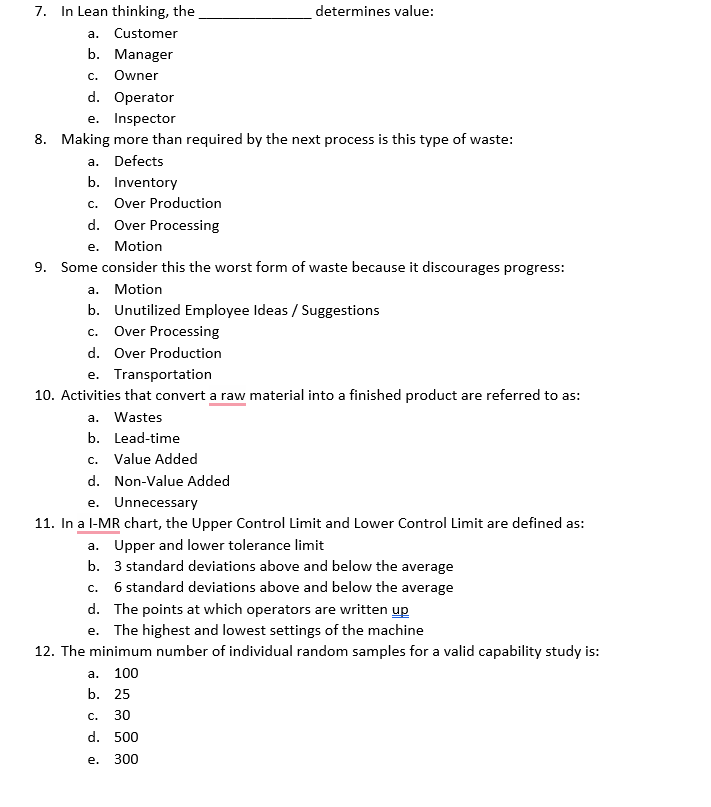

Question: 7. In Lean thinking, the determines value: a. Customer b. Manager c. Owner d. Operator e. Inspector 8. Making more than required by the next

7. In Lean thinking, the determines value: a. Customer b. Manager c. Owner d. Operator e. Inspector 8. Making more than required by the next process is this type of waste: a. Defects b. Inventory c. Over Production d. Over Processing e. Motion 9. Some consider this the worst form of waste because it discourages progress: a. Motion b. Unutilized Employee Ideas / Suggestions c. Over Processing d. Over Production e. Transportation 10. Activities that convert a raw material into a finished product are referred to as: a. Wastes b. Lead-time c. Value Added d. Non-Value Added e. Unnecessary 11. In a I-MR chart, the Upper Control Limit and Lower Control Limit are defined as: a. Upper and lower tolerance limit b. 3 standard deviations above and below the average c. 6 standard deviations above and below the average d. The points at which operators are written u e. The highest and lowest settings of the machine 12. The minimum number of individual random samples for a valid capability study is: a. 100 b. 25 c. 30 d. 500 e. 300

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts