Question: 6.8-3. Develop the recycle structure for the gas-phase process that produces acetone from isopropanol (Exercise 54-4). Assume that AH, -25,800 Btu/mol and that the reactor

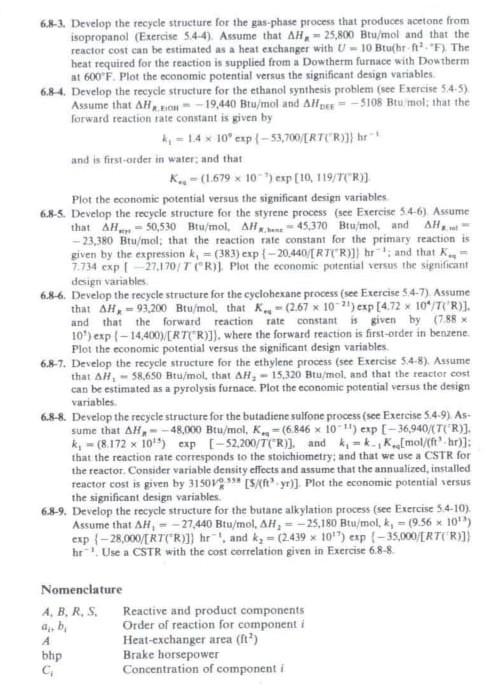

6.8-3. Develop the recycle structure for the gas-phase process that produces acetone from isopropanol (Exercise 54-4). Assume that AH, -25,800 Btu/mol and that the reactor cost can be estimated as a heat exchanger with U-10 Btuht "F). The heat required for the reaction is supplied from a Dowtherm furnace with Dowtherm at 600F. Plot the economic potential versus the significant design variables 6.84. Develop the recycle structure for the ethanol synthesis problem (see Exercise 54-5) Assume that AH .zin -19,440 Btu/mol and Alu- - 5108 Btu mol that the forward reaction rate constant is given by Hi - 1.4 x 10'exp{-53,700/[RTOR)]}hr and is first-order in water and that K.-(1.679 x 10") exp(10. 119/TCR)) Plot the economic potential versus the significant design variables 6.8-5. Develop the recycle structure for the styrene process (see Exercise 54-6). Assume that AH.- 50,530 Btu/mol. AH-45,370 Btu/mol, and AH- - 23,380 Btu/mol; that the reaction rate constant for the primary reaction is given by the expression k, = (383) exp{-20.440[RTUR)]ht, and that - 7.734 exp[-27170/TR] Plot the economic potential versus the significant design variables 6.8-6. Develop the recycle structure for the cyclohexane process (see Exercise 54-7). Assume that a, -93,200 Btu/mol, that K.,- (2.67 x 10-2) exp(4.72 109/TR)). and that the forward reaction rate constant is given by (788 10') exp{-14,400)[RTOR)]). where the forward reaction is first-order in benzene. Plot the economic potential versus the significant design variables. 6.8-7. Develop the recycle structure for the ethylene process (see Exercise 5.4-8). Assume that all, - 58,650 Btu/mol, that AH, - 15.320 Btu/mol, and that the reactor cost can be estimated as a pyrolysis furnace. Plot the economic potential versus the design variables 6.8-8. Develop the recycle structure for the butadiene sulfone process (see Exercise 54.9) As- sume that AM-48,000 Btu/mol, K., -(6.846 10-) exp[-36,940/(T("R)). ki - (8172 x 1015) exp [-52.200/TCR)). and ki-k, K[mol/(fthr)); that the reaction rate corresponds to the stoichiometry, and that we use a CSTR for the reactor. Consider variable density effects and assume that the annualized, installed reactor cost is given by 3150099 [5/(fyr)]. Plot the economic potential versus the significant design variables 6.8-9. Develop the recycle structure for the butane alkylation process (see Exercise 54-10) Assume that AH, = -27,440 Btu/mol, AH, - - 25,180 Btu/mol, k, - (9.56 x 10 exp{-28,000/[RT(R)]] hrs and ke-12439 10') exp(-35,000[RTOR)] hrUse a CSTR with the cost correlation given in Exercise 6.8-8 Nomenclature A, B, R, S, Reactive and product components 4. Order of reaction for componenti Heat-exchanger area (ft) blip Brake horsepower C Concentration of componenti A

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts