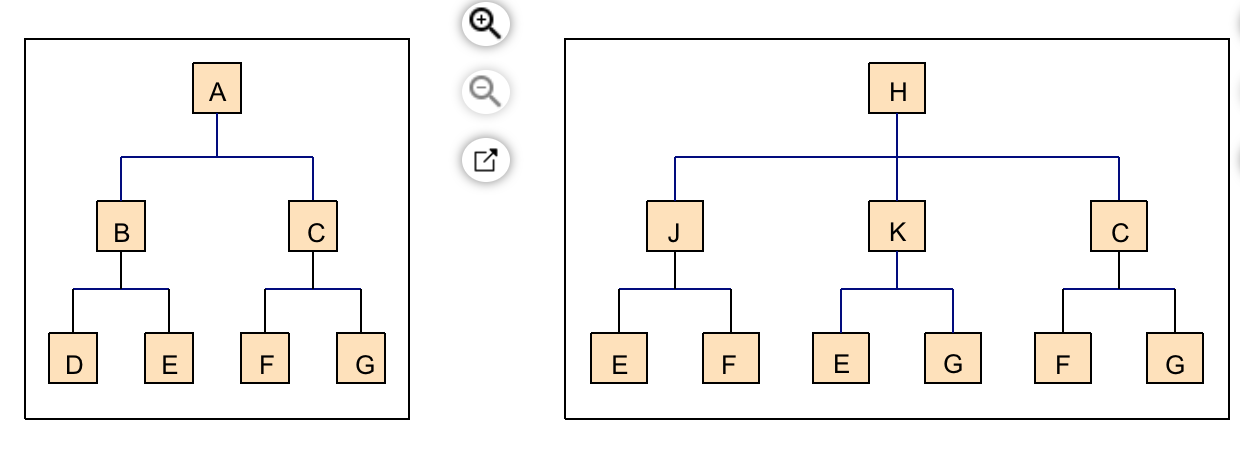

Question: a) Based on the data below,complete a net material requirements schedule for all items (10 schedules in all), assuming the requirement for each Click the

a) Based on the data below,complete a net material requirements schedule for all items (10 schedules in all), assuming the requirement for each

Click the icon to view the product structure, master production schedule and inventory status.

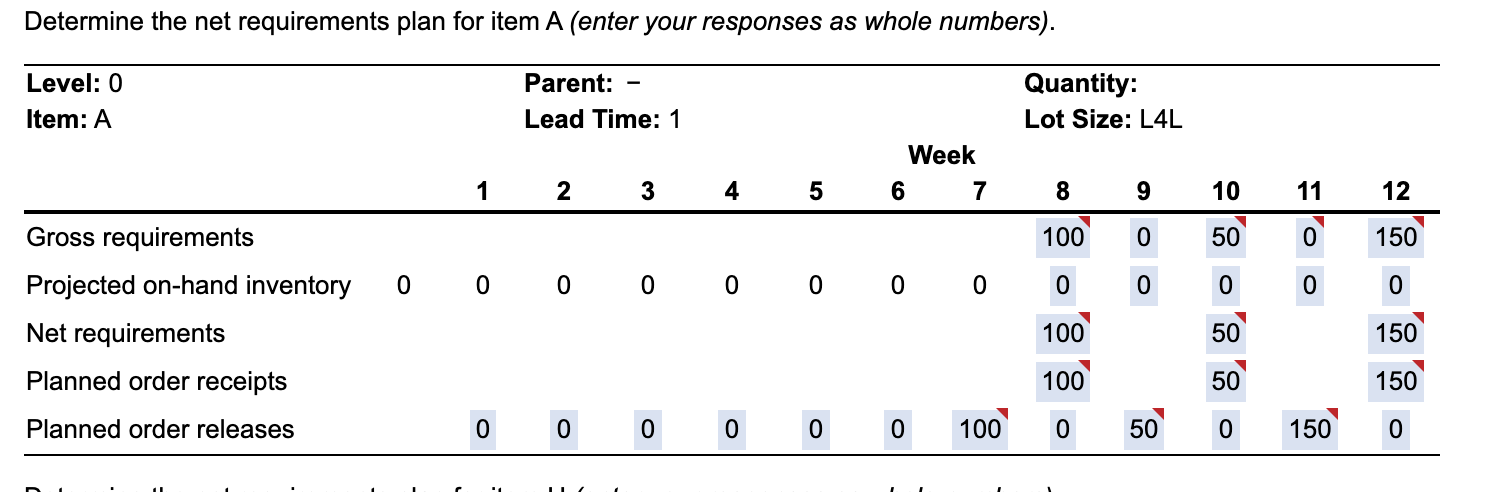

Determine the net requirements plan for item A (enter your responses as whole numbers).

b) Based on the data below,complete a net material requirements schedule for all 10 items, assuming the requirement for all items is 1, except B, C, and F, which require 2 each.

Click the icon to view the product structure, master production schedule and inventory status.

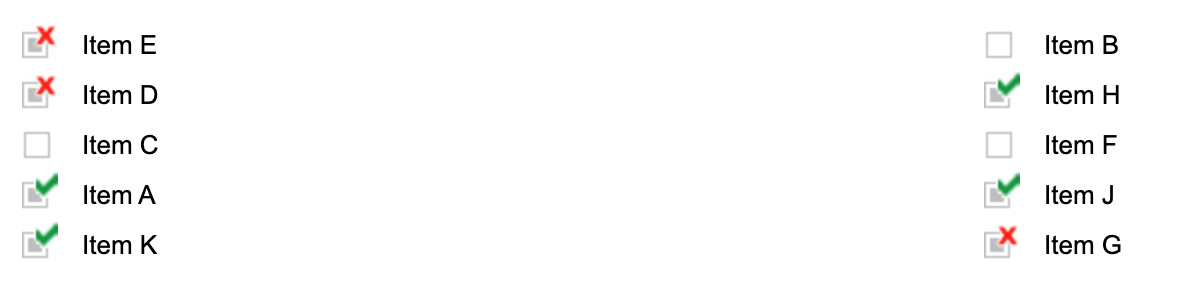

Select all the items which net requirements plan will be the same (if any) below.

Can you please solve and show the work NOT IN EXCEL please....

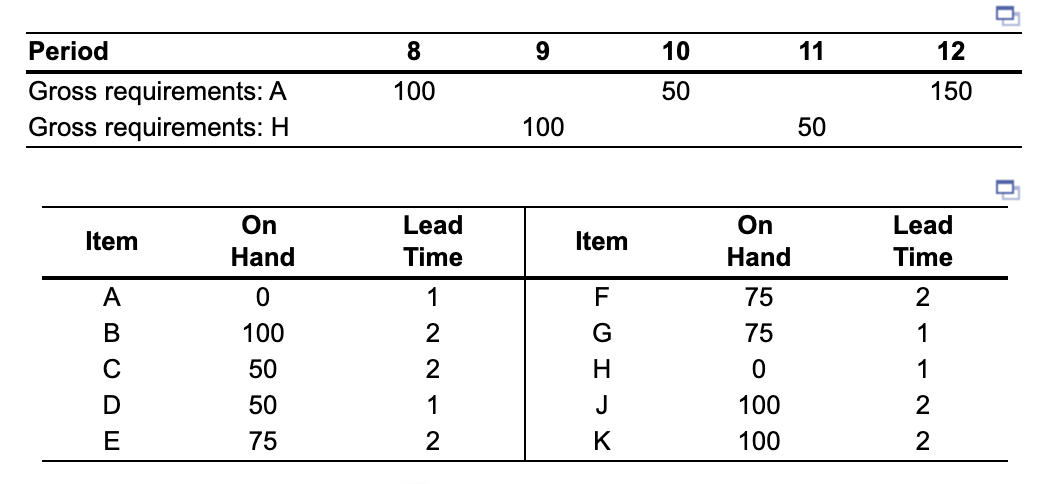

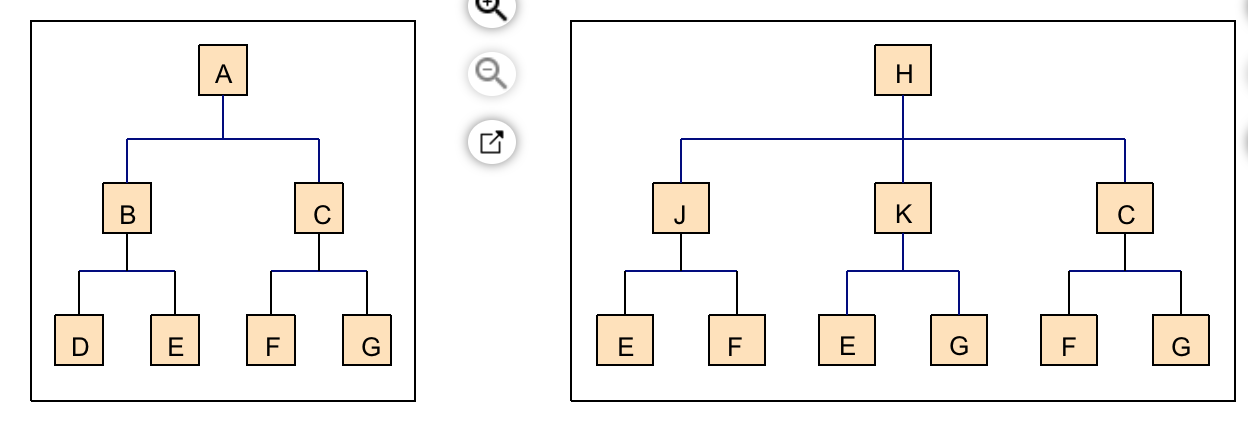

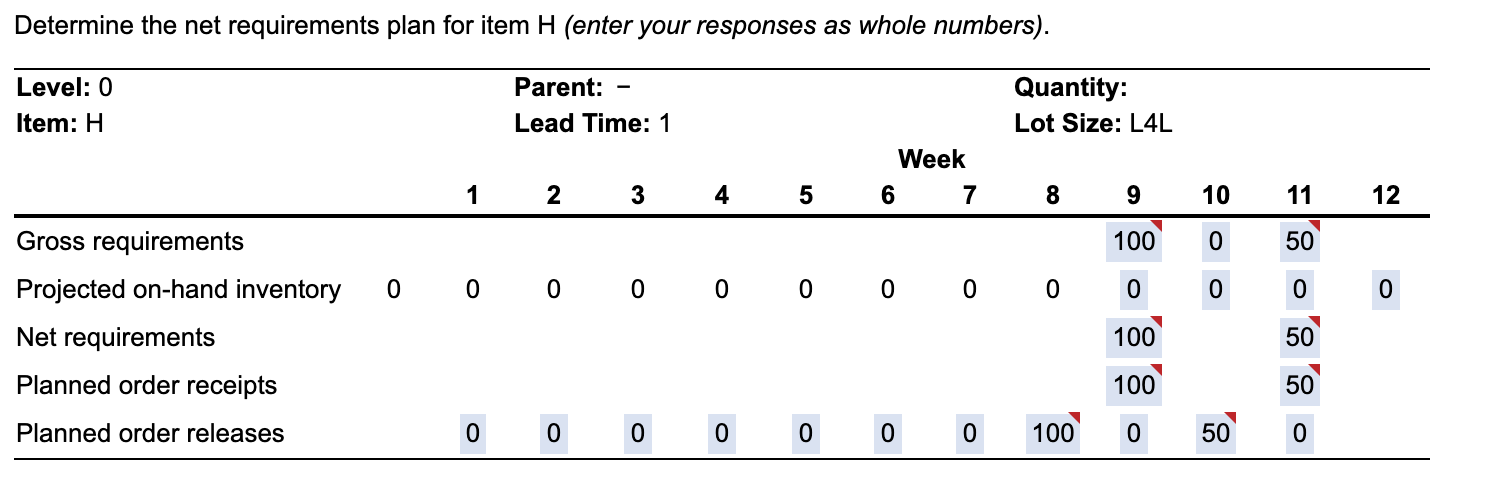

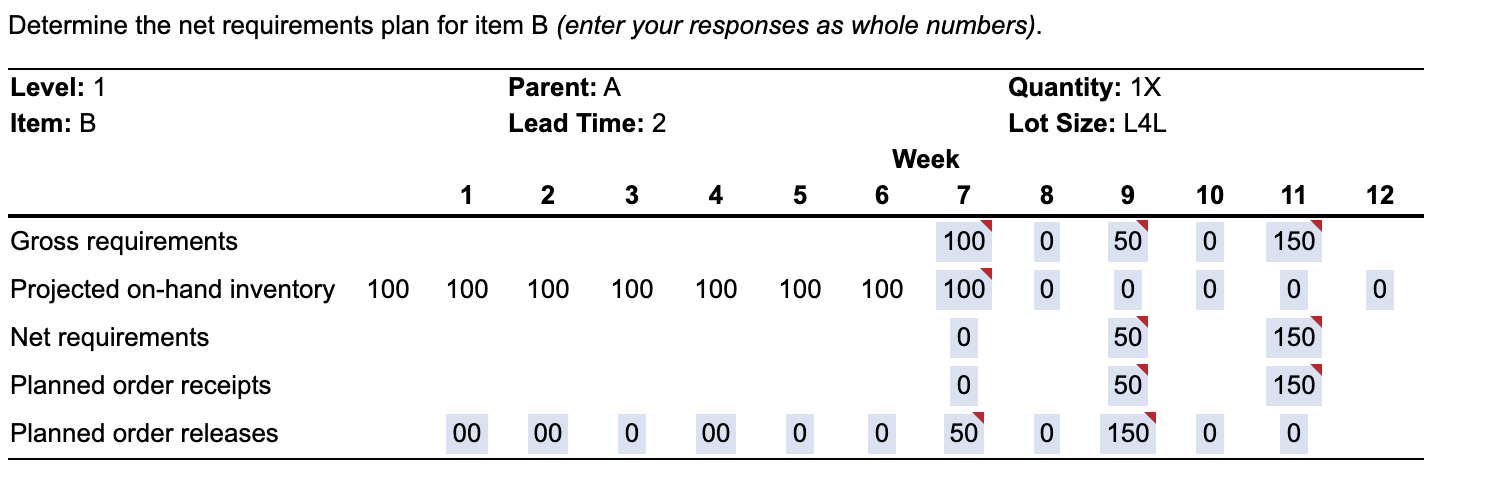

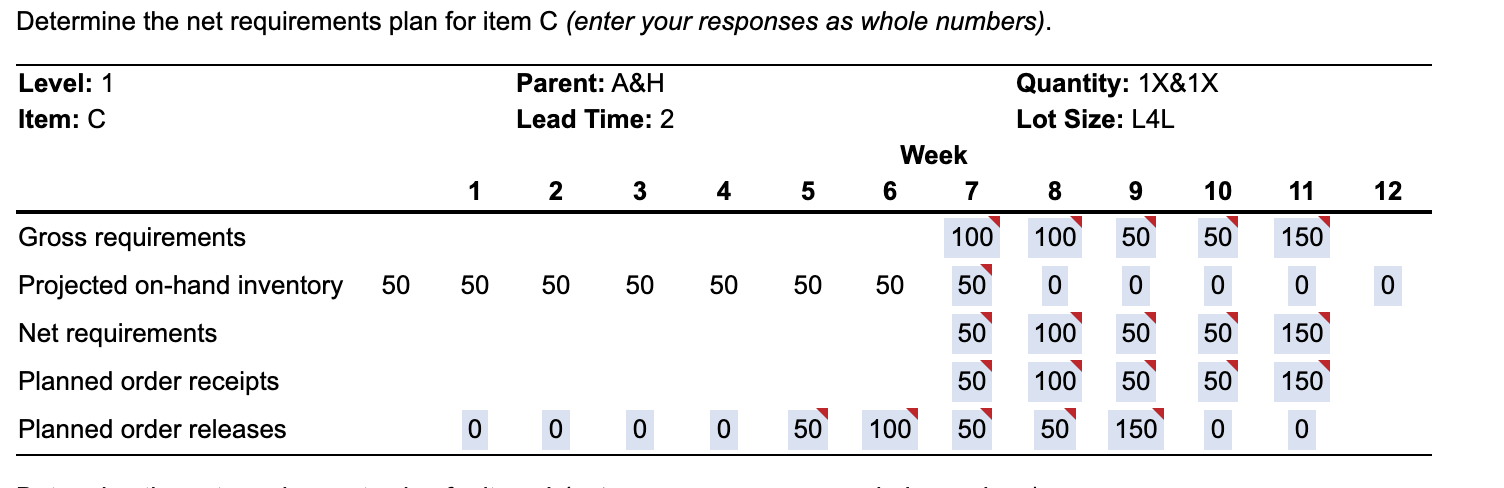

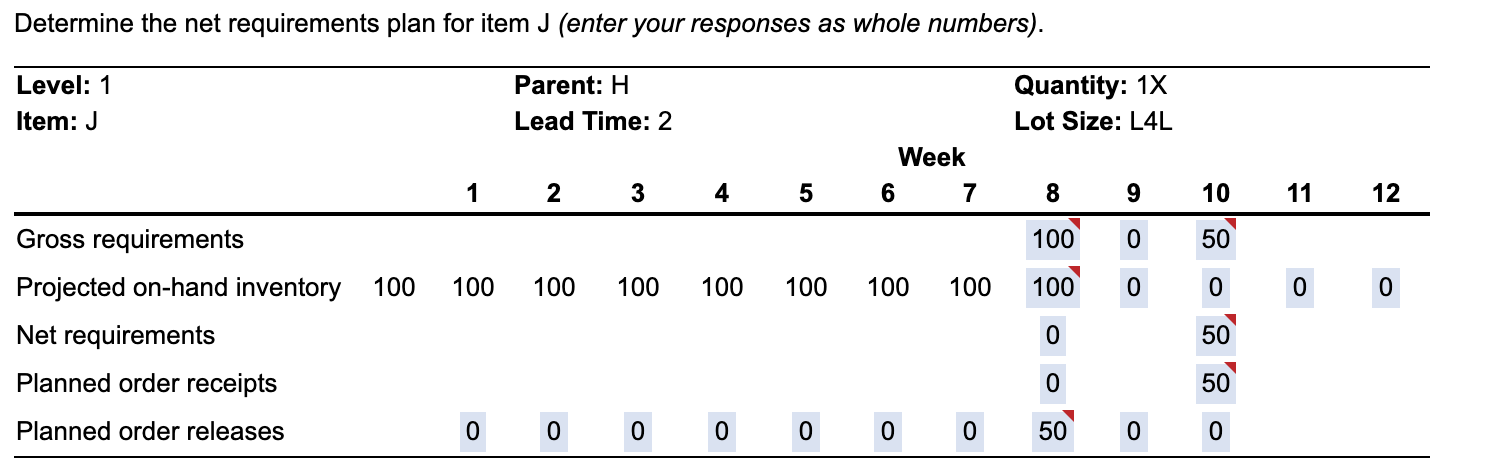

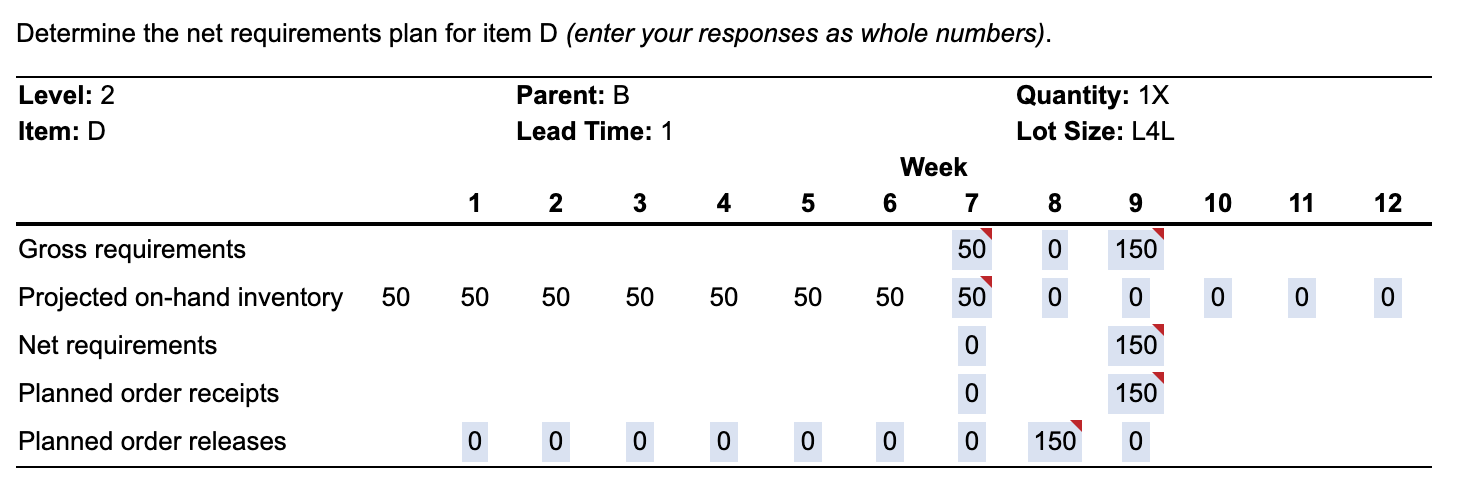

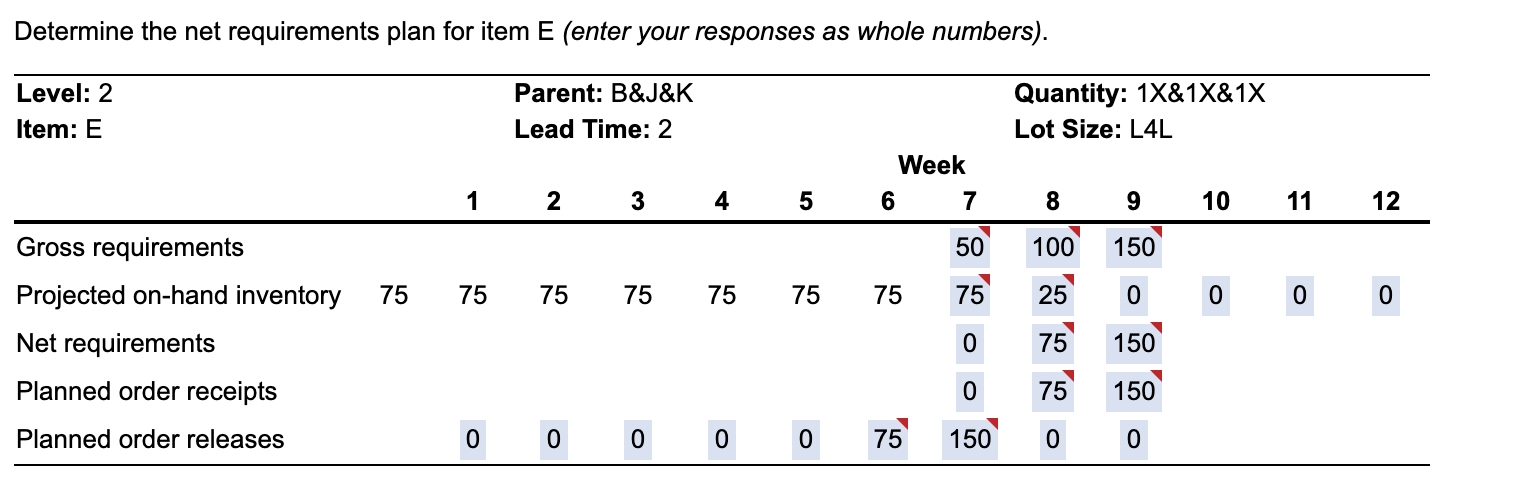

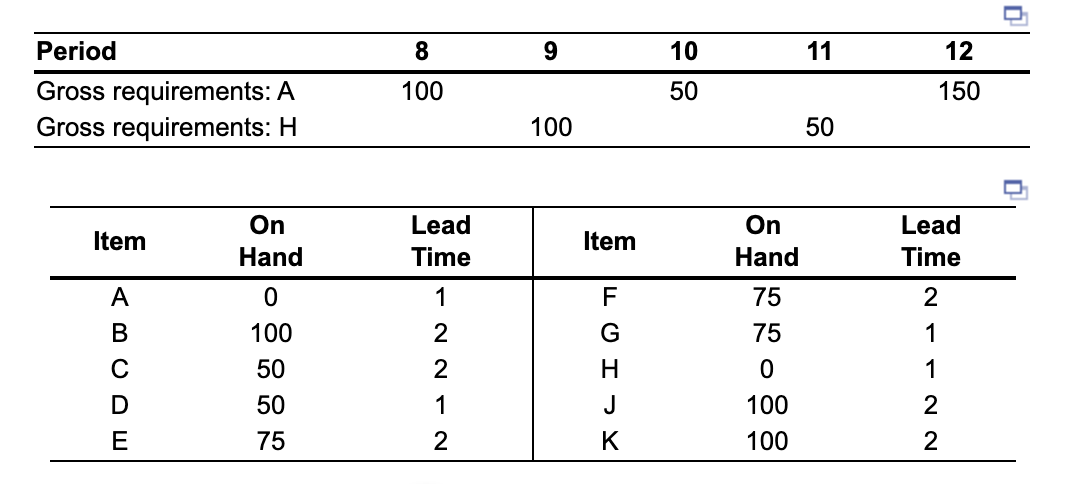

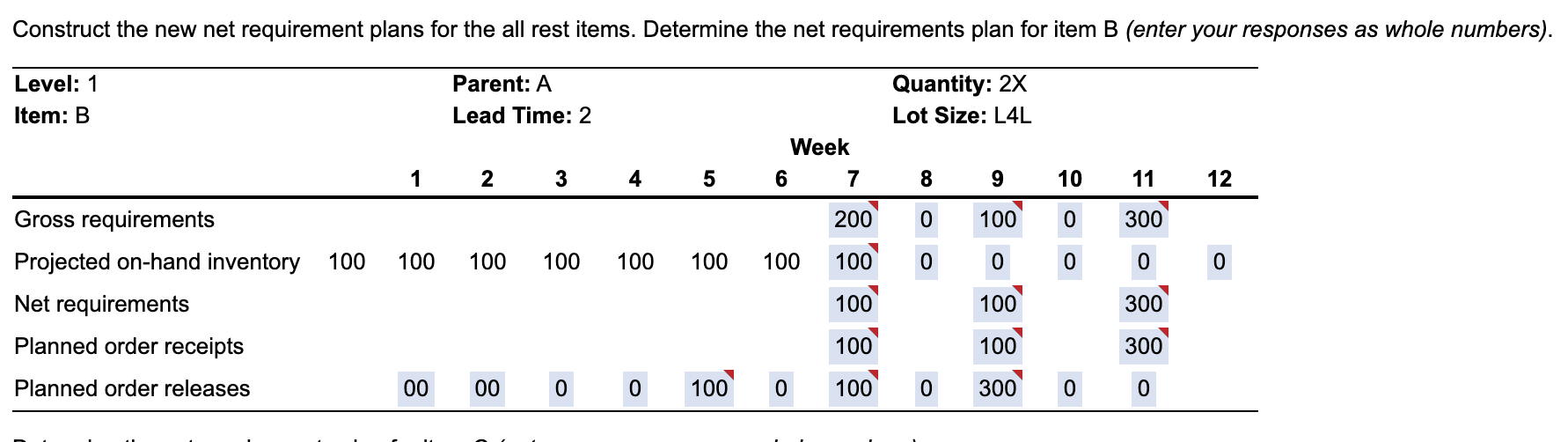

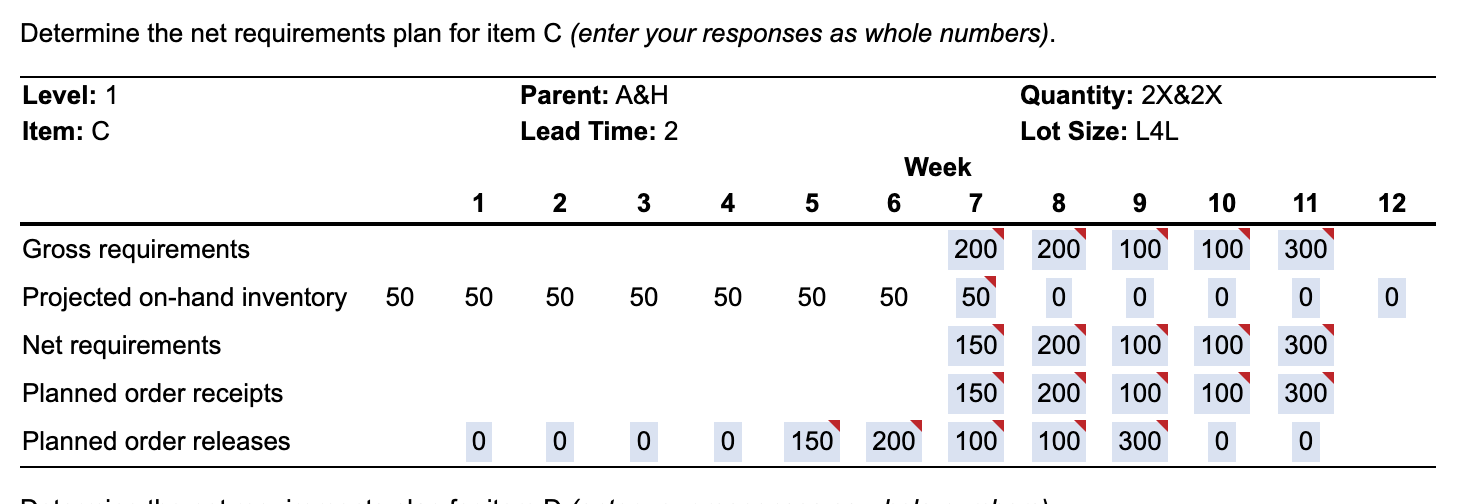

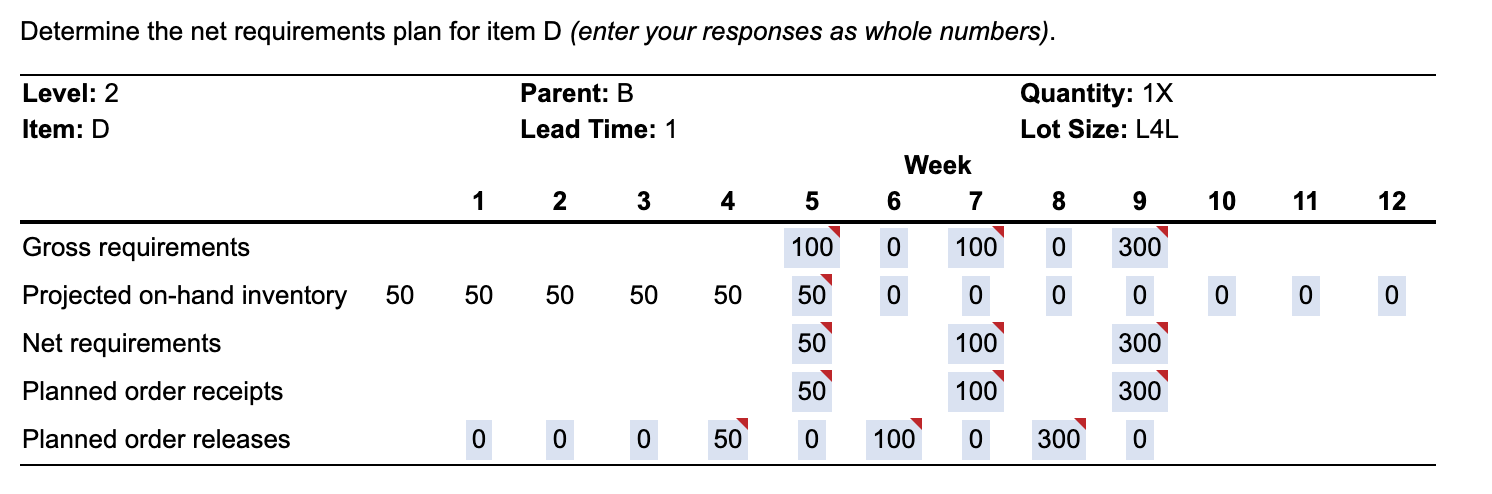

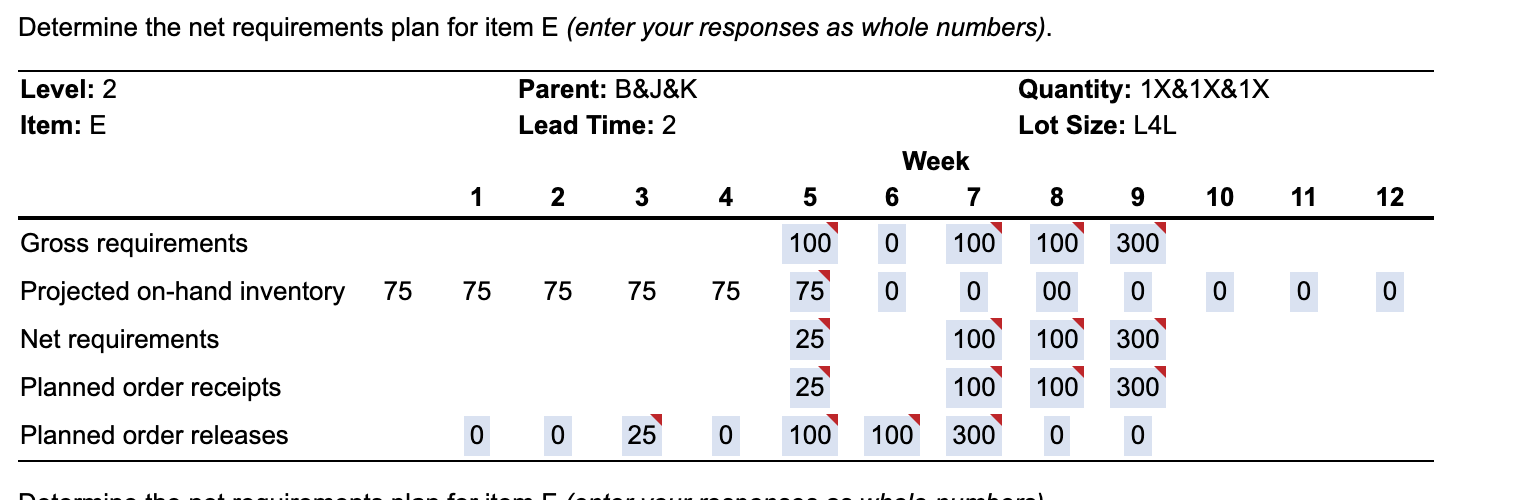

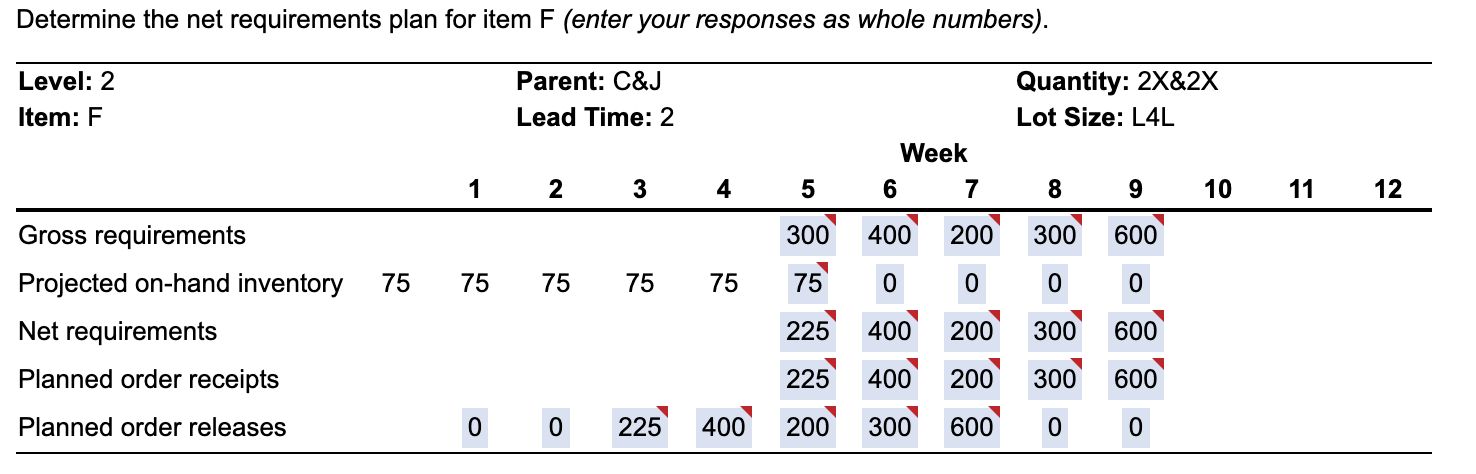

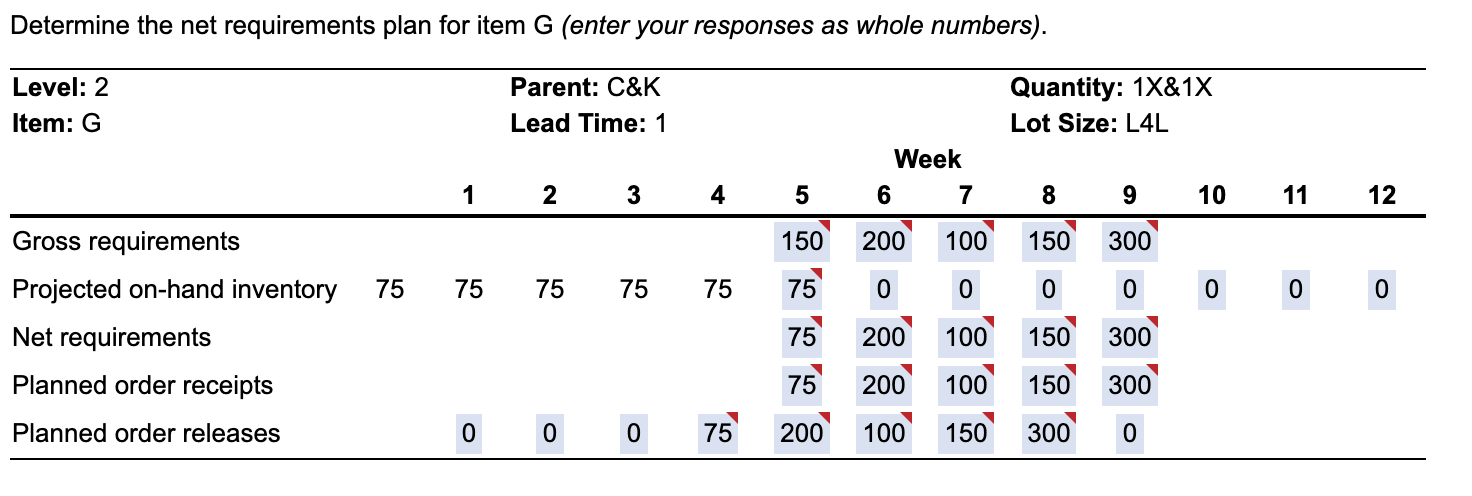

8 9 10 11 12 Period Gross requirements: A Gross requirements: H 100 50 150 100 50 On Item Item Lead Time Hand On Hand 0 100 50 Lead Time 1 2 A F 75 2 B 1 G H D E 1 owg 2 1 2 50 2 100 100 75 2 A H B K E G E F E G G Determine the net requirements plan for item A (enter your responses as whole numbers). Level: 0 Item: A Parent: Lead Time: 1 Quantity: Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 0 150 0 0 0 0 0 0 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 100 50 150 100 50 150 Planned order releases 0 0 0 0 0 O 100 0 50 0 150 0 Determine the net requirements plan for item H (enter your responses as whole numbers). Level: 0 Item: H Parent: Lead Time: 1 Quantity: Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 o o o o 0 0 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 100 50 Planned order releases 0 0 0 0 0 0 0 100 0 50 0 Determine the net requirements plan for item B (enter your responses as whole numbers). Level: 1 Item: B Parent: A Lead Time: 2 Quantity: 1x Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 0 150 100 100 100 100 100 100 100 100 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 150 0 50 150 Planned order releases 00 00 0 0 0 0 50 0 1500 0 Determine the net requirements plan for item C (enter your responses as whole numbers). Level: 1 Item: C Parent: A&H Lead Time: 2 Quantity: 1X&1X Lot Size: L4L Week 5 6 7 1 2 2 3 4 8 9 10 11 12 100 100 50 50 150 50 50 50 50 50 50 50 50 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 50 50 150 50 100 50 50 150 Planned order releases 50 100 50 50 150 0 0 Determine the net requirements plan for item J (enter your responses as whole numbers). Level: 1 Item: J Parent: H Lead Time: 2 Quantity: 1X Lot Size: L4L Week 5 6 7 2 3 4 8 9 10 11 12 100 0 50 100 100 100 100 100 100 100 100 100 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 0 50 Planned order releases 0 o o o o o o 50 0 0 Determine the net requirements plan for item K (enter your responses as whole numbers). Level: 1 Item: K Parent: H Lead Time: 2 Quantity: 1x Lot Size: L4L Week 5 6 7 1 2 3 4 8 9 10 11 12 100 0 50 100 100 100 100 100 100 100 100 100 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 0 50 Planned order releases 0 0 0 0 0 0 0 50 o C 0 Determine the net requirements plan for item D (enter your responses as whole numbers). Level: 2 Item: D Parent: B Lead Time: 1 Quantity: 1x Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 0 150 50 50 50 50 50 50 50 50 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 150 0 150 Planned order releases 0 150 0 Determine the net requirements plan for item E (enter your responses as whole numbers). Level: 2 Item: E Parent: B&J&K Lead Time: 2 Quantity: 1X&1X&1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 100 150 75 75 75 75 75 75 75 75 25 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 150 0 75 150 Planned order releases 0 0 0 0 0 0 75 150 0 0 Determine the net requirements plan for item F (enter your responses as whole numbers). Level: 2 Item: F Parent: C&J Lead Time: 2 Quantity: 1X&1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 100 50 100 150 75 75 75 75 75 75 25 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 50 100 150 0 75 50 100 150 Planned order releases 0 0 0 75 50 100 150 0 0 Determine the net requirements plan for item G (enter your responses as whole numbers). Level: 2 Item: G Parent: C&K Lead Time: 1 Quantity: 1X&1X Lot Size: L4L Week 1 2 3 4 5 6 7 8 9 10 11 12 50 100 50 100 150 75 75 75 75 75 75 25 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 50 100 150 0 75 50 100 150 Planned order releases 0 0 0 0 75 50 100 150 0 8 9 10 11 12 Period Gross requirements: A Gross requirements: H 100 50 150 100 50 On Item Item Lead Time 1 Hand Lead Time 2 A 75 B On Hand 0 100 50 50 75 1 F G H J C D NNN 75 0 100 100 1 2 2 K # A H B K D E F G E F. E G F. Item E Item B Item D Item H Item C Item F Item A Item J Item K Item G Construct the new net requirement plans for the all rest items. Determine the net requirements plan for item B (enter your responses as whole numbers). Level: 1 Item: B Parent: A Lead Time: 2 Quantity: 2 Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12. 200 0 100 0 300 100 100 100 100 100 100 100 100 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 100 100 300 100 100 300 Planned order releases 00 00 0 0 100 0 100 0 300 0 0 Determine the net requirements plan for item C (enter your responses as whole numbers). Parent: A&H Level: 1 Item: C Quantity: 2X&2X Lot Size: L4L Lead Time: 2 Week 6 7 1 2 3 4 5 8 9 10 11 12 200 200 100 100 300 50 50 50 50 50 50 50 50 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 150 200 100 100 300 150 200 100 100 300 Planned order releases 0 0 0 0 150 200 100 100 300 0 0 Determine the net requirements plan for item D (enter your responses as whole numbers). Level: 2 Item: D Parent: B Lead Time: 1 Quantity: 1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 100 0 300 50 50 50 50 50 50 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 300 50 100 300 Planned order releases 0 0 0 0 50 0 100 0 300 0 Determine the net requirements plan for item E (enter your responses as whole numbers). Level: 2 Item: E Parent: B&&K Lead Time: 2 Quantity: 1X&1X&1X Lot Size: L4L Week 5 6 7 1 2 3 4 8 9 10 11 12 100 0 100 100 300 75 75 75 75 75 75 0 0 00 0 0 o 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 25 100 100 300 300 25 100 100 Planned order releases 0 0 25' 0 100 100 300 0 0 Determine the net requirements plan for item F (enter your responses as whole numbers). Level: 2 Item: F Parent: C&J Lead Time: 2 Quantity: 2X&2X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 300 400 200 300 600 75 75 75 75 75 75 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 225 400 200 300 600 225 400 200 300 600 Planned order releases 0 225 400 200 300 600 0 0 Determine the net requirements plan for item G (enter your responses as whole numbers). Level: 2 Item: G Parent: C&K Lead Time: 1 Quantity: 1X&1X Lot Size: L4L Week 6 7 2 3 4 5 8 9 10 11 12 150 200 100 150 300 75 75 75 75 75 75 0 0 0 0 0 O 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 75 200 100 300 75 00 150 100 150 200 100 150 300 Planned order releases 0 O 0 75 200 300 0 8 9 10 11 12 Period Gross requirements: A Gross requirements: H 100 50 150 100 50 On Item Item Lead Time Hand On Hand 0 100 50 Lead Time 1 2 A F 75 2 B 1 G H D E 1 owg 2 1 2 50 2 100 100 75 2 A H B K E G E F E G G Determine the net requirements plan for item A (enter your responses as whole numbers). Level: 0 Item: A Parent: Lead Time: 1 Quantity: Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 0 150 0 0 0 0 0 0 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 100 50 150 100 50 150 Planned order releases 0 0 0 0 0 O 100 0 50 0 150 0 Determine the net requirements plan for item H (enter your responses as whole numbers). Level: 0 Item: H Parent: Lead Time: 1 Quantity: Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 o o o o 0 0 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 100 50 Planned order releases 0 0 0 0 0 0 0 100 0 50 0 Determine the net requirements plan for item B (enter your responses as whole numbers). Level: 1 Item: B Parent: A Lead Time: 2 Quantity: 1x Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 50 0 150 100 100 100 100 100 100 100 100 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 150 0 50 150 Planned order releases 00 00 0 0 0 0 50 0 1500 0 Determine the net requirements plan for item C (enter your responses as whole numbers). Level: 1 Item: C Parent: A&H Lead Time: 2 Quantity: 1X&1X Lot Size: L4L Week 5 6 7 1 2 2 3 4 8 9 10 11 12 100 100 50 50 150 50 50 50 50 50 50 50 50 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 50 50 150 50 100 50 50 150 Planned order releases 50 100 50 50 150 0 0 Determine the net requirements plan for item J (enter your responses as whole numbers). Level: 1 Item: J Parent: H Lead Time: 2 Quantity: 1X Lot Size: L4L Week 5 6 7 2 3 4 8 9 10 11 12 100 0 50 100 100 100 100 100 100 100 100 100 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 0 50 Planned order releases 0 o o o o o o 50 0 0 Determine the net requirements plan for item K (enter your responses as whole numbers). Level: 1 Item: K Parent: H Lead Time: 2 Quantity: 1x Lot Size: L4L Week 5 6 7 1 2 3 4 8 9 10 11 12 100 0 50 100 100 100 100 100 100 100 100 100 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 50 0 50 Planned order releases 0 0 0 0 0 0 0 50 o C 0 Determine the net requirements plan for item D (enter your responses as whole numbers). Level: 2 Item: D Parent: B Lead Time: 1 Quantity: 1x Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 0 150 50 50 50 50 50 50 50 50 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 150 0 150 Planned order releases 0 150 0 Determine the