiable end point. Work elements should not be too long nor too short (less than 3 sec). Separate irregular elements (non-frequent element) from regular elements. Separate manual elements from machine elements. Separate internal elements (during machine work) from external elements 6.4 Experiment Procedures (Cutting saw machine task) 1. Participants are given a brief introduction to the experiment in order to familiarize themselves with the procedure. They are provided with instructions and advised on how to assemble the wooden plates 1. The students need to divide task into work elements. The assembly task includes 12 bolts so; the student should consider each bolt as a one work element (12 work elements). 2. They need to use the form of Direct Time Study (see Figure 3) to record the observation time and performance rating for the task. Also, they require to write all work elements in the form. 3. One student in the group assembles all the components supplied. In one plate assembly the student is required to fix 12 complete bolts sets (consisting of boits, nuts and washers) with different sizes on both upright plates. The student needs pick up the small bolts and nuts in order to fix them and he requires to check the tight quality of the assembly. After that The homework - Microsoft Word MROBAT he needs to pick up the large bolts and nuts and fix them and also, he needs to check it. Finally, the student to needs to lift the plate (assembled object) and put it in other location. 4. The other students record the observation time to complete each work element (fix one bolt) as well as the performance rating for each work element. The performance rating of the student depends on the speed and the quality of assembly task. Therefore, the students require to check the tight quality of the assembly. The student should assign PR = 100% for the normal performance, greater than 100% for the faster and good accuracy performance and lower 100% for the slower student performance and poor accuracy. 5. Each group have to collect the data of observation time and performance rating for each work element from all other class groups and complete these data in cycle columns as illustrated in the form direct time study. 6. Then the students need to compute the normal time for each work element by using the previous equation (1) in section 6.1. After that, they require to add all normal time for all work elements to determine the total normal time for the task Figure 3 The Direct Study form L ess[es ese/[ese Time for picking up and fix the 12 bolts 4.315 TOTAL 50.615 6.5 Results of the Experiment A laboratory report includes the following: 1. Determine the total normal time ) of the task in min 2. Determine the standard time of the task if the PFD allowance is 12% (see equation 2 in section 6.1) 3. 3. Determine the number of cycles that should be timed for the assembly task at a 95% confidence level and the actual element time is within 11% of the mean 6. Direct Time Study Method In order to implement the direct time study (DTS) the work study engineer should follow the following procedures: 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tabs 4. Evaluate worker's pace relative to standard performance to obtain normal time To (1) . Called performance rating (PR %) Ta = Tots(PR) T 5. Apply allowance factor to compute standard time Tsad = T-41 + Aptd) The engineer should be consider the following guidelines while divide task into work elements: Each work element should consist of a logical group of motion elements. Beginning point of one element should be the end point of the preceding element. Each element should have a readily identifiable end point. Work elements should not be too long nor too short (less than 3 sec). Separate irregular elements (non-frequent element) from regular elements. Separate manual elements from machine elements. Separate internal elements (during machine work) from external elements. 6.4 Experiment Procedures (Cutting saw machine task) 1. Participants are given a brief introduction to the experiment in order to familiarize themselves with the procedure. They are. provided with instructions and advised on how to assemble, the wooden plates 1. The students need to divide task into work elements. The assembly task includes 12 bolts so; the student should consider each bolt as a one work element (12 work elements). 2. They need to use the form of Direct Time Study (see Figure 3) to record the observation time and performance rating for the task. Also, they require to write all work elements in the form. 3. One student in the group assembles all the components supplied. In one plate assembly the student is required to fix 12 complete bolts sets (consisting of bolts, nuts and washers) with different sizes on both upright plates. The student needs pick up the small bolts and nuts in order to fix them and he requires to check the tight quality of the assembly. After that Performance Rating Time for picking up and fix the 12 bolts 1179 58% 72% 148% 1689 849 112 TOTAL 50.61s 6. Direct Time Study Method In order to implement the direct time study (DTS) the work study engineer should follow the following procedures: 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tous 4. Evaluate worker's pace relative to standard performance to obtain normal time To . Called performance rating (PR %) Ta = Tots(PR) T (1) 5. Apply allowance factor to compute standard time Tsad = To(1 + Apta) The engineer should be consider the following guidelines while divide task into work elements: Each work element should consist of a logical group of motion elements. Beginning point of one element should be the end point of the preceding element. Each element should have a readily identifiable end point. Work elements should not be too long nor too short (less than 3 sec). Separate irregular elements (non-frequent element) from regular elements. Separate manual elements from machine elements. Separate internal elements (during machine work) from external elements 6.4 Experiment Procedures (Cutting saw machine task) 1. Participants are given a brief introduction to the experiment in order to familiarize themselves with the procedure. They are provided with instructions and advised on how to assemble the wooden plates 1. The students need to divide task into work elements. The assembly task includes 12 bolts so; the student should consider each bolt as a one work element (12 work elements). 2. They need to use the form of Direct Time Study (see Figure 3) to record the observation time and performance rating for the task. Also, they require to write all work elements in the form. 3. One student in the group assembles all the components supplied. In one plate assembly the student is required to fix 12 complete bolts sets (consisting of boits, nuts and washers) with different sizes on both upright plates. The student needs pick up the small bolts and nuts in order to fix them and he requires to check the tight quality of the assembly. After that The homework - Microsoft Word MROBAT he needs to pick up the large bolts and nuts and fix them and also, he needs to check it. Finally, the student to needs to lift the plate (assembled object) and put it in other location. 4. The other students record the observation time to complete each work element (fix one bolt) as well as the performance rating for each work element. The performance rating of the student depends on the speed and the quality of assembly task. Therefore, the students require to check the tight quality of the assembly. The student should assign PR = 100% for the normal performance, greater than 100% for the faster and good accuracy performance and lower 100% for the slower student performance and poor accuracy. 5. Each group have to collect the data of observation time and performance rating for each work element from all other class groups and complete these data in cycle columns as illustrated in the form direct time study. 6. Then the students need to compute the normal time for each work element by using the previous equation (1) in section 6.1. After that, they require to add all normal time for all work elements to determine the total normal time for the task Figure 3 The Direct Study form L ess[es ese/[ese Time for picking up and fix the 12 bolts 4.315 TOTAL 50.615 6.5 Results of the Experiment A laboratory report includes the following: 1. Determine the total normal time ) of the task in min 2. Determine the standard time of the task if the PFD allowance is 12% (see equation 2 in section 6.1) 3. 3. Determine the number of cycles that should be timed for the assembly task at a 95% confidence level and the actual element time is within 11% of the mean 6. Direct Time Study Method In order to implement the direct time study (DTS) the work study engineer should follow the following procedures: 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tabs 4. Evaluate worker's pace relative to standard performance to obtain normal time To (1) . Called performance rating (PR %) Ta = Tots(PR) T 5. Apply allowance factor to compute standard time Tsad = T-41 + Aptd) The engineer should be consider the following guidelines while divide task into work elements: Each work element should consist of a logical group of motion elements. Beginning point of one element should be the end point of the preceding element. Each element should have a readily identifiable end point. Work elements should not be too long nor too short (less than 3 sec). Separate irregular elements (non-frequent element) from regular elements. Separate manual elements from machine elements. Separate internal elements (during machine work) from external elements. 6.4 Experiment Procedures (Cutting saw machine task) 1. Participants are given a brief introduction to the experiment in order to familiarize themselves with the procedure. They are. provided with instructions and advised on how to assemble, the wooden plates 1. The students need to divide task into work elements. The assembly task includes 12 bolts so; the student should consider each bolt as a one work element (12 work elements). 2. They need to use the form of Direct Time Study (see Figure 3) to record the observation time and performance rating for the task. Also, they require to write all work elements in the form. 3. One student in the group assembles all the components supplied. In one plate assembly the student is required to fix 12 complete bolts sets (consisting of bolts, nuts and washers) with different sizes on both upright plates. The student needs pick up the small bolts and nuts in order to fix them and he requires to check the tight quality of the assembly. After that Performance Rating Time for picking up and fix the 12 bolts 1179 58% 72% 148% 1689 849 112 TOTAL 50.61s