net requirements plan for item E (enter your responses as whole numbers). Level: 2 Item: E Parent: B&J&K Lead Time: 2 Quantity: 1X&1X&1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 100 150 75 75 75 75 75 75 75 75 25 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 150 0 75 150 Planned order releases 0 0 0 0 0 0 75 150 0 0 Determine the net requirements plan for item F (enter your responses as whole numbers). Level: 2 Item: F Parent: C&J Lead Time: 2 Quantity: 1X&1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 50 100 50 100 150 75 75 75 75 75 75 25 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 50 100 150 0 75 50 100 150 Planned order releases 0 0 0 75 50 100 150 0 0 Determine the net requirements plan for item G (enter your responses as whole numbers). Level: 2 Item: G Parent: C&K Lead Time: 1 Quantity: 1X&1X Lot Size: L4L Week 1 2 3 4 5 6 7 8 9 10 11 12 50 100 50 100 150 75 75 75 75 75 75 25 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 0 75 50 100 150 0 75 50 100 150 Planned order releases 0 0 0 0 75 50 100 150 0 8 9 10 11 12 Period Gross requirements: A Gross requirements: H 100 50 150 100 50 On Item Item Lead Time 1 Hand Lead Time 2 A 75 B On Hand 0 100 50 50 75 1 F G H J C D NNN 75 0 100 100 1 2 2 K # A H B K D E F G E F. E G F. Item E Item B Item D Item H Item C Item F Item A Item J Item K Item G Construct the new net requirement plans for the all rest items. Determine the net requirements plan for item B (enter your responses as whole numbers). Level: 1 Item: B Parent: A Lead Time: 2 Quantity: 2 Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12. 200 0 100 0 300 100 100 100 100 100 100 100 100 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 100 100 300 100 100 300 Planned order releases 00 00 0 0 100 0 100 0 300 0 0 Determine the net requirements plan for item C (enter your responses as whole numbers). Parent: A&H Level: 1 Item: C Quantity: 2X&2X Lot Size: L4L Lead Time: 2 Week 6 7 1 2 3 4 5 8 9 10 11 12 200 200 100 100 300 50 50 50 50 50 50 50 50 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 150 200 100 100 300 150 200 100 100 300 Planned order releases 0 0 0 0 150 200 100 100 300 0 0 Determine the net requirements plan for item D (enter your responses as whole numbers). Level: 2 Item: D Parent: B Lead Time: 1 Quantity: 1X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 100 0 100 0 300 50 50 50 50 50 50 0 0 0 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 50 100 300 50 100 300 Planned order releases 0 0 0 0 50 0 100 0 300 0 Determine the net requirements plan for item E (enter your responses as whole numbers). Level: 2 Item: E Parent: B&&K Lead Time: 2 Quantity: 1X&1X&1X Lot Size: L4L Week 5 6 7 1 2 3 4 8 9 10 11 12 100 0 100 100 300 75 75 75 75 75 75 0 0 00 0 0 o 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 25 100 100 300 300 25 100 100 Planned order releases 0 0 25' 0 100 100 300 0 0 Determine the net requirements plan for item F (enter your responses as whole numbers). Level: 2 Item: F Parent: C&J Lead Time: 2 Quantity: 2X&2X Lot Size: L4L Week 6 7 1 2 3 4 5 8 9 10 11 12 300 400 200 300 600 75 75 75 75 75 75 0 0 0 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 225 400 200 300 600 225 400 200 300 600 Planned order releases 0 225 400 200 300 600 0 0 Determine the net requirements plan for item G (enter your responses as whole numbers). Level: 2 Item: G Parent: C&K Lead Time: 1 Quantity: 1X&1X Lot Size: L4L Week 6 7 2 3 4 5 8 9 10 11 12 150 200 100 150 300 75 75 75 75 75 75 0 0 0 0 0 O 0 Gross requirements Projected on-hand inventory Net requirements Planned order receipts 75 200 100 300 75 00 150 100 150 200 100 150 300 Planned order releases 0 O 0 75 200 300 0Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